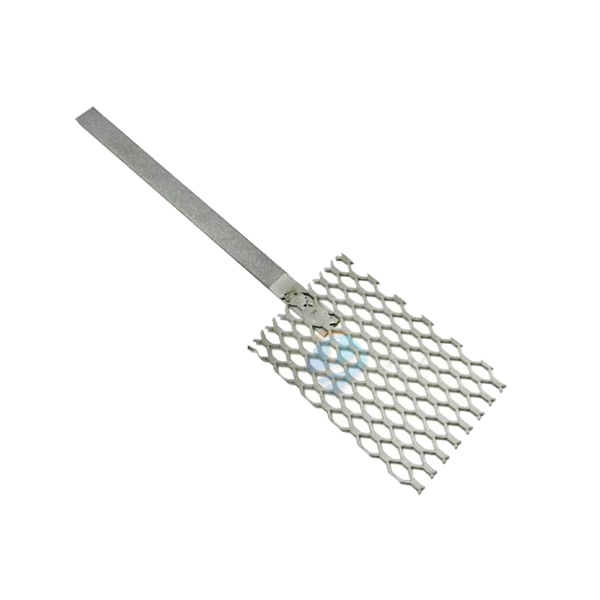

Platinum-coated titanium electrode

Effective overpotential

Reusable

Excellent current density and production capacity

Customizable geometry of oxide-coated titanium anodes

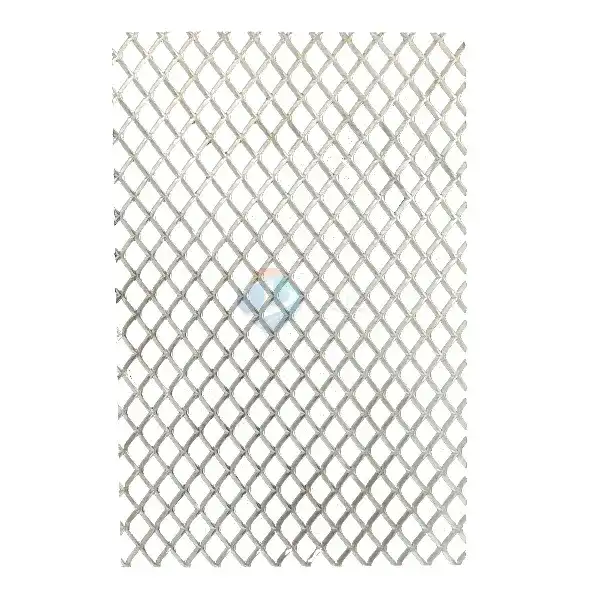

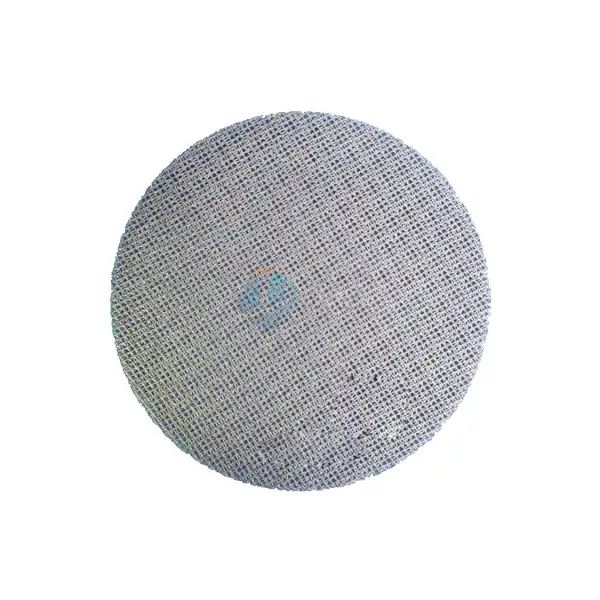

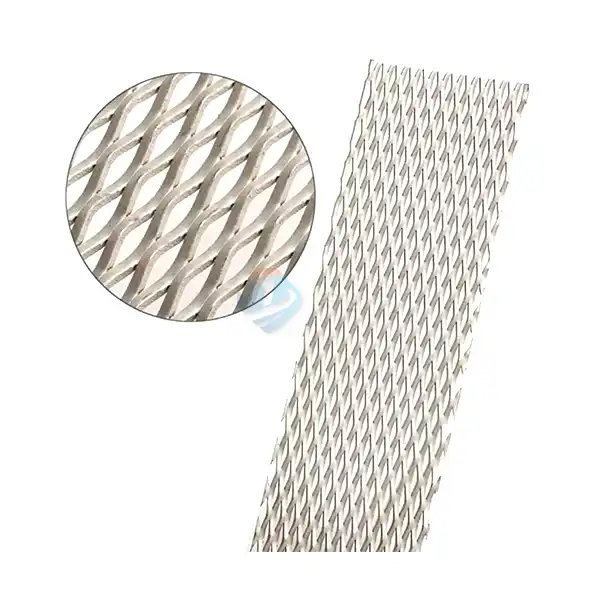

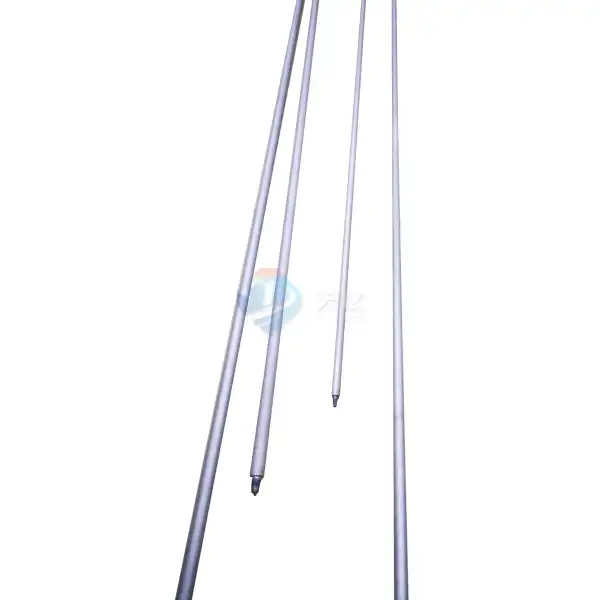

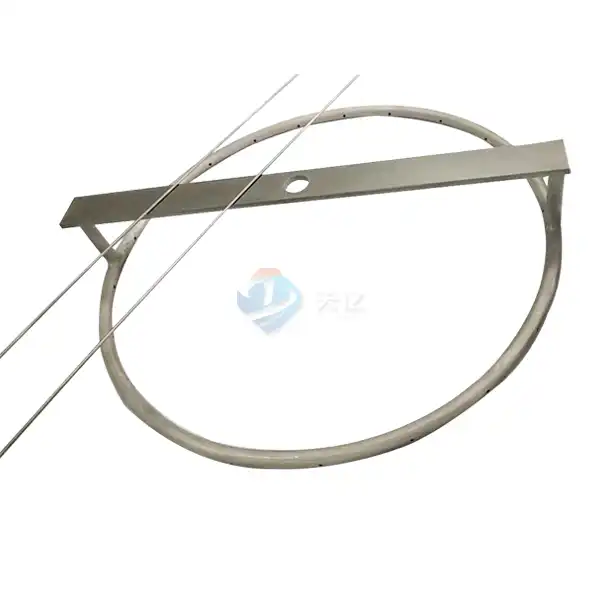

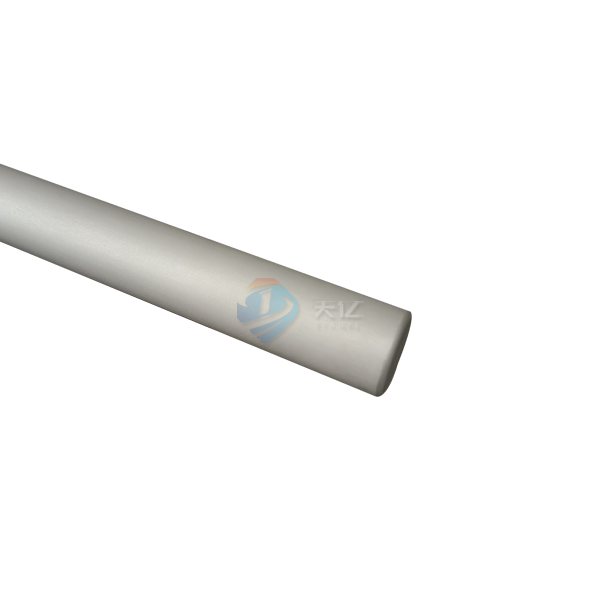

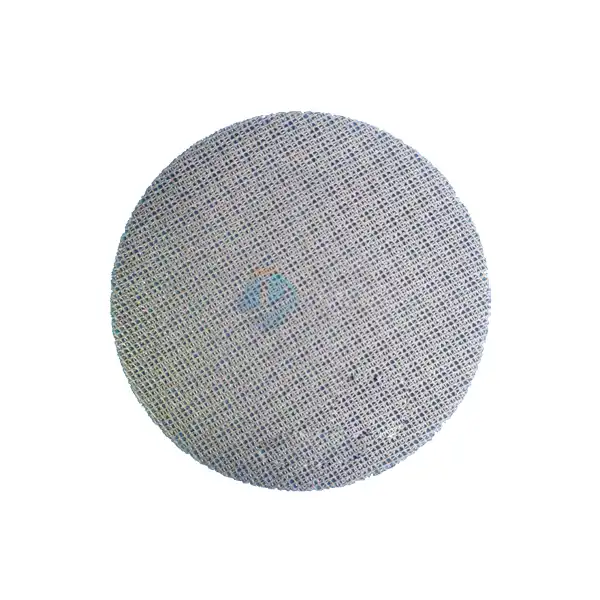

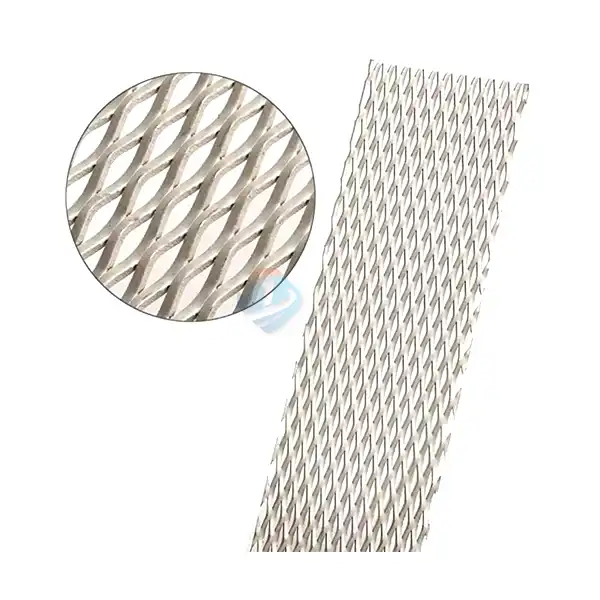

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Platinum-coated Titanium Electrode Introduction

Platinum-coated titanium electrode is a layer of platinum or platinum metal oxides coated on titanium substrate. It is lasting, non-consumable and insoluble in the electrolyte, It is widely used in electroplating and cathodic protection field.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

The Platinum-coated titanium electrode consists of a high-quality titanium substrate coated with a layer of platinum. This combination ensures high electrical conductivity and excellent resistance to corrosion, making it suitable for use in harsh environments. The electrodes can be customized in various dimensions to meet specific application requirements, ensuring optimal performance. Electrodes with MMO coatings are also used in other types of electrochemical advanced oxidation processes (EAOPs) for the treatment of organic wastewater. These processes rely on the generation of strong oxidizing agents like hydroxyl radicals to break down contaminants, and the MMO coating can enhance the electrodes' ability to generate these radicals efficiently .

Product Advantages

- High Durability: The robust titanium base combined with platinum coating enhances longevity and performance.

- Corrosion Resistance: Ideal for use in aggressive chemical environments due to its superior resistance to corrosion.

- Versatility: Suitable for a wide range of applications across different industries.

- Custom Solutions: Tailored to meet the unique specifications of each client.

Technical Features

- Low Overpotential: Ensures efficient the electrochemical reactions.

- Stable Performance: Maintains functionality over extended periods, reducing the need for frequent replacements.

- High Efficiency: Optimizes energy consumption in electrochemical processes.

Product Application

The Platinum-coated titanium electrode is extensively used in various applications, including:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our platinum-coated titanium electrode production process follows strict quality the control measures, ensuring that each electrode meets the highest industry standards. The process includes:

Titanium Substrate Preparation: Cutting, cleaning, and surface treatment.

Pre-Plating Treatment: Activation of the titanium surface for optimal adhesion.

Platinum Electroplating: Precisely controlled deposition of platinum coating.

Post-Plating Treatment: Annealing and quality inspection.

Packaging and Shipping: Careful packing to ensure safe delivery.

Quality Inspection

Every Platinum-coated titanium electrode undergoes comprehensive inspections to guarantee its quality. Our quality control team performs tests at multiple stages, from raw material evaluation to final product analysis, ensuring compliance with industry benchmarks.

Packaging Method

We prioritize safe and efficient packaging to protect our products during transit. Our packaging solutions include:

- Custom Packaging: Tailored to the electrode dimensions.

- Secure Materials: Ensures safe delivery without damage.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer OEM services, providing customized solutions to meet your specific needs. Whether you require unique designs, dimensions, or specifications, our team is ready to assist. The development of MMO coatings involves innovative methods to ensure that the coating adheres well to the substrate and provides a stable, long-lasting surface for electrochemical reactions. This can involve various synthesis methods, including heat treatment techniques that result in a coating with optimal porosity and corrosion resistance .

FAQ

Q1: What applications can the products be used for?

A1: It is commonly used in electroplating, water treatment, and electrosynthesis.

Q2: How long does the electrode last?

A2: With proper use, our electrodes can last over 10 years.

Q3: Can I customize the size of the electrode?

A3: Yes, we offer customizable dimensions to suit your application needs.

Contact Us

For more information or to place an order for our Platinum-coated titanium electrode, please contact us at info@di-nol.com. Our dedicated team is here to assist you with any inquiries or custom requests.