ICCP MMO Canister Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Product Introduction

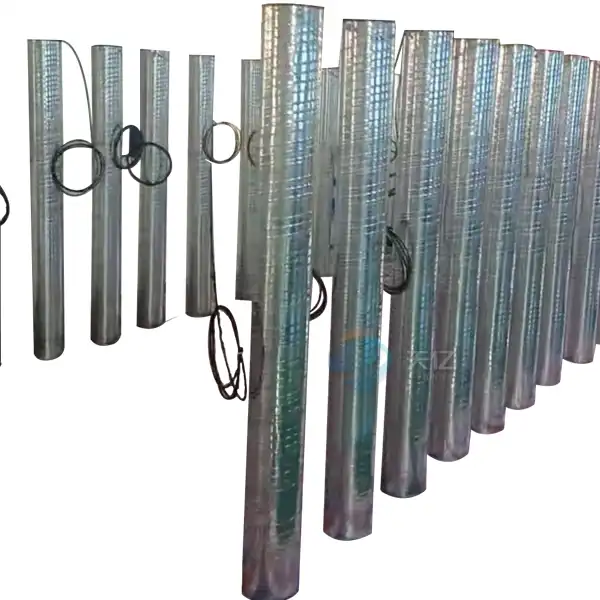

The ICCP MMO Canister Anode is a high-performance electrochemical solution specifically designed for impressed current cathodic protection (ICCP) systems. These anodes are crafted from mixed metal oxide (MMO) coatings, ensuring exceptional durability and resistance to corrosion. Ideal for protecting pipelines, tanks, and other metal structures from electrochemical deterioration, our canister anodes deliver long-lasting performance, contributing significantly to asset longevity and safety in various industrial applications.

Product Specifications

Cylinder length (mm) | Cylinder outer diameter (mm) | Anode length (mm) | Cable Type |

1000 | 80 | 800 | PVDF/HMWPE |

1500 | 100 | 1200 | PVDF/HMWPE |

2000 | 150 | 1800 | PVDF/HMWPE |

|  |

|  |

|  |

Product Composition and Design

The ICCP MMO Canister Anode features a robust design, utilizing high-quality titanium substrates coated with a proprietary MMO formulation. This composition enhances the anode’s resistance to corrosion, ensuring effective protection even in challenging environments. The canister design allows for easy installation and integration into existing cathodic protection systems, making it a versatile choice for various applications.

Product Advantages

- Durability: Designed to withstand harsh environments, ensuring long-lasting protection.

- Cost-Effectiveness: Extended service life translates to lower replacement costs over time.

- High Efficiency: Optimized for high current densities, maximizing protection.

- Customizable: Tailored dimensions and specifications to meet unique project requirements.

Technical Features

- Advanced MMO Coating: Provides superior electrochemical properties, enhancing performance.

- Lightweight Design: Facilitates easier handling and installation.

- Corrosion Resistance: Ensures reliability and performance in diverse environments.

Product Applications

The ICCP MMO Canister Anode is suitable for various industries, including:

1. Marine industry

2. Oil and gas industry

3. Construction and infrastructure

4. Utilities and water treatment

5. Energy sector

6. Public infrastructure development

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our ICCP MMO Canister Anodes are manufactured using advanced techniques that include:

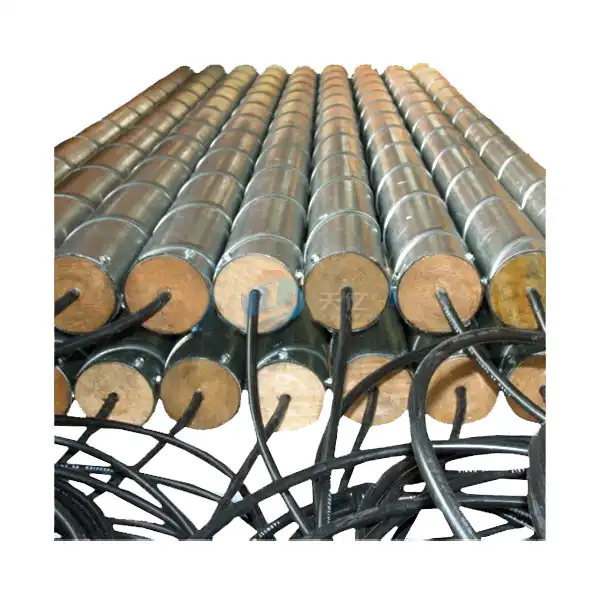

Material Selection

The process starts with the careful selection of high-grade titanium as the substrate material, chosen for its exceptional strength, corrosion resistance, and lightweight properties. The substrate is critical for the longevity and effectiveness of the ICCP (Impressed Current Cathodic Protection) system.

Design Engineering

Detailed design specifications are created for the canister anode, including its dimensions, shape, and performance requirements. This design is tailored to fit specific ICCP applications, ensuring optimal performance in various environments.

Substrate Preparation

The titanium substrates are cut and shaped to the required specifications using precise machining techniques, such as water jet cutting or CNC machining. The preparation ensures a uniform size and shape for all anodes.

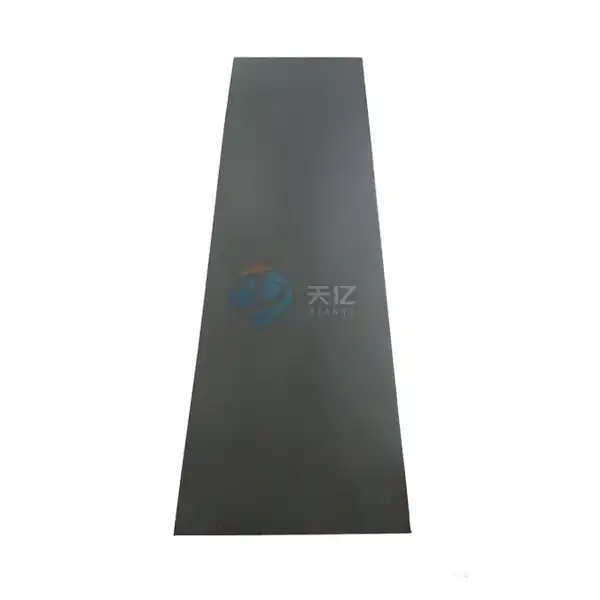

Surface Treatment

To enhance the bonding of the MMO coating, the titanium surfaces undergo a rigorous cleaning and roughening process. Methods such as grit blasting or chemical etching are employed to create a textured surface, improving the adhesion of the coating.

MMO Coating Application

The MMO (Mixed Metal Oxide) coating is applied using an electrochemical deposition process. The titanium canisters are immersed in a specially formulated bath containing mixed metal oxides like iridium and tantalum, ensuring a uniform and robust coating is applied to the substrate.

Curing and Drying

After the application of the MMO coating, the anodes are subjected to a curing process. This involves heating the canisters to specific temperatures to enhance the coating's adhesion and durability, ensuring optimal performance in corrosive environments.

Quality Control Checks

Throughout the production process, stringent quality control measures are implemented. Each batch of canister anodes undergoes tests for coating thickness, adhesion, and overall structural integrity to ensure compliance with industry standards.

Final Inspection

A comprehensive final inspection is performed to assess the quality of each anode. Any defects or inconsistencies are identified and rectified before proceeding to the packaging stage.

Packaging

The completed ICCP MMO canister anodes are carefully packaged using protective materials to prevent any damage during transportation. Clear labeling provides essential information regarding the product specifications and handling instructions.

Documentation

Each shipment includes thorough documentation detailing the product specifications, installation guidelines, and maintenance recommendations. This information helps customers ensure effective usage of the canister anodes in their cathodic protection systems.

Shipping Logistics

The packaged anodes are dispatched using reliable logistics partners. Tracking systems are utilized to ensure timely delivery, allowing customers to monitor the shipment's progress.

Post-Delivery Support

Once the anodes are delivered, customers have access to technical support for installation and maintenance inquiries. This support is vital for optimizing the performance of the ICCP system in which the canister anodes are utilized.

By adhering to this comprehensive production process, ICCP MMO canister anodes are engineered to provide reliable and efficient cathodic protection, significantly extending the lifespan of structures exposed to corrosive environments.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Every ICCP MMO Canister Anode undergoes comprehensive testing, including:

- Material Analysis: Verifying the integrity of raw materials.

- Performance Testing: Evaluating anode performance under various operational conditions.

- Final Inspection: Ensuring adherence to industry standards before shipment.

Packaging Method

Our packaging solutions are designed to protect the anodes during transit, featuring:

- Custom Packaging: Tailored to the dimensions of each order to minimize movement and damage.

- Eco-Friendly Materials: Utilizing sustainable packaging options to reduce environmental impact.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services to tailor our ICCP MMO Canister Anodes to your specific needs. From customized dimensions to unique coating formulations, we work closely with our partners to deliver solutions that meet exact requirements. We invest in quality packaging materials, such as robust boxes and cushioning materials like bubble wrap or foam inserts, to ensure a snug fit and prevent movement during shipping .

FAQ

Q: What is the expected lifespan of the product?

A: Our canister anodes have an expected service life of over 20 years, depending on environmental conditions and operational parameters.

Q: Can I customize the specifications?

A: Yes, we provide customizable solutions to fit your project requirements.

Q: How do I install the canister anode?

A: Installation guidelines will be provided with your order, ensuring straightforward integration into your existing systems.

Q: What industries can benefit from using your anodes?

A: Our anodes are used across various industries, including oil and gas, marine, water treatment, and industrial applications.

Contact Us

For more information about the ICCP MMO Canister Anode and how it can enhance your corrosion protection efforts, please contact us at [info@di-nol.com]. Our dedicated team is ready to assist you with any inquiries or custom solutions you may need.

YOU MAY LIKE

VIEW MOREmmo coated titanium anodes for cathodic protection

VIEW MOREmmo coated titanium anodes for cathodic protection VIEW MOREiccp protected mmo coated titanium anodes

VIEW MOREiccp protected mmo coated titanium anodes VIEW MOREiccp mmo coated titanium anodes

VIEW MOREiccp mmo coated titanium anodes VIEW MOREPowered Water Heater Anode Rod

VIEW MOREPowered Water Heater Anode Rod VIEW MOREICCP MMO Ribbon Anodes

VIEW MOREICCP MMO Ribbon Anodes_1731573049210.webp) VIEW MOREICCP MMO Tubular Anode

VIEW MOREICCP MMO Tubular Anode VIEW MORETitanium Anode For Steel Plate Galvanizing

VIEW MORETitanium Anode For Steel Plate Galvanizing_1731642084407.webp) VIEW MOREchlorine electrolyzer

VIEW MOREchlorine electrolyzer

_1731225283658.webp)

_1731225283595.webp)

_1731225283434.webp)