Titanium Anode For Electrodialysis

High electrocatalytic activity

Long and stable life

Reduced energy consumption costs

Reduced use of chemical agents

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. Our Titanium Anode for Electrodialysis is designed to deliver outstanding performance in a variety of electrochemical applications. Crafted from high-quality titanium alloys and advanced coatings, these anodes are integral to improving the efficiency and sustainability of electrochemical processes, particularly in water treatment and ion exchange systems.

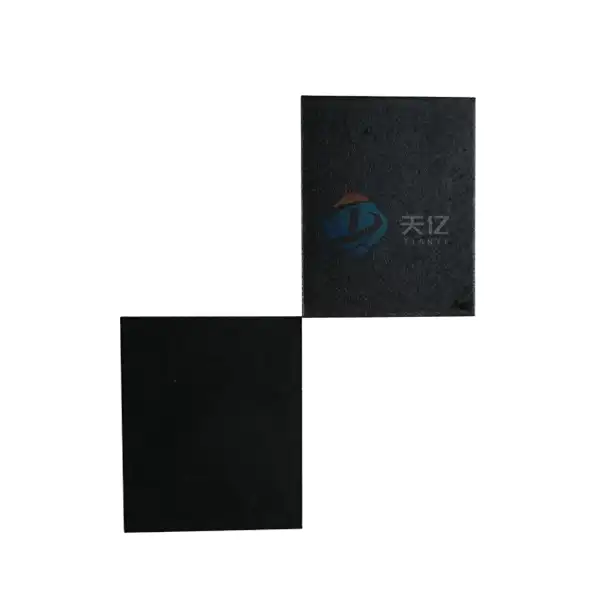

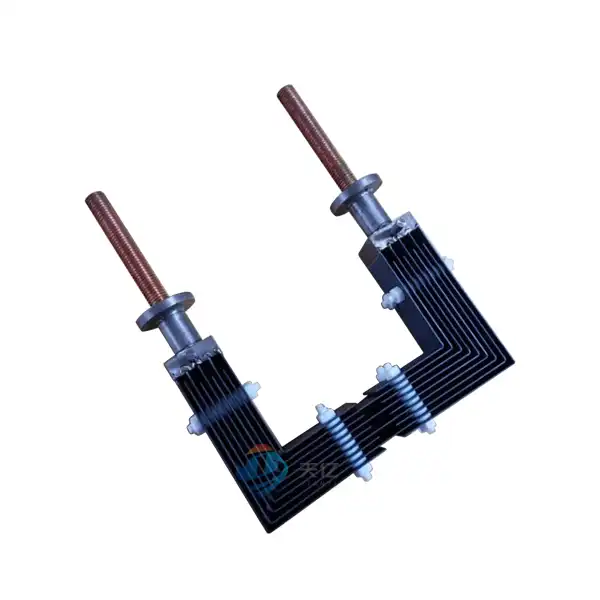

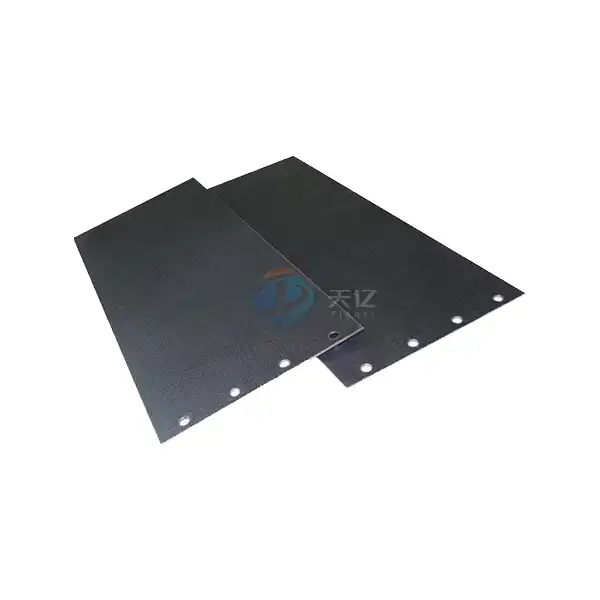

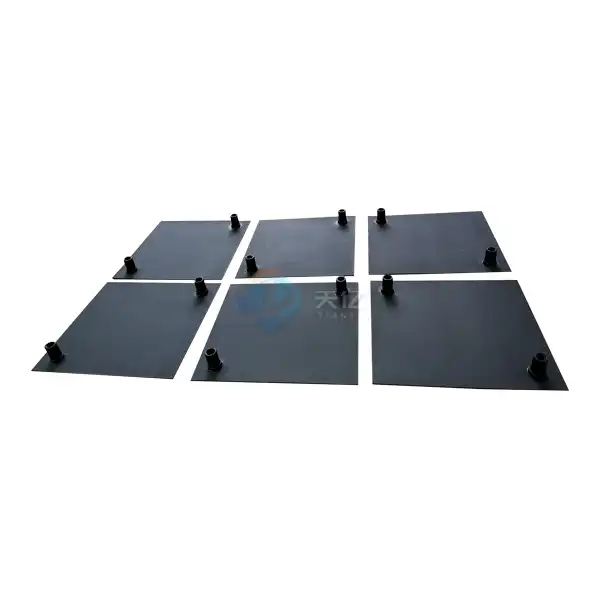

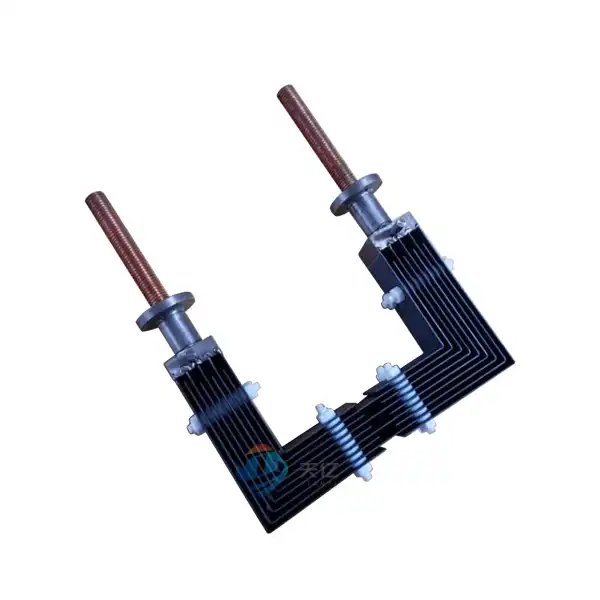

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

Product Composition and Design

Our Titanium Anode for Electrodialysis boasts a robust construction, featuring a Metal Matrix Oxide (MMO) coating that significantly enhances both corrosion resistance and electrical conductivity. This advanced design ensures optimal durability and longevity, even in challenging environments.

Engineered to facilitate efficient ion transport, our anodes promote superior electrolysis performance, resulting in increased efficiency and reduced energy consumption during the electrodialysis process. The innovative MMO coating not only improves the anode's performance but also minimizes maintenance requirements, allowing for uninterrupted operation and maximizing productivity.

We understand that different applications have unique requirements, which is why we offer custom dimensions and designs tailored to meet specific customer needs. Whether for industrial-scale operations or specialized research applications, our team collaborates closely with clients to deliver solutions that align perfectly with their operational goals.

In addition, our Titanium Anodes are rigorously tested to ensure they meet the highest industry standards. By choosing our anodes, customers can expect enhanced performance, reduced downtime, and a significant return on investment. Let us partner with you to elevate your electrodialysis processes with our state-of-the-art Titanium Anodes.

Product Advantages

- High Corrosion Resistance: Engineered for durability, our titanium anodes resist degradation in harsh electrochemical environments.

- Enhanced Efficiency: The advanced coating allows for higher current densities, leading to improved electrolysis rates.

- Long Lifespan: Designed for longevity, our anodes provide consistent performance for over a decade, minimizing replacement costs.

- Customizable Solutions: Tailored dimensions and coatings are available, ensuring optimal fit for any application.

Technical Features

- High Performance: Optimal for a variety of electrochemical processes including desalination and water purification.

- Low Energy Consumption: Designed to maximize efficiency, reducing operational costs.

- Eco-Friendly: Contributes to sustainable practices by enhancing the efficiency of water treatment systems.

Product Application

Our Titanium Anode for Electrodialysis is widely used in:

Municipal and Community Water Purification: MMO anodes are used to enhance water quality and safety in public water systems, effectively removing contaminants and supporting reliable water supplies.

Treatment of Cooling Systems: In industrial cooling water systems, MMO anodes prevent biofouling and corrosion, maintaining system efficiency and extending the lifespan of cooling equipment.

Swimming Pool and Spa Sanitation: MMO anodes help in disinfecting swimming pools and spas by generating necessary sanitizing agents, promoting clean and safe recreational water.

Marine Wastewater Management: Marine vessels and coastal facilities use MMO anodes to treat wastewater, ensuring environmental compliance and protecting marine ecosystems.

Sodium Hypochlorite Generation: MMO anodes facilitate the production of sodium hypochlorite, a widely-used disinfectant, through the electrochemical process, benefiting applications in sanitation and disinfection.

Cathodic Protection: MMO anodes are applied in cathodic protection systems to prevent corrosion in pipelines, storage tanks, and marine structures, helping to safeguard these assets from environmental damage.

Wastewater Treatment for Municipal Sewage: In sewage treatment plants, MMO anodes play a key role in breaking down pollutants, contributing to cleaner discharge and environmental sustainability.

Hospital Wastewater Processing: MMO anodes aid in the treatment of hospital wastewater, effectively reducing contaminants and ensuring safe water discharge that meets health standards.

Dye Industry Wastewater Treatment: Used in treating wastewater from dyeing processes, MMO anodes help in breaking down complex dye molecules, resulting in cleaner industrial discharge.

Industrial Cooling Water Maintenance: MMO anodes support industrial cooling water systems by reducing corrosion and scaling, preserving equipment and ensuring efficient system operation.

Electroplating Effluent Treatment: MMO anodes are essential in treating wastewater from electroplating processes, removing heavy metals and other contaminants to protect the environment.

Electro-Chlorination of Brine Water: In electro-chlorination systems, MMO anodes convert brine into chlorinated water, useful for disinfection in various applications, including water treatment and sanitation.

Desalination of Seawater: MMO anodes are used in seawater desalination plants to improve efficiency in salt removal processes, supporting the production of potable water from seawater sources.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our manufacturing process follows stringent quality control standards:

Raw Material Selection

Select high-grade titanium, typically Grade 1 or Grade 2, which offers excellent corrosion resistance, strength, and compatibility with the electrochemical environment of electrodialysis applications.

Design Specifications

Create detailed design specifications for the anode, considering factors such as surface area, thickness, and overall dimensions. Ensure the design facilitates optimal ion exchange and minimizes resistance during operation.

Cutting and Shaping

Use precision cutting techniques (such as laser cutting or water jet cutting) to shape the titanium plates into the desired form. Maintain tight tolerances to ensure consistency and functionality within the electrodialysis cell.

Surface Treatment

Conduct thorough cleaning and surface preparation, including degreasing and mechanical polishing. This enhances the adhesion of coatings and improves electrochemical properties by increasing surface area.

Coating Application

Apply a specialized electro-catalytic coating to the titanium surface to improve its electrochemical activity. Common choices include mixed metal oxides (MMOs) or noble metal coatings, which enhance the anode's efficiency in ion transport and oxidation processes.

Curing

Cure the coated anode at specified temperatures to promote optimal adhesion and performance of the coating. This step ensures that the anode maintains its electrochemical properties under operational conditions.

Quality Control Testing

Implement rigorous quality control measures, testing the anode for dimensional accuracy, coating adhesion, and corrosion resistance. Verify that each anode meets established performance standards.

Electrochemical Evaluation

Conduct electrochemical testing to assess the anode's performance under simulated operating conditions. Evaluate parameters such as current efficiency, overpotential, and stability over time.

Assembly for Integration

Prepare the anode for installation in the electrodialysis system, ensuring that it includes necessary connectors and supports. Verify compatibility with other system components.

Packaging and Documentation

Package the finished titanium anodes carefully to prevent damage during transport. Include detailed documentation that outlines technical specifications, performance data, and installation instructions for end-users.

By following this comprehensive production process, manufacturers can ensure that titanium anodes for electrodialysis are produced to the highest standards, optimizing their performance in ion separation and water treatment applications.

Quality Inspection

Quality is our priority. Each Titanium Anode is subjected to:

- Visual Inspection: Checking for any physical defects.

- Performance Testing: Evaluating corrosion resistance and electrochemical efficiency.

- Dimension Verification: Ensuring all specifications are met accurately.

Packaging Method

To ensure safe delivery, our anodes are packaged using:

- Custom foam inserts for protection

- Weather-resistant packaging

- Clear labeling for easy identification

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We proudly offer OEM services, allowing clients to customize products according to their specific requirements. Whether it’s unique dimensions or tailored coating solutions, we can provide exactly what you need.

FAQ

Q: What is the lifespan of the Titanium Anode for Electrodialysis?

A: Our anodes can last over 10 years, depending on the application and operating conditions.

Q: Can I customize the dimensions of the anodes?

A: Yes, we offer fully customizable solutions to meet your specific requirements.

Q: What industries can benefit from your titanium anodes?

A: Our anodes are widely used in water treatment, electroplating, and other electrochemical applications.

Q: How can I ensure the right anode for my application?

A: Our expert team is available to assist you in selecting the best product based on your operational needs.

Contact Us

For more information or to discuss your specific requirements, please reach out to us at [info@di-nol.com]. We’re here to help you find the perfect solution for your electrochemical needs!

YOU MAY LIKE

VIEW MOREPlatinum-titanium anode

VIEW MOREPlatinum-titanium anode VIEW MOREIr-Ta oxide coated DSA electrode

VIEW MOREIr-Ta oxide coated DSA electrode VIEW MOREMMO/Ti Linear Anode

VIEW MOREMMO/Ti Linear Anode VIEW MOREtitanium electrodes for salt chlorinator

VIEW MOREtitanium electrodes for salt chlorinator VIEW MOREtitanium electrodes for salt water electrolysis

VIEW MOREtitanium electrodes for salt water electrolysis_1731396613400.webp) VIEW MOREElectrode for electro-oxidation waste water treatment

VIEW MOREElectrode for electro-oxidation waste water treatment VIEW MORETitanium Mesh Anode For Water Treatment

VIEW MORETitanium Mesh Anode For Water Treatment