iccp protected mmo coated titanium anodes

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Product Introduction

Welcome to the world of ICCP protected MMO coated titanium anodes, a cutting-edge solution designed for various electrochemical applications. At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we specialize in producing high-performance MMO coated titanium anodes that ensure durability, efficiency, and reliability. Our ICCP (Impressed Current Cathodic Protection) protected anodes are engineered to withstand harsh environments, making them an essential component for industries such as water treatment, mining, electroplating, and more.

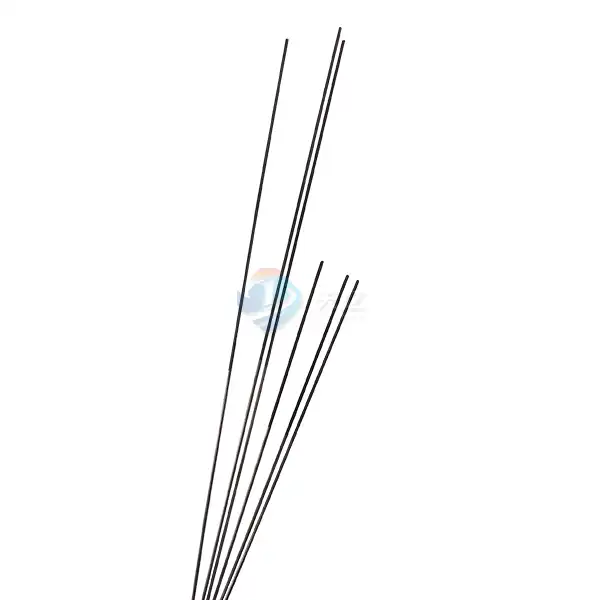

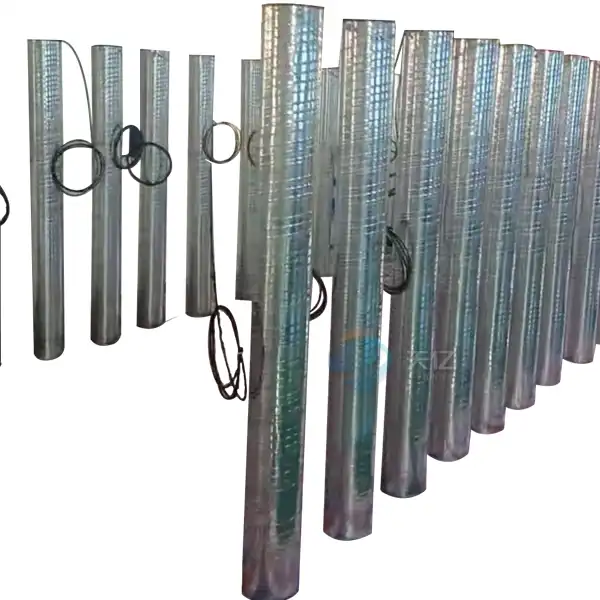

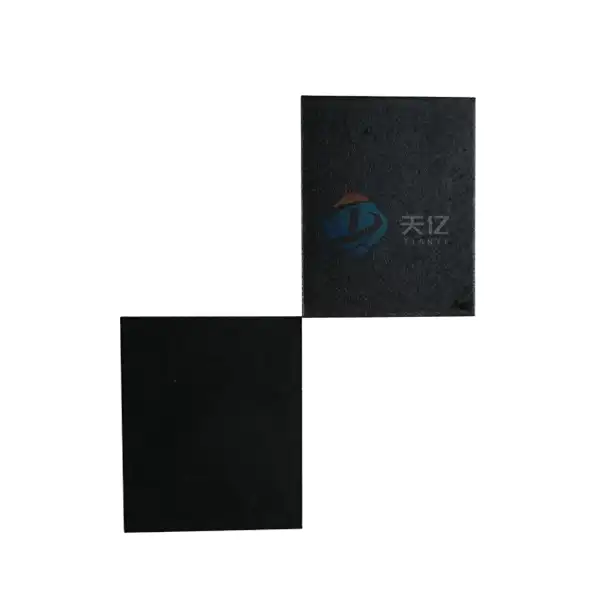

Product Show

|  |  |

|  |  |

Product Composition and Design

Our ICCP protected MMO coated titanium anodes are constructed using high-grade titanium substrates, ensuring exceptional strength and corrosion resistance. The anodes are coated with a mixed metal oxide, which significantly enhances their performance and longevity. This combination of materials and design ensures that our anodes maintain their effectiveness even in the most demanding environments.

Product Advantages

- Long Lifespan: Designed for extended service, our anodes exceed 10 years of operational life.

- High Efficiency: The mixed metal oxide coating optimizes electrochemical reactions, improving performance.

- Corrosion Resistance: The robust materials used protect against corrosion, ensuring reliable operation.

- Customizable Solutions: Tailored sizes and specifications to meet specific client requirements.

Technical Features

- Innovative Coating Technology: Our advanced coating techniques provide uniform coverage, enhancing performance and longevity.

- Robust Construction: Engineered to withstand high operational demands, making them ideal for various industrial applications.

- Sustainable Design: Focused on eco-friendly technologies, our anodes contribute to sustainable practices in electrochemical applications.

Product Application

ICCP protected MMO coated titanium anodes are widely utilized in:

1. Marine industry

2. Oil and gas industry

3. Construction and infrastructure

4. Utilities and water treatment

5. Energy sector

6. Public infrastructure development

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

The production begins with sourcing high-grade titanium, recognized for its remarkable resistance to corrosion and strength. This titanium substrate forms the foundation for the MMO (Mixed Metal Oxide) coating, which enhances the anode's performance in challenging environments.

Design Engineering

Engineers develop comprehensive design specifications that define the dimensions, surface area, and coating requirements for ICCP (Impressed Current Cathodic Protection) applications. This step ensures that the anodes are tailored for specific operational conditions.

Titanium Substrate Preparation

The titanium is precisely cut into predetermined shapes using techniques like water jet cutting or CNC machining, ensuring that each anode meets exact specifications for effective installation and functionality.

Surface Treatment

The next step involves preparing the titanium surfaces for coating. This is achieved through cleaning and surface roughening processes, such as abrasive blasting or chemical cleaning, which improve the adhesion of the subsequent coating.

MMO Coating Application

The MMO coating is applied using electrochemical deposition methods. The titanium substrates are immersed in a solution containing mixed metal oxides, which include elements like iridium and ruthenium, ensuring a uniform and durable coating that enhances the anode's electrochemical properties.

Curing Process

Once the coating is applied, the anodes undergo a curing process at specified temperatures to promote optimal adhesion and enhance the durability of the MMO coating. This step is critical for ensuring long-term performance.

ICCP Protection Integration

After curing, an integrated ICCP system is installed, which includes an external power supply and a control unit. This system applies an impressed current to the anodes, enhancing their protective capabilities in applications such as marine and underground structures.

Quality Assurance

Each anode undergoes rigorous quality control assessments, including coating thickness measurements, adhesion tests, and structural integrity evaluations. This ensures compliance with industry standards and specific project requirements.

Final Inspection

A comprehensive final inspection is performed to confirm the quality and functionality of the coated anodes. Any discrepancies are addressed before the products proceed to packaging.

Packaging

The finished ICCP protected MMO coated titanium anodes are carefully packaged to prevent damage during transport. Each package is labeled with vital information regarding product specifications and handling guidelines.

Documentation

Accompanying each shipment is detailed documentation that includes installation instructions, maintenance guidelines, and product specifications to facilitate effective use by customers.

Shipping

Finally, the packaged anodes are shipped using reliable logistics services. Shipment tracking ensures timely delivery, allowing customers to efficiently plan their installations.

Through this comprehensive production process, ICCP protected MMO coated titanium anodes are engineered to deliver superior performance, making them ideal for various applications requiring robust cathodic protection.

Quality Inspection

Quality is at the forefront of our operations. Each batch of ICCP protected MMO coated titanium anodes undergoes rigorous testing to ensure compliance with the highest standards. This includes:

- Raw material inspection

- Coating quality checks

- Performance testing under operational conditions

Packaging Method

Our packaging solutions are designed for safety and efficiency. Each product is carefully packed to prevent damage during transit, ensuring that they reach our clients in perfect condition. We offer various packaging options, including custom solutions to meet specific client requirements.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We are proud to offer comprehensive OEM services, allowing clients to customize their anodes to fit unique project specifications. Our expert team collaborates closely with clients to ensure that every product meets their needs perfectly.

FAQ

Q1: What are ICCP protected MMO coated titanium anodes?

A1: These are advanced electrochemical anodes designed for cathodic protection and other industrial applications, utilizing mixed metal oxide coatings for enhanced performance.

Q2: How long do these anodes last?

A2: Our anodes typically have a service life of over 10 years, depending on the application and environmental conditions.

Q3: Can I get customized sizes?

A3: Yes, we offer fully customizable solutions to meet specific client requirements.

Q4: What industries can benefit from these anodes?

A4: Industries such as water treatment, mining, electroplating, and more can benefit from our products.

Q5: How do I order?

A5: Please contact us directly at info@di-nol.com for inquiries and orders.

Contact Us

Ready to enhance your electrochemical processes with our products? Contact us today at [info@di-nol.com] for more information and tailored solutions. Let Shaanxi Tianyi be your trusted partner in cutting-edge electrochemical technology!

YOU MAY LIKE

VIEW MOREmmo coated titanium anodes for cathodic protection

VIEW MOREmmo coated titanium anodes for cathodic protection VIEW MOREiccp mmo coated titanium anodes

VIEW MOREiccp mmo coated titanium anodes VIEW MOREPowered Water Heater Anode Rod

VIEW MOREPowered Water Heater Anode Rod VIEW MOREICCP MMO Ribbon Anodes

VIEW MOREICCP MMO Ribbon Anodes_1731573049210.webp) VIEW MOREICCP MMO Tubular Anode

VIEW MOREICCP MMO Tubular Anode VIEW MOREICCP MMO Canister Anode

VIEW MOREICCP MMO Canister Anode_1731642449066.webp) VIEW MOREAcidic oxidation potential water generator

VIEW MOREAcidic oxidation potential water generator VIEW MORETitanium Mesh Anode For Water Treatment

VIEW MORETitanium Mesh Anode For Water Treatment