MMO/Ti Linear Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

MMO/Ti Linear Anode Introduction

TianYI's MMO/Ti Linear Anode stands out for its exceptional durability and efficiency. Designed for various industrial applications, our anodes ensure consistent performance and extended lifespan, making them the preferred choice for professionals in the electrochemical, electroplating, corrosion protection, and environmental industries.

Product Specifications

Product Model | ELTA-15 (MMO coated φ1.5mm titanium wire anode) | ELTA-30 (MMO coated φ3.0mm anode wire) |

Outer diameter of combined flexible anode | 38 | 38 |

MMO/Ti anode core diameter | 1.5mm | 3.0mm |

Output Current | 300~1000mAm | 300~1000mAm |

Design life | ≥40 years, can be designed according to user requirements | ≥40 years, can be designed according to user requirements |

cable | 1×10mm2XLPE/PVC | 1×10mm2XLPE/PVC |

Filling toner carbon content | ≥99.5% | ≥99.5% |

Contact resistance between MMO/Ti wire and cable | ≤0.0009Ω | ≤0.0009Ω |

Anode weight | 1.5Kg/m | 1.5Kg/m |

Length of anode per roll | 500m, 1000m (can be cut to length freely) | 500m, 1000m (can be cut to length freely) |

|  |  |

|  |  |

Product Composition and Design

The MMO/Ti Linear Anode is composed of a titanium substrate coated with a thin layer of mixed metal oxides. This innovative design enhances electrical conductivity and ensures longevity. The flexible design allows for various configurations, making it adaptable to specific industrial needs.

Product Advantages

- Durability: Our anodes are designed to withstand harsh environments, providing long service life.

- High Efficiency: Enhanced current efficiency reduces operational costs, making them ideal for large-scale applications.

- Eco-Friendly: We prioritize environmental responsibility, ensuring our products comply with eco-friendly standards.

Technical Features

- Advanced Coating Technology: The MMO coating enhances the anode's performance by improving corrosion resistance and increasing service life.

- Customizable Dimensions: We provide tailored solutions to meet specific requirements, ensuring compatibility with existing systems.

- Versatile Applications: Ideal for a variety of industries, including electroplating, cathodic protection, and water treatment.

MMO/Ti Linear Anode Application

The MMO/Ti Linear Anode is utilized in:

Electrochemical Industry: Used in processes like electrolysis of aluminum, copper, and zinc.

Electroplating: Ideal for metal surface treatment and plating processes.

Corrosion Protection: Essential for marine engineering, petrochemical, and power facilities.

Environmental Protection: Effective in wastewater treatment and electrochemical oxidation.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

The production of MMO/Ti Linear Anodes involves several meticulous steps to ensure high quality and performance:

Surface Preparation: The process begins with the thorough cleaning of commercially pure titanium substrates. This includes chemical etching and sometimes mechanical abrasion to ensure a clean and reactive surface for coating.

Coating Application: The cleaned titanium substrate is then coated with a mixed metal oxide (MMO) layer. This involves applying a liquid solution of metal salts, which is subsequently thermally decomposed at high temperatures (typically between 400 to 600°C) to form a uniform and adherent MMO layer.

Layering Process: Multiple layers of MMO coating are applied, with each layer being heat-treated before the next is added. This ensures a robust and durable coating that can withstand harsh operational environments.

Quality Control: Throughout the production process, rigorous quality control measures are implemented. Each batch of anodes undergoes comprehensive testing for coating thickness, adhesion, and overall performance to ensure they meet the required standards.

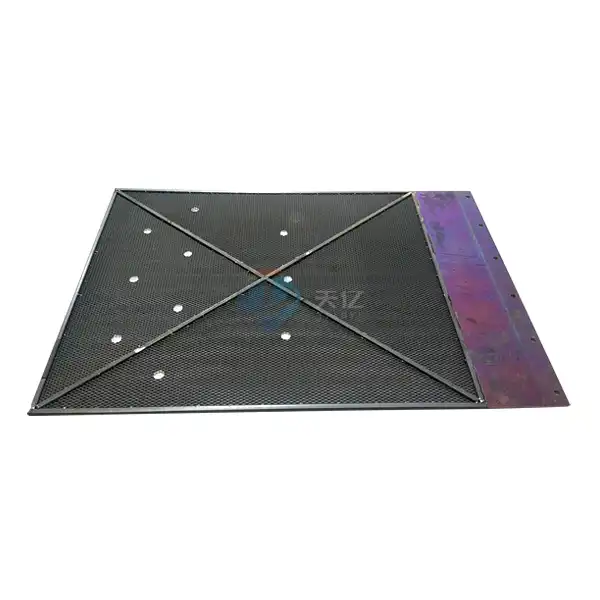

Final Assembly: The coated titanium anodes are then assembled with internal cables and filled with coke powder. The external fabrics and mechanically braided protective mesh are wrapped around the assembly to provide additional protection and durability.

Testing and Certification: The final product is tested for electrical performance, corrosion resistance, and mechanical integrity. Certifications such as ISO 9001 ensure that the anodes meet international quality standards.

Quality Inspection

We adhere to strict quality control measures throughout the production process. This includes:

- Raw Material Testing: Ensuring only the best materials are used.

- In-Process Inspections: Continuous monitoring during manufacturing.

- Final Product Testing: Comprehensive testing to meet industry standards.

Packaging Method

Our MMO/Ti Linear Anode packaging is designed to protect the anodes during transit. We use custom packaging solutions that ensure:

- Safety: Prevents damage during shipping.

- Cost-Effectiveness: Reduces shipping costs while maintaining product integrity.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we provide comprehensive OEM services tailored specifically to meet your unique needs. Our experienced team collaborates closely with clients to understand their specific requirements, ensuring that we develop customized solutions that align perfectly with their operational objectives. From initial concept and design to final production, we focus on delivering high-quality products that meet industry standards. Whether you require specialized materials, unique dimensions, or specific functionalities, our commitment to precision and excellence ensures that your vision is realized effectively. Trust us to be your dedicated partner in creating innovative products that enhance your business.

FAQ

Q: What industries use these?

A: They are used in water treatment, electroplating, and cathodic protection, among others.

Q: Can you customize the anodes for specific applications?

A: Yes, we provide tailored solutions based on your operational requirements.

Q: What is the expected lifespan of your anodes?

A: With proper maintenance, our anodes can last several years, depending on the application and operating conditions.

Contact Us

For more information about our MMO/Ti Linear Anode and to discuss your specific needs, please reach out to us at info@di-nol.com. Our dedicated team is ready to assist you in finding the best solutions for your electrochemical applications.

YOU MAY LIKE

VIEW MORETitanium Wire Anode

VIEW MORETitanium Wire Anode VIEW MOREFlexible Linear Anodes

VIEW MOREFlexible Linear Anodes VIEW MOREPolymer flexible anode

VIEW MOREPolymer flexible anode VIEW MORELead oxide electrode

VIEW MORELead oxide electrode VIEW MOREgrade 1 titanium electrode

VIEW MOREgrade 1 titanium electrode VIEW MOREtitanium electrode for electrolysis

VIEW MOREtitanium electrode for electrolysis_1731396613400.webp) VIEW MOREElectrode for electro-oxidation waste water treatment

VIEW MOREElectrode for electro-oxidation waste water treatment_1731642168251.webp) VIEW MOREtitanium electrolyzer for electro-chlorination

VIEW MOREtitanium electrolyzer for electro-chlorination