Powered Water Heater Anode Rod

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Product Introduction

Welcome to the ultimate solution for enhancing the lifespan and performance of your powered water heater—the Powered Water Heater Anode Rod. This crucial component protects your water heater tank from corrosion, ensuring it operates efficiently while prolonging its life. With our anode rod, you can enjoy clean, hot water while safeguarding your investment.

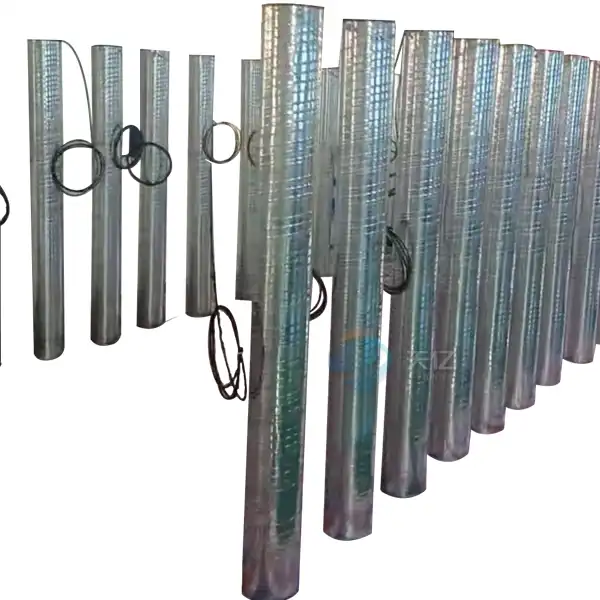

Product Show

Product Composition and Design

Our Powered Water Heater Anode Rod is made from high-grade aluminum or magnesium, selected for its superior corrosion resistance. The rod's unique design allows for easy installation and replacement, fitting seamlessly into most powered water heater models. Its robust construction ensures it withstands harsh conditions, maximizing durability.

Product Advantages

- Corrosion Protection: Acts as a sacrificial anode, preventing rust formation on your water heater tank.

- Cost-Effective: Extends the lifespan of your water heater, saving you from costly replacements.

- Easy Installation: Designed for quick and hassle-free installation, making maintenance a breeze.

Technical Features

- Lightweight yet Durable: Crafted from materials that combine strength with low weight, facilitating ease of handling.

- Versatile Compatibility: Compatible with a wide range of powered water heater brands and models.

- Sustainable Design: Contributes to environmentally friendly practices by reducing waste and promoting longevity.

Product Application

1. Marine industry

2. Oil and gas industry

3. Construction and infrastructure

4. Utilities and water treatment

5. Energy sector

6. Public infrastructure development

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our anode rods undergo a meticulous production process that includes:

Material Selection

The production of powered water heater anode rods begins with selecting high-quality metals, typically aluminum, magnesium, or zinc. These materials are chosen for their sacrificial properties, which help prevent corrosion in the water heater tank by corroding themselves instead of the tank.

Rod Design and Specifications

Engineers design the anode rods to specific lengths and diameters based on common water heater models. Detailed specifications ensure compatibility with various heater designs, optimizing performance and longevity.

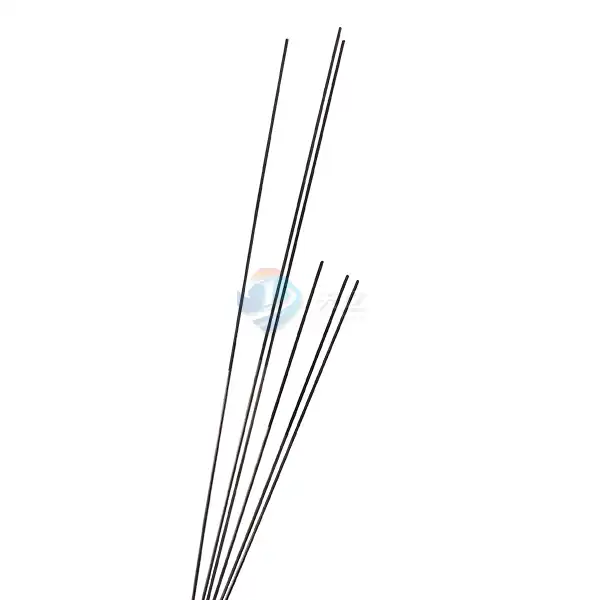

Rod Fabrication

The selected metal is fabricated into rods using extrusion or machining techniques. This process shapes the metal into the desired form while ensuring uniformity in dimensions, which is crucial for fitting into the water heater tank.

Surface Preparation

Each rod undergoes surface preparation, including cleaning and de-burring, to remove any oxides, dirt, or contaminants. This step enhances the rod's effectiveness by ensuring maximum surface area for electrochemical reactions.

Coating Application (if applicable)

Depending on the design, some anode rods may receive a protective coating to enhance corrosion resistance or improve performance in specific water conditions. This coating is applied through methods such as electroplating or powder coating.

Quality Control Testing

Quality control is vital throughout the production process. Each batch of anode rods is tested for dimensional accuracy, material properties, and coating integrity. This ensures that the rods meet industry standards and performance expectations.

Final Inspection

After production and testing, a final inspection is conducted to check for any defects, ensuring that only high-quality anode rods proceed to packaging. This step confirms the rods meet specifications for durability and performance.

Packaging

The powered water heater anode rods are carefully packaged to prevent damage during shipping. Packaging materials are chosen to protect the rods from impact and corrosion, ensuring they arrive at their destination in perfect condition.

Documentation and Certification

Each package includes documentation that outlines the specifications, installation guidelines, and warranty information. This ensures customers understand how to install and maintain the anode rods effectively.

Shipping Logistics

The packaged anode rods are shipped using reliable logistics services, ensuring timely delivery. Customers receive tracking information for transparency throughout the shipping process.

Post-Delivery Support

After delivery, customers have access to technical support for installation and maintenance questions. This ongoing support helps ensure that the anode rods function effectively and prolong the life of the water heater.

Through this detailed production process, powered water heater anode rods are engineered to provide optimal corrosion protection, significantly extending the lifespan of water heater tanks and ensuring reliable performance in various water conditions.

Material Selection

The production of powered water heater anode rods begins with selecting high-quality metals, typically aluminum, magnesium, or zinc. These materials are chosen for their sacrificial properties, which help prevent corrosion in the water heater tank by corroding themselves instead of the tank.

Rod Design and Specifications

Engineers design the anode rods to specific lengths and diameters based on common water heater models. Detailed specifications ensure compatibility with various heater designs, optimizing performance and longevity.

Rod Fabrication

The selected metal is fabricated into rods using extrusion or machining techniques. This process shapes the metal into the desired form while ensuring uniformity in dimensions, which is crucial for fitting into the water heater tank.

Surface Preparation

Each rod undergoes surface preparation, including cleaning and de-burring, to remove any oxides, dirt, or contaminants. This step enhances the rod's effectiveness by ensuring maximum surface area for electrochemical reactions.

Coating Application (if applicable)

Depending on the design, some anode rods may receive a protective coating to enhance corrosion resistance or improve performance in specific water conditions. This coating is applied through methods such as electroplating or powder coating.

Quality Control Testing

Quality control is vital throughout the production process. Each batch of anode rods is tested for dimensional accuracy, material properties, and coating integrity. This ensures that the rods meet industry standards and performance expectations.

Final Inspection

After production and testing, a final inspection is conducted to check for any defects, ensuring that only high-quality anode rods proceed to packaging. This step confirms the rods meet specifications for durability and performance.

Packaging

The powered water heater anode rods are carefully packaged to prevent damage during shipping. Packaging materials are chosen to protect the rods from impact and corrosion, ensuring they arrive at their destination in perfect condition.

Documentation and Certification

Each package includes documentation that outlines the specifications, installation guidelines, and warranty information. This ensures customers understand how to install and maintain the anode rods effectively.

Shipping Logistics

The packaged anode rods are shipped using reliable logistics services, ensuring timely delivery. Customers receive tracking information for transparency throughout the shipping process.

Post-Delivery Support

After delivery, customers have access to technical support for installation and maintenance questions. This ongoing support helps ensure that the anode rods function effectively and prolong the life of the water heater.

Through this detailed production process, powered water heater anode rods are engineered to provide optimal corrosion protection, significantly extending the lifespan of water heater tanks and ensuring reliable performance in various water conditions.

Quality Inspection

We employ rigorous quality control measures throughout the production process. Each rod is tested for:

- Corrosion Resistance: Ensuring longevity and effectiveness in protecting your water heater.

- Dimensional Accuracy: Confirming that all specifications are met for perfect compatibility.

Packaging Method

Our Powered Water Heater Anode Rod are securely packaged to prevent damage during transit. Each rod is wrapped in protective materials and placed in sturdy boxes, ensuring they arrive in perfect condition. We meticulously develop custom packaging solutions that prioritize both safety and cost-effectiveness. Each anode we produce is meticulously packaged to prevent any damage during transit, ensuring that it reaches our customers in pristine condition.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services for businesses looking to customize their anode rods. Whether you need specific sizes, materials, or branding options, we can accommodate your requirements to deliver products tailored to your market. We offer comprehensive OEM services tailored to meet the specific needs of businesses seeking customized anode rods. Our expertise allows us to cater to a variety of requirements, including unique sizes, specialized materials, and personalized branding options.

FAQ

Q: How often should I replace my anode rod?

A: It's recommended to check the anode rod annually and replace it every 3-5 years, depending on water quality.

Q: Will this anode rod fit my water heater?

A: Our anode rods are designed to fit most powered water heater models. Please check dimensions for compatibility.

Q: Can I install the anode rod myself?

A: Yes, installation is straightforward, and detailed instructions are included with your purchase.

Contact Us

For more information about the Powered Water Heater Anode Rod or to place an order, please contact us at [info@di-nol.com]. Our team is ready to assist you with any inquiries and provide the best solutions for your needs.

_1731573049210.webp)