Titanium Mesh Anode For Water Treatment

High electrocatalytic activity

Long and stable life

Reduced energy consumption costs

Reduced use of chemical agents

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd.! We are excited to introduce our Titanium Mesh Anode for Water Treatment, a cutting-edge solution designed to enhance water purification and disinfection processes. Our titanium mesh anodes are crafted using high-performance MMO (Mixed Metal Oxide) coatings, ensuring superior durability and corrosion resistance, making them an ideal choice for various industrial applications.

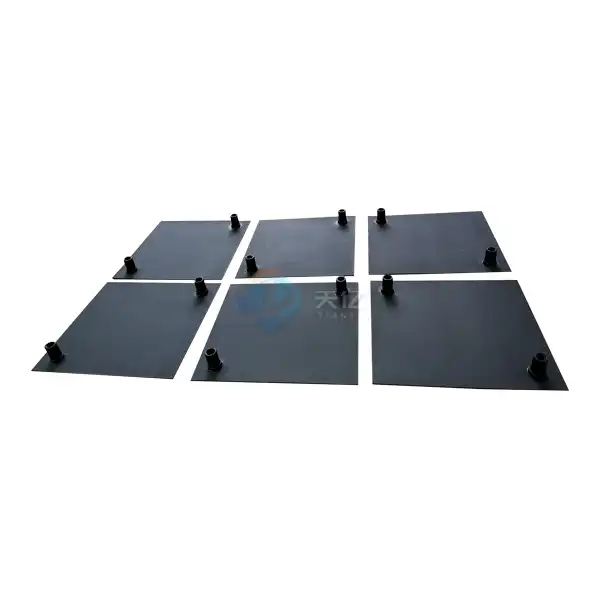

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

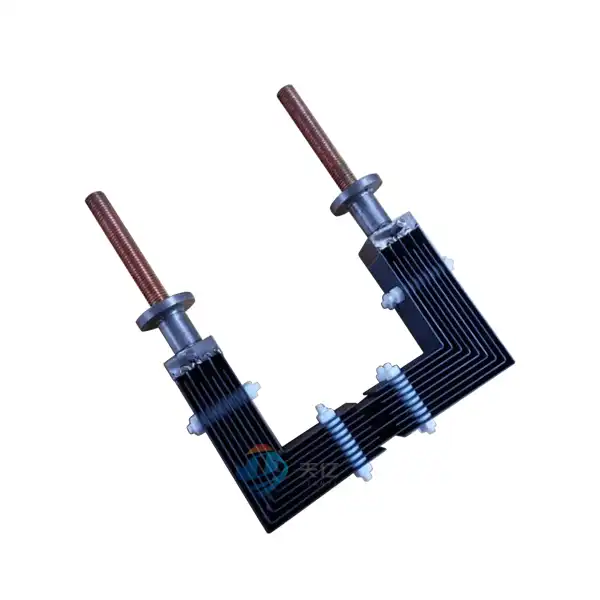

Product Composition and Design

Our Titanium Mesh Anode for Water Treatment feature a unique design that maximizes surface area for electrochemical reactions while minimizing material usage. This innovative approach not only reduces production costs but also enhances the overall efficiency of the anode in water treatment applications. The anodes are meticulously manufactured to meet stringent quality standards, ensuring consistent performance.

Product Advantages

- Durability: Our titanium mesh anodes are built to last, providing long-term solutions for water treatment.

- Corrosion Resistance: The MMO coating ensures exceptional resistance to corrosive environments, extending the lifespan of the anode.

- High Efficiency: Designed for optimal performance, our anodes deliver effective electrochemical reactions for efficient water purification.

- Customization: We offer tailored solutions to meet specific client requirements, ensuring the right fit for various applications.

Technical Features

- Electrochemical Performance: High current efficiency, promoting faster electrolysis.

- Versatile Applications: Suitable for disinfection, wastewater treatment, and industrial processes.

- Eco-Friendly: Contributes to sustainable water treatment solutions by reducing harmful byproducts.

Product Application

Our Titanium Mesh Anodes are widely used in:

Municipal and Community Water Purification: MMO anodes are used to enhance water quality and safety in public water systems, effectively removing contaminants and supporting reliable water supplies.

Treatment of Cooling Systems: In industrial cooling water systems, MMO anodes prevent biofouling and corrosion, maintaining system efficiency and extending the lifespan of cooling equipment.

Swimming Pool and Spa Sanitation: MMO anodes help in disinfecting swimming pools and spas by generating necessary sanitizing agents, promoting clean and safe recreational water.

Marine Wastewater Management: Marine vessels and coastal facilities use MMO anodes to treat wastewater, ensuring environmental compliance and protecting marine ecosystems.

Sodium Hypochlorite Generation: MMO anodes facilitate the production of sodium hypochlorite, a widely-used disinfectant, through the electrochemical process, benefiting applications in sanitation and disinfection.

Cathodic Protection: MMO anodes are applied in cathodic protection systems to prevent corrosion in pipelines, storage tanks, and marine structures, helping to safeguard these assets from environmental damage.

Wastewater Treatment for Municipal Sewage: In sewage treatment plants, MMO anodes play a key role in breaking down pollutants, contributing to cleaner discharge and environmental sustainability.

Hospital Wastewater Processing: MMO anodes aid in the treatment of hospital wastewater, effectively reducing contaminants and ensuring safe water discharge that meets health standards.

Dye Industry Wastewater Treatment: Used in treating wastewater from dyeing processes, MMO anodes help in breaking down complex dye molecules, resulting in cleaner industrial discharge.

Industrial Cooling Water Maintenance: MMO anodes support industrial cooling water systems by reducing corrosion and scaling, preserving equipment and ensuring efficient system operation.

Electroplating Effluent Treatment: MMO anodes are essential in treating wastewater from electroplating processes, removing heavy metals and other contaminants to protect the environment.

Electro-Chlorination of Brine Water: In electro-chlorination systems, MMO anodes convert brine into chlorinated water, useful for disinfection in various applications, including water treatment and sanitation.

Desalination of Seawater: MMO anodes are used in seawater desalination plants to improve efficiency in salt removal processes, supporting the production of potable water from seawater sources.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

We employ a rigorous production process that includes:

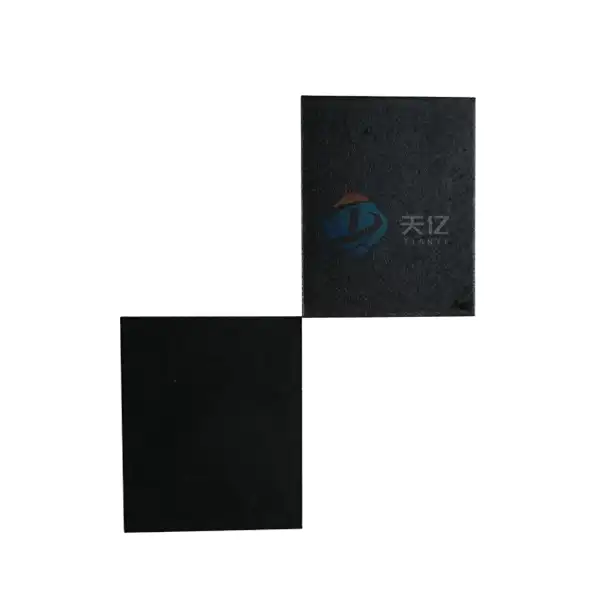

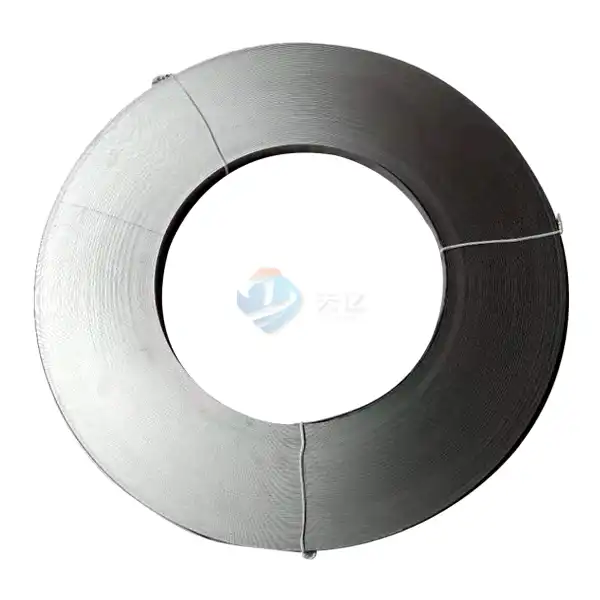

Material Selection

Choose high-grade titanium, typically Grade 2 or 5, known for its excellent corrosion resistance and mechanical properties. This selection ensures durability and effectiveness in water treatment applications.

Mesh Design and Engineering

Develop detailed specifications for the mesh, including dimensions, mesh opening size, and thickness. The design should facilitate optimal flow of water and enhance electrochemical reactions during treatment.

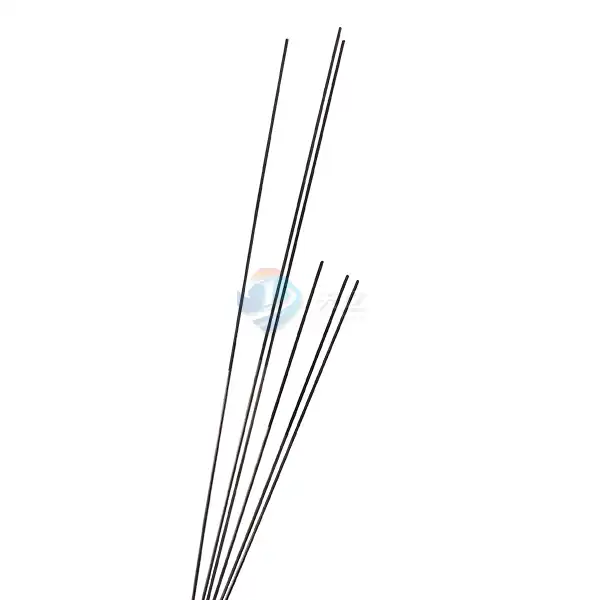

Wire Preparation

Cut titanium wires to the required lengths based on the mesh design. Utilize precision cutting techniques to ensure uniformity and accuracy, which are critical for achieving the desired mesh configuration.

Weaving Process

Employ a weaving method to create the titanium mesh structure. Techniques such as plain weave or twill weave can be used, depending on the application requirements. Ensure that the mesh is tight enough to maintain structural integrity while allowing water to pass through efficiently.

Surface Preparation

Clean the woven titanium mesh thoroughly to remove any contaminants or oxidation. This is typically achieved through a combination of chemical cleaning agents and mechanical polishing to create a clean and reactive surface.

Coating Application

Apply a conductive coating to the titanium mesh to enhance its electrochemical performance. Common coatings include mixed metal oxides (MMO) or platinum, which improve the anode’s efficiency and longevity in water treatment processes.

Curing Process

Cure the coated mesh anode in a controlled environment. This process may involve heating at specified temperatures to ensure proper adhesion of the coating and to optimize its electrochemical characteristics.

Quality Control Inspection

Implement stringent quality control measures to inspect the mesh for defects, uniformity, and coating adherence. Use methods such as visual inspections, coating thickness measurements, and adhesion tests to ensure high-quality production.

Electrochemical Testing

Perform electrochemical performance testing in simulated water treatment conditions. Evaluate parameters such as current efficiency, chlorine generation capacity, and operational stability to ensure the anode meets industry standards.

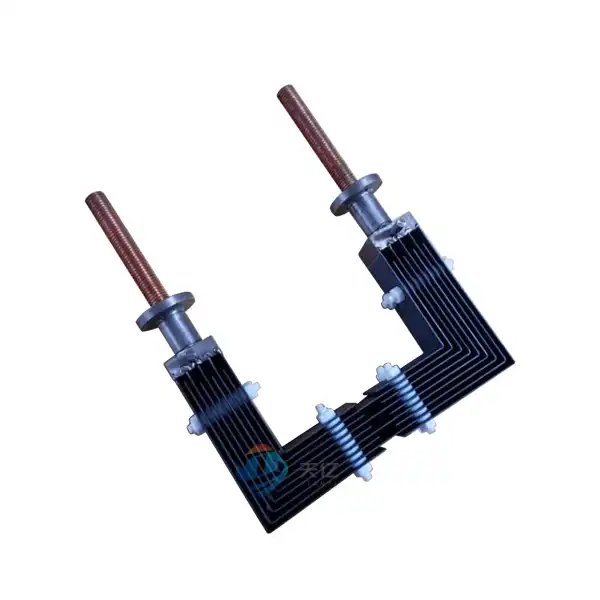

Final Assembly and Packaging

Assemble the titanium mesh anodes with any required fittings or supports for easy installation in water treatment systems. Package the finished anodes securely to prevent damage during transit, accompanied by product documentation that includes specifications and testing results.

By adhering to this meticulous production process, manufacturers can produce high-quality titanium mesh anodes tailored for effective water treatment applications, ensuring reliability and efficiency in electrochemical processes.

Quality Inspection

Quality is our top priority. Each Titanium Mesh Anode for Water Treatment undergoes extensive testing for:

- Corrosion resistance

- Dimensional accuracy

- Electrochemical performance

This meticulous quality assurance process guarantees that our products exceed industry benchmarks.

Packaging Method

We prioritize safe and efficient packaging to ensure our products reach you in perfect condition. Our packaging solutions include:

- Custom foam inserts

- Durable cardboard boxes

- Eco-friendly materials

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we take pride in offering comprehensive OEM services that empower our clients to fully customize their Titanium Mesh Anode for Water Treatment according to their unique specifications and requirements. Our dedicated team collaborates closely with you throughout the development process, leveraging our expertise to create tailored solutions that not only meet your specific needs but also ensure optimal performance and longevity of the anodes in their intended applications. Whether you require specialized dimensions, configurations, or material properties, we are committed to delivering high-quality products that exceed your expectations.

FAQ

1. What is the lifespan of the Titanium Mesh Anode?

Our anodes typically last over 5 years, depending on application conditions.

2. Can you customize the size of the anodes?

Yes, we offer customizable dimensions to fit your specific needs.

3. What industries can benefit from your anodes?

Our products are used in water treatment, electroplating, mining, and many other sectors.

4. How do you ensure the quality of your products?

We follow strict quality control measures throughout the production process, from raw material selection to final testing.

5. What are your shipping options?

We work with reliable logistics partners to ensure timely and secure worldwide deliveries.

Contact Us

For more information about our Titanium Mesh Anode for Water Treatment or to discuss your specific requirements, please contact us at info@di-nol.com. We look forward to helping you achieve your water treatment goals with our advanced electrochemical solutions!

_1731396613400.webp)