Titanium Electrodes for Water Ionization

Reusable

Excellent current density and production capacity

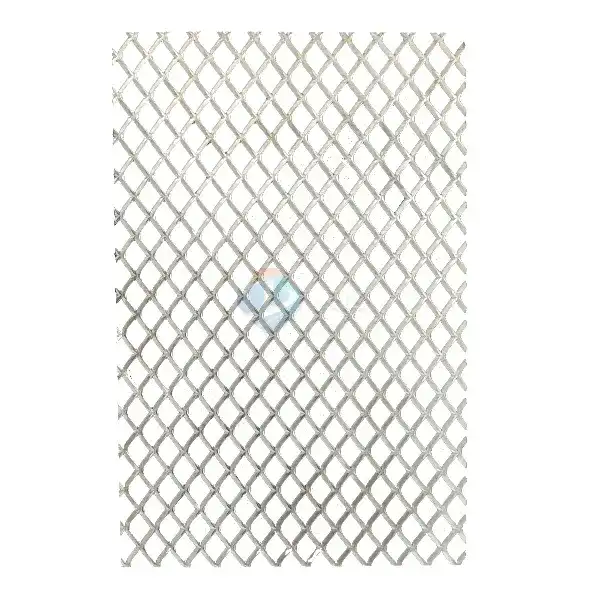

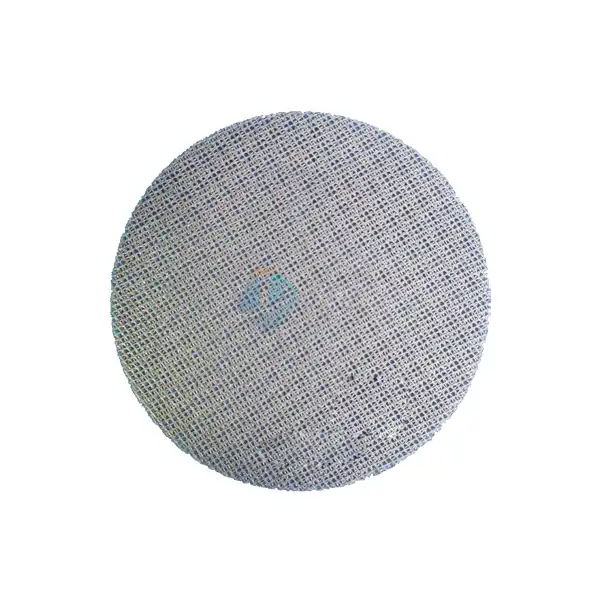

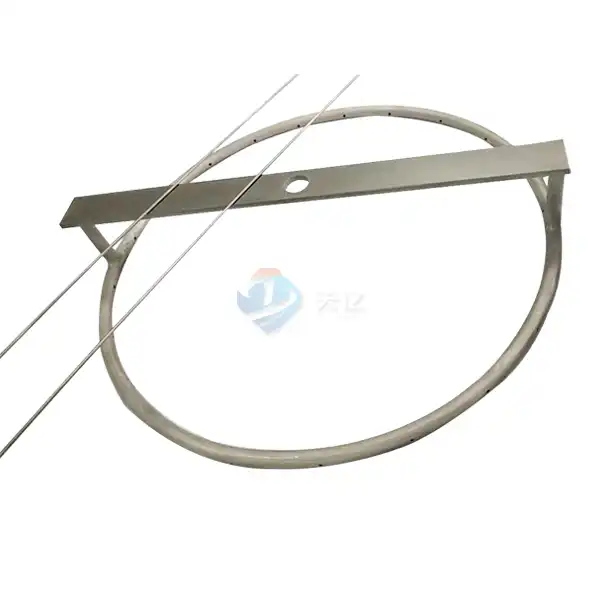

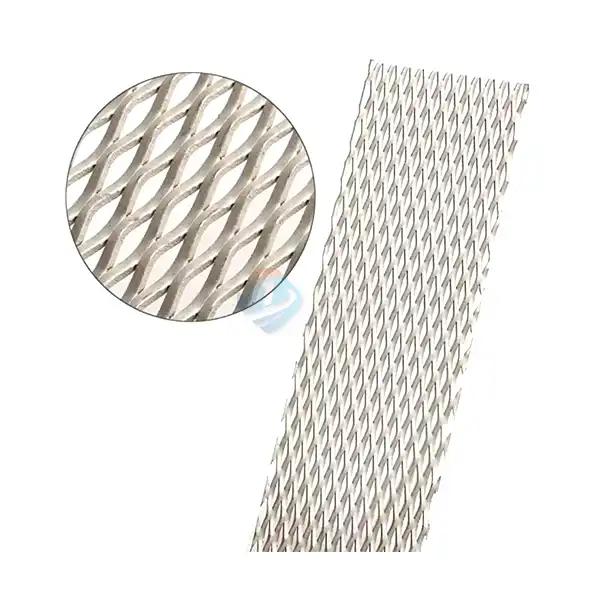

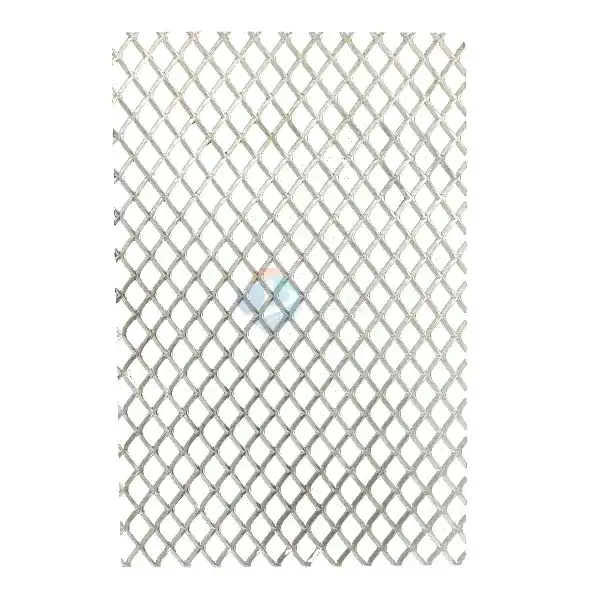

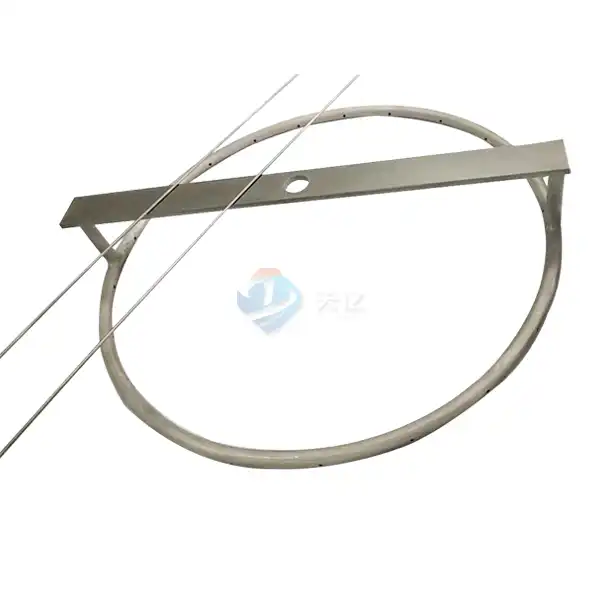

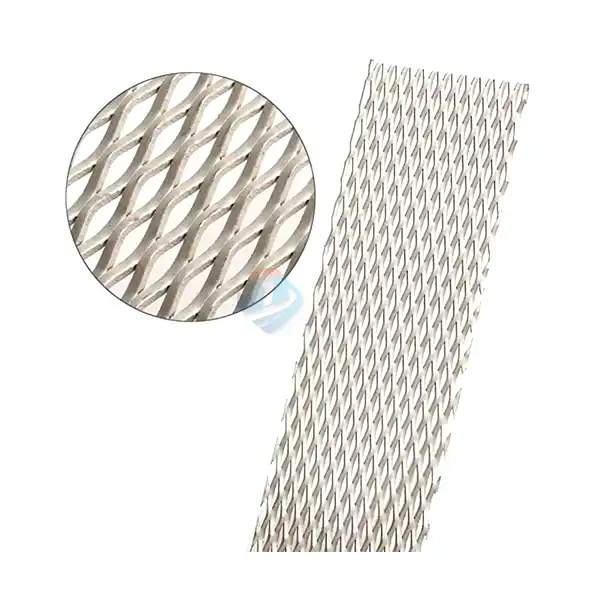

Customizable geometry of oxide-coated titanium anodes

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Titanium Electrodes for Water Ionization Introduction

The crucial component of a water ionizer is its plates or “electrodes”. Titanium Electrodes for Water Ionization are immersed in the water and send positive DC voltage into one side of the ionizer to make acid water, and negative into the other side to make alkaline water. By good water ionizer electrode, it may increase the electrolysis efficiency and get very many antioxidants in your drinking water.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

Product Composition and Design

Our titanium electrode for water ionizers is composed of high-grade titanium coated with MMO, which significantly improves its conductivity and resistance to corrosion. This unique design ensures effective electrolysis, optimizing the ionization process in water. The electrodes are available in various lengths and specifications to suit different water ionizer models.

Product Advantages

- Corrosion Resistance: The titanium material and MMO coating offer superior resistance to corrosion, ensuring a longer lifespan.

- High Conductivity: Enhanced conductivity allows for more efficient ionization, improving water quality.

- Customizable Design: We provide tailored solutions to fit specific customer needs, including size and coating options.

- Eco-Friendly: Our electrodes contribute to a sustainable approach to water purification.

Technical Features

- Advanced Electrolytic Technology: Our electrodes leverage cutting-edge technology to facilitate efficient water ionization.

- Durable Construction: Built to withstand harsh conditions, our electrodes maintain performance over extended periods.

- Easy Installation: Designed for compatibility with most water ionizer systems, ensuring a hassle-free setup.

Titanium Electrodes for Water Ionization Application

Electro-deionization (EDI): Titanium electrodes are integral to the EDI process, which is used to produce ultrapure water. EDI combines ion-exchange resin (IER) with electrodialysis (ED) to remove ions from water, using electricity instead of harmful chemicals for resin regeneration, thus eliminating waste streams associated with chemical regeneration .

Capacitive Deionization (CDI): Titanium electrodes are also used in CDI, an energy-efficient water desalination technology. CDI uses porous electrode materials to form electrical double layers that adsorb salt ions from water. The use of titanium electrodes can enhance the adsorption capacity and energy efficiency of the CDI process .

Desalination: Titanium electrodes can be employed in desalination processes to remove salts and minerals from seawater or brackish water. They contribute to the efficiency and effectiveness of the process by facilitating the separation of ions .

Water Treatment: In water treatment facilities, titanium electrodes can be used to remove heavy metal ions and other contaminants, producing high-quality water suitable for industrial use .

Organic Pollutant Removal: Coupled with other processes like photoelectrochemical (PEC) oxidation, titanium electrodes can be used to degrade organic pollutants in brackish water, making it safer for drinking or domestic use .

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process involves the following steps:

Material Selection

The process begins with selecting high-quality titanium, typically Grade 1 or Grade 2, known for its excellent corrosion resistance and biocompatibility, making it ideal for use in water ionization systems.

Cutting and Shaping

Titanium plates are cut into the required shapes and sizes using precision cutting techniques such as laser cutting or CNC machining. This ensures accurate dimensions tailored to the specific design of the water ionizer.

Surface Preparation

The cut titanium electrodes undergo a surface cleaning process to eliminate any contaminants, such as oils or dust. This is usually achieved through ultrasonic cleaning, followed by rinsing with deionized water to ensure a pristine surface.

Surface Treatment

To enhance the adhesion of any coatings and improve performance, the titanium surfaces may be treated using methods like sandblasting or acid etching, which create a roughened surface texture.

Coating Application (if required)

If specified for enhanced performance, a coating is applied to the titanium electrodes. This often involves depositing a layer of mixed metal oxides (MMO) using electrodeposition techniques, which provide additional electrochemical properties beneficial for ionization.

Coating Thickness Monitoring

During the coating process, the thickness is monitored using techniques such as laser scanning or X-ray fluorescence to ensure that it meets the predetermined specifications for optimal performance.

Quality Inspection

Every titanium electrode undergoes rigorous quality checks throughout the production process. This includes:

- Raw Material Testing: Ensuring the quality of titanium used.

- Coating Inspection: Verifying the integrity of the MMO coating.

- Performance Testing: Conducting tests to ensure the electrodes meet industry standards for efficiency and durability.

Packaging Method

Our titanium electrode for water ionizers are packaged with care to prevent damage during transit. We use:

- Protective Wrapping: To cushion the electrodes.

- Custom Boxes: Ensuring safe and efficient delivery.

- Eco-Friendly Materials: Committed to sustainability, we utilize recyclable packaging options.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing clients to customize electrodes according to their specific requirements. From unique coatings to branding options, we are dedicated to providing tailor-made solutions that meet the needs of every customer.

FAQ

Q1: How long does the titanium electrode last?

A1: Our titanium electrodes have a lifespan of over 5,000 hours under normal operating conditions.

Q2: Can I customize the size of the electrode?

A2: Yes, we provide customizable lengths to fit various water ionizer models.

Q3: What are the health benefits of using a water ionizer?

A3: Water ionizers produce alkaline water that may enhance hydration, improve metabolism, and provide antioxidant properties.

Q4: Is installation difficult?

A4: No, our electrodes are designed for easy installation with most water ionizer systems.

Q5: Do you provide after-sales support?

A5: Yes, we offer comprehensive after-sales support, including technical assistance and maintenance services.

Contact Us

For more information about our titanium electrode for water ionizer and to discuss your specific needs, please reach out to us at info@di-nol.com. Let Shaanxi Tianyi be your trusted partner in enhancing water quality and promoting health through advanced electrochemical technologies.