Ruthenium oxide coated titanium anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

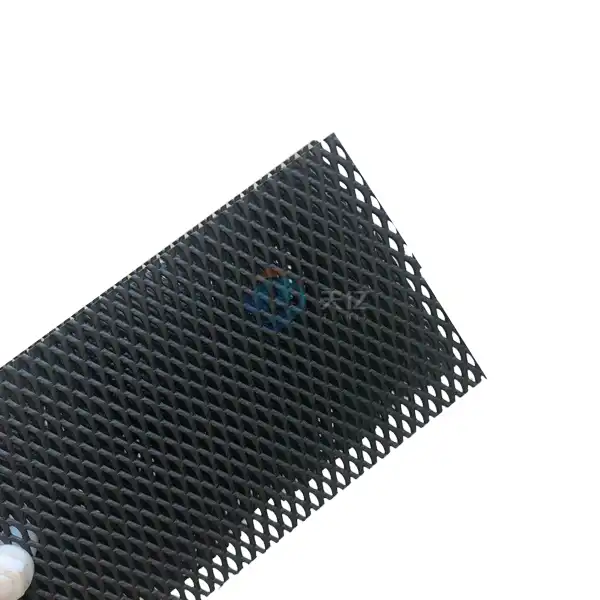

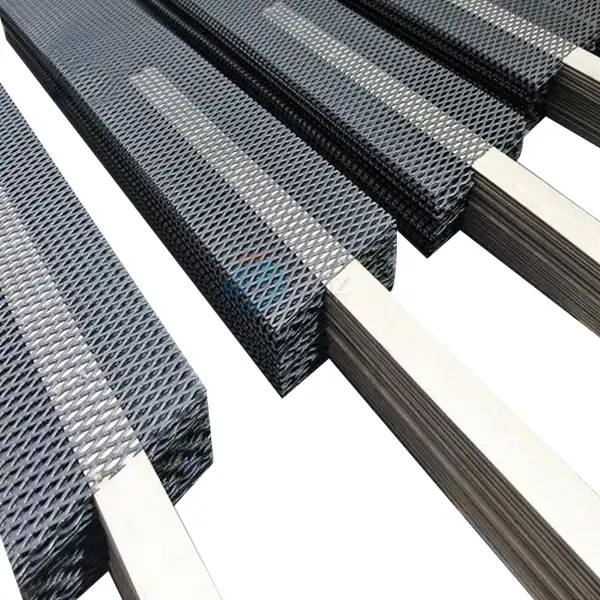

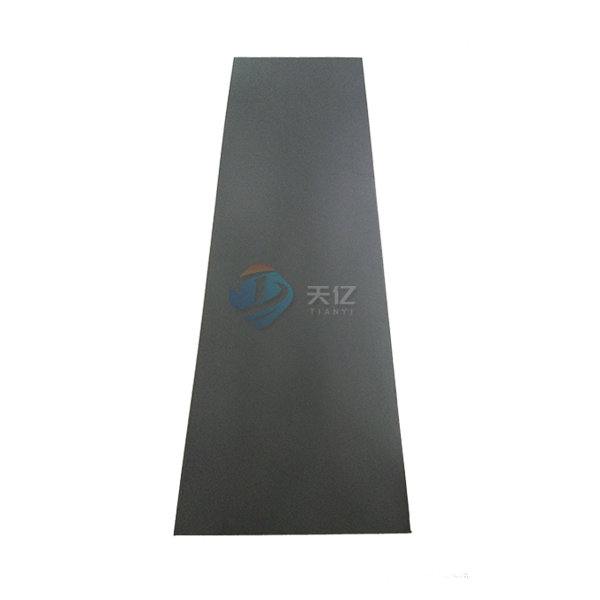

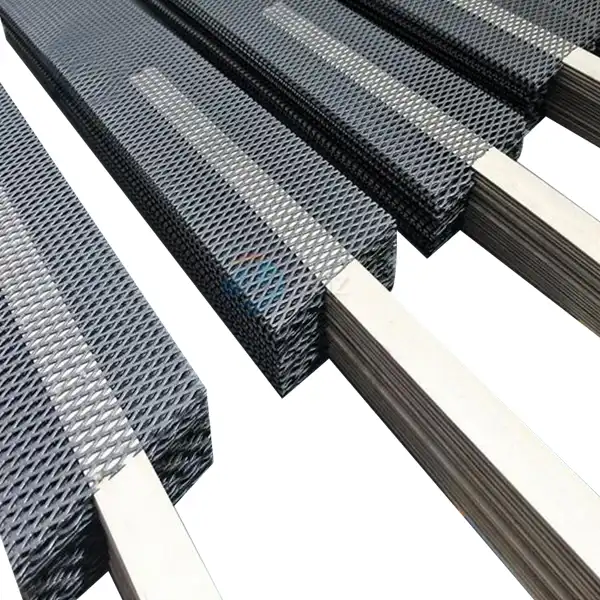

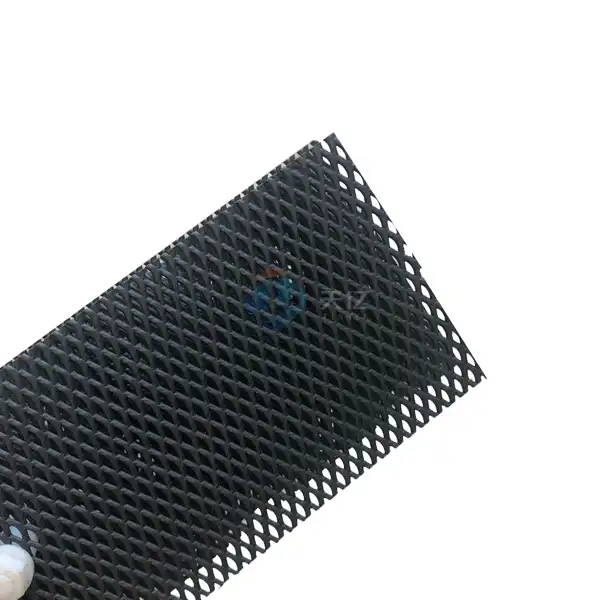

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to our product page for the Ruthenium Oxide Coated Titanium Anode! At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we pride ourselves on producing high-performance electrochemical materials that meet the demanding needs of various industries. Our ruthenium oxide coated titanium anodes are engineered for durability, efficiency, and exceptional performance in diverse applications.

Product Specifications

Material | Gr1 Titanium as substrate, MMO as coating |

Coating Types | RuO2 +IRO2 +X |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | <24V |

Current Density | <5,000A/㎡ |

Work time | 80-120 H |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 8~15μm |

Product Composition and Design

The Ruthenium Oxide Coated Titanium Anode consists of a titanium substrate coated with a ruthenium oxide layer. This innovative design enhances corrosion resistance and improves electrochemical stability, making it ideal for demanding environments such as water treatment and electroplating.

Product Advantages

High Durability:Ruthenium oxide is known for its exceptional corrosion resistance, which significantly extends the lifespan of the anode. This durability ensures that the anode maintains its performance over time, reducing the need for frequent replacements and minimizing maintenance costs.

Efficiency:Ruthenium oxide offers superior electrochemical performance, which translates to reduced energy consumption in various applications. This high efficiency not only enhances the overall effectiveness of the system but also contributes to lower operational costs.

Customization:We understand that each client has unique requirements, which is why we offer tailored specifications for our coatings and anodes. This customization allows us to meet specific performance criteria and environmental conditions, ensuring that our solutions align perfectly with the individual needs of our clients and enhance their operational effectiveness.

Environmentally Friendly:Our use of ruthenium oxide supports sustainable practices across various industries. By focusing on materials and processes that minimize environmental impact, we contribute to greener solutions that align with modern sustainability goals.

Technical Features

- Robust Construction: Engineered with materials specifically chosen to withstand harsh chemical environments, ensuring durability and resilience. This construction minimizes wear and tear, allowing the system to perform reliably in challenging conditions, such as exposure to corrosive substances or extreme temperatures.

- Versatile Applications: Highly suitable for a wide range of applications, including electroplating, water treatment, and cathodic protection. Its adaptability makes it ideal for various industries, from manufacturing and wastewater management to energy and environmental sectors, providing flexible solutions to meet diverse operational needs.

- High Current Density: Capable of operating efficiently at high current densities without degradation, this technology ensures optimal performance and energy efficiency. Its design allows for sustained operations under intense conditions, making it an excellent choice for applications requiring high power output while maintaining structural integrity and performance over time.

Product Application

Our ruthenium oxide coated titanium anodes are used in:

1. Fruit and vegetable disinfection machine

2. Sodium hypochlorite production

3. Chlor-alkali industry

4. Swimming pool water disinfection

5. Wastewater treatment

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our manufacturing process is meticulous and involves:

Titanium Substrate Selection

High-grade titanium substrates are selected for their excellent mechanical properties and corrosion resistance, which are essential for the durability and functionality of the anodes in electrochemical applications.

Surface Treatment

The titanium surfaces are meticulously prepared through processes like grit blasting and acid cleaning. This treatment removes impurities and enhances surface roughness, promoting better adhesion of the ruthenium oxide coating.

Oxide Preparation

A ruthenium oxide solution is prepared using high-purity ruthenium compounds. The solution may be optimized with additives to enhance the coating's electrical properties and overall performance.

Coating Application

The ruthenium oxide solution is applied to the prepared titanium substrate using methods such as dip-coating or electrochemical deposition. These methods allow for precise control over the thickness and uniformity of the coating.

Curing Process

The coated anodes undergo a curing process, typically involving heat treatment. This step promotes the formation of a stable and adherent oxide layer, enhancing the anode's electrochemical properties and durability.

Performance Evaluation

Each anode is rigorously tested for electrochemical performance, including measuring catalytic activity and stability under operational conditions. This evaluation ensures that the anodes meet specific performance standards.

Final Inspection and Packaging

After testing, the anodes are inspected for any defects before being packaged in protective materials to prevent damage during transport. Each package includes product specifications, handling instructions, and safety information for users.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Each anode undergoes stringent inspections for:

- Thickness and uniformity of the coating.

- Electrochemical performance tests.

- Corrosion resistance evaluations.

Packaging Method

We prioritize safe and efficient packaging, utilizing:

- Custom Foam Inserts: To prevent damage during transit.

- Sealed Containers: Ensuring protection against moisture and contaminants.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services to meet your specific needs. Whether you require unique specifications or tailored solutions, our team is here to assist.

FAQ

Q: What is the expected lifespan of the ruthenium oxide coated titanium anode?

A: The anode can last between 5 to 10 years, depending on the application and operating conditions.

Q: Can I customize the dimensions of the anode?

A: Yes, we provide fully customizable solutions to fit your specific requirements.

Q: What industries can benefit from this product?

A: Our anodes are used in water treatment, electroplating, hydrometallurgy, and more.

Contact Us

For more information or to place an order, please reach out to us at [info@di-nol.com]. Our dedicated team is ready to provide you with the best solutions in electrochemical technology!

YOU MAY LIKE

VIEW MOREplatinum coated titanium anode

VIEW MOREplatinum coated titanium anode VIEW MORERuthenium-iridium coated titanium anode

VIEW MORERuthenium-iridium coated titanium anode VIEW MOREPowered Water Heater Anode Rod

VIEW MOREPowered Water Heater Anode Rod VIEW MORERuthenium-iridium oxide coated titanium anode

VIEW MORERuthenium-iridium oxide coated titanium anode VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode VIEW MOREmixed metal oxide coated titanium anodes

VIEW MOREmixed metal oxide coated titanium anodes VIEW MOREiridium oxide coated titanium anodes

VIEW MOREiridium oxide coated titanium anodes VIEW MOREanodic coating titanium

VIEW MOREanodic coating titanium