grade 1 titanium electrode

Effective overpotential

Reusable

Excellent current density and production capacity

Customizable geometry of oxide-coated titanium anodes

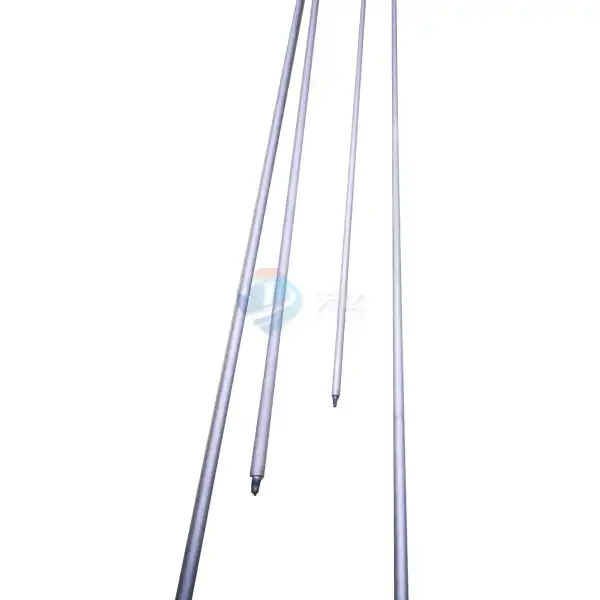

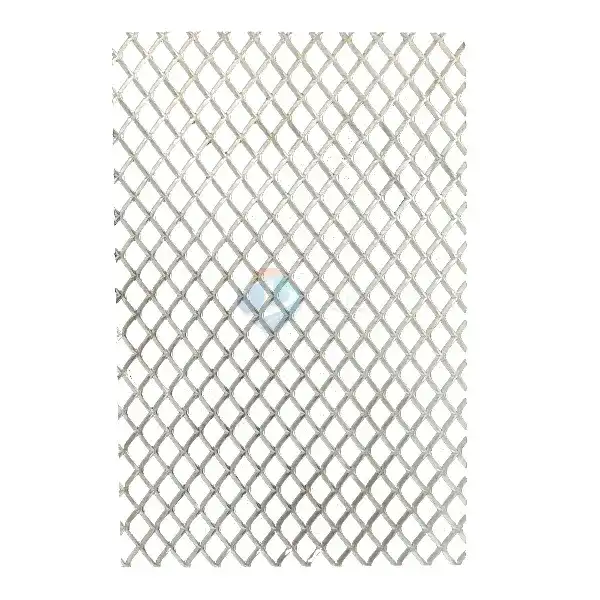

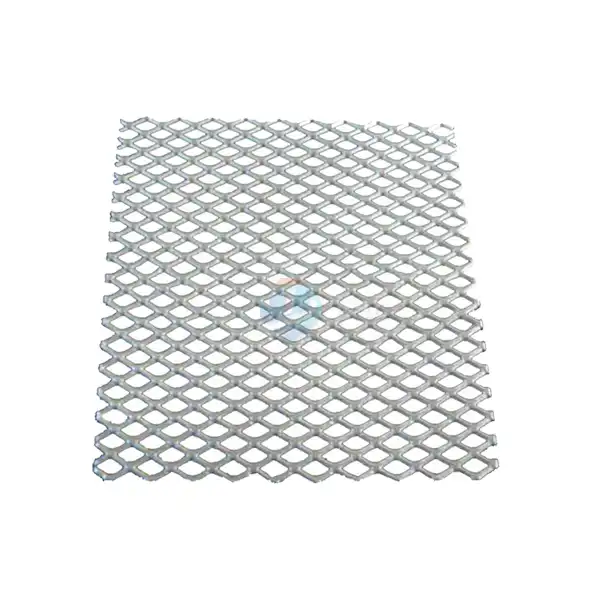

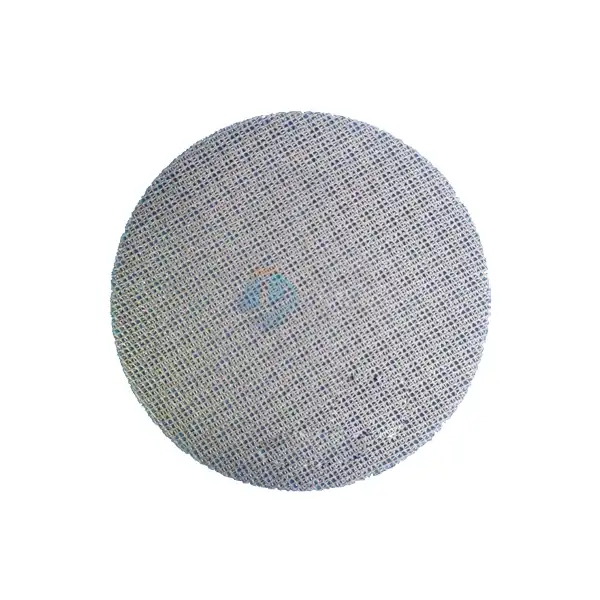

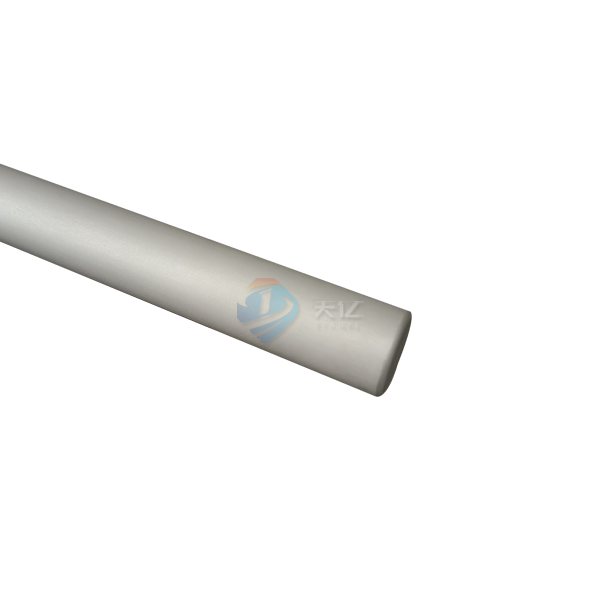

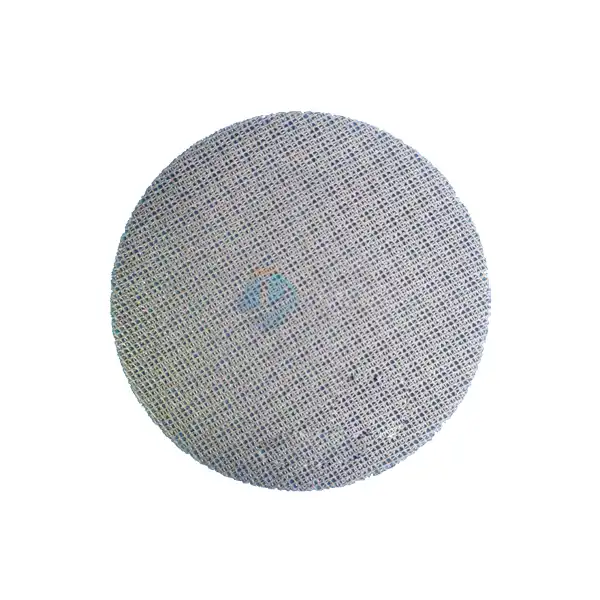

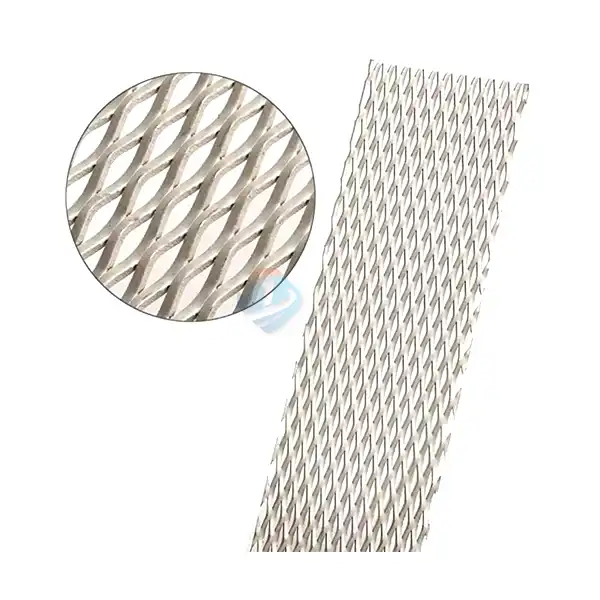

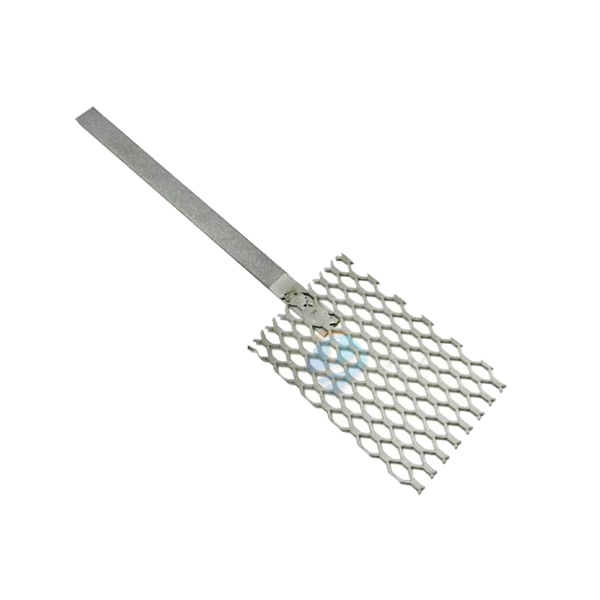

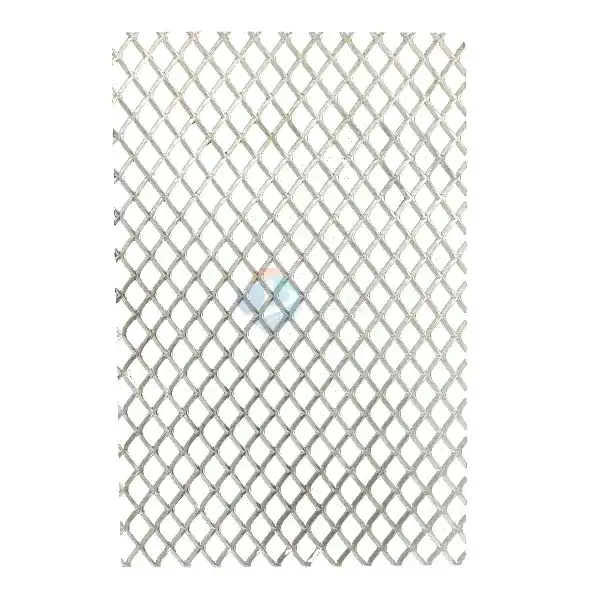

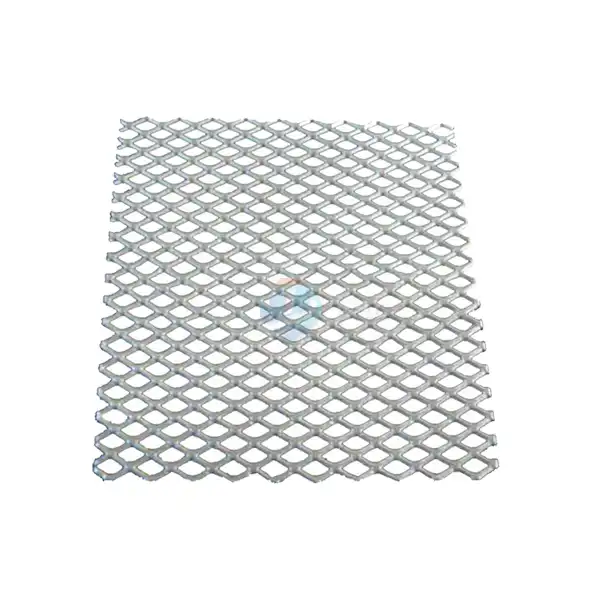

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Grade 1 Titanium Electrode Introduction

At TianYI, we pride ourselves on delivering high-quality Grade 1 Titanium Electrodes that meet the stringent demands of various industries. Our electrodes are designed to provide exceptional performance, durability, and reliability. Here’s why you should choose us:

Superior Quality: Made from pure Grade 1 titanium, ensuring excellent conductivity and corrosion resistance.

Consistent Performance: Rigorously tested to meet international standards, such as ASTM B338.

Custom Solutions: Tailored to your specific needs, whether for electrolysis, metal refining, or wastewater treatment.

Reliable Supply Chain: Stable and efficient logistics to ensure timely delivery.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

The Grade 1 Titanium Electrode is composed primarily of titanium (99.2% purity), ensuring excellent mechanical properties and resistance to corrosion. Its design can be customized to meet specific requirements, allowing for versatility in various applications. Whether you need a thin film or a thicker gauge, we can tailor the product to suit your needs. The development of MMO coatings involves innovative methods to ensure that the coating adheres well to the substrate and provides a stable, long-lasting surface for electrochemical reactions.

Product Advantages

- Corrosion Resistance: Grade 1 titanium exhibits outstanding resistance to corrosive environments, ensuring longevity and reliability.

- Lightweight: Its low density makes it easier to handle and install without compromising strength.

- Biocompatibility: Safe for use in medical applications due to its compatibility with biological tissues.

- Customizable Options: Tailored solutions to meet the specific demands of various industries.

Technical Features

- Excellent Conductivity: Grade 1 titanium provides efficient electrical conductivity, which enhances electrochemical reactions.

- Temperature Stability: Maintains performance across a wide temperature range, making it suitable for extreme conditions.

- Durability: Designed to withstand harsh environments, ensuring a long service life.

Product Application

The Grade 1 Titanium Electrode is widely used in:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process ensures the highest quality standards:

Raw Material Selection: We source high-purity titanium to ensure the best quality.

Melting and Casting: Advanced melting techniques are used to create uniform and defect-free electrodes.

Forming and Shaping: Electrodes are shaped to precise specifications using state-of-the-art machinery.

Quality Inspection: Rigorous testing is conducted to ensure all electrodes meet our stringent quality standards.

Packaging and Delivery: Products are carefully packaged to prevent damage during transportation.

Quality Inspection

Quality is our priority. Each Grade 1 Titanium Electrode undergoes thorough inspections, including:

- Raw Material Testing: Ensuring only the best materials are used.

- Dimensional Checks: Confirming compliance with specified measurements.

- Performance Testing: Evaluating corrosion resistance and conductivity.

Packaging Method

We use custom packaging solutions that prioritize safety and efficiency. Each electrode is securely packed to prevent damage during transit, ensuring that it arrives in optimal condition.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer OEM services tailored to your specifications. Whether you need unique dimensions, coatings, or packaging solutions, our team is here to help.

FAQ

Q: What is the difference between Grade 1 and other titanium grades?

A:Grade 1 Titanium Electrode is commercially pure, offering excellent corrosion resistance and biocompatibility, making it ideal for medical and electrochemical applications.

Q: Can I get custom sizes for the electrodes?

A: Yes! We provide customizable options for both length and diameter to meet your specific requirements.

Q: What industries benefit from using the products?

A: Industries such as water treatment, electroplating, and cathodic protection benefit greatly from our electrodes.

Q: How does your quality control process work?

A: We implement rigorous quality checks at every stage of production, from raw material sourcing to final product testing.

Contact Us

For more information on our ptoducts or to discuss your specific needs, please contact us at [info@di-nol.com]. We look forward to partnering with you for all your electrochemical material needs!

YOU MAY LIKE

VIEW MOREPlatinum-titanium anode

VIEW MOREPlatinum-titanium anode VIEW MOREPlatinum-titanium anode plate

VIEW MOREPlatinum-titanium anode plate VIEW MOREplatinum coated titanium anode

VIEW MOREplatinum coated titanium anode VIEW MOREPlatinum-coated titanium mesh anode

VIEW MOREPlatinum-coated titanium mesh anode VIEW MOREPlatinum-coated titanium electrode

VIEW MOREPlatinum-coated titanium electrode VIEW MOREelectroplating titanium electrode

VIEW MOREelectroplating titanium electrode VIEW MORETitanium Electrodes for Water Ionization

VIEW MORETitanium Electrodes for Water Ionization VIEW MOREtitanium electrode

VIEW MOREtitanium electrode