electrolysis titanium electrode

Effective overpotential

Reusable

Excellent current density and production capacity

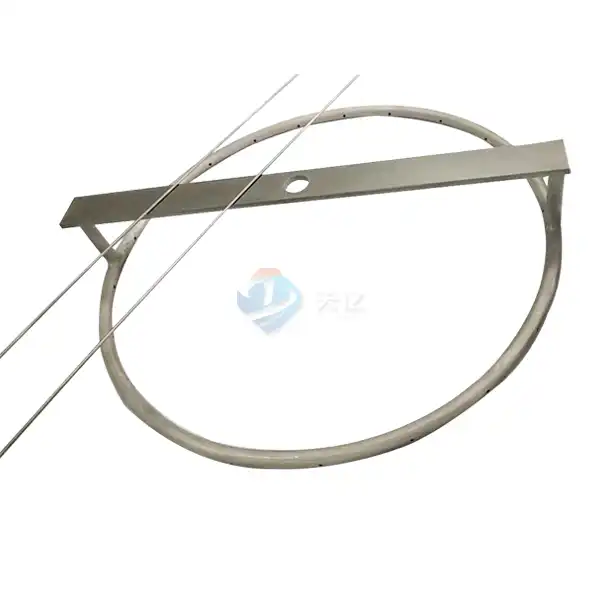

Customizable geometry of oxide-coated titanium anodes

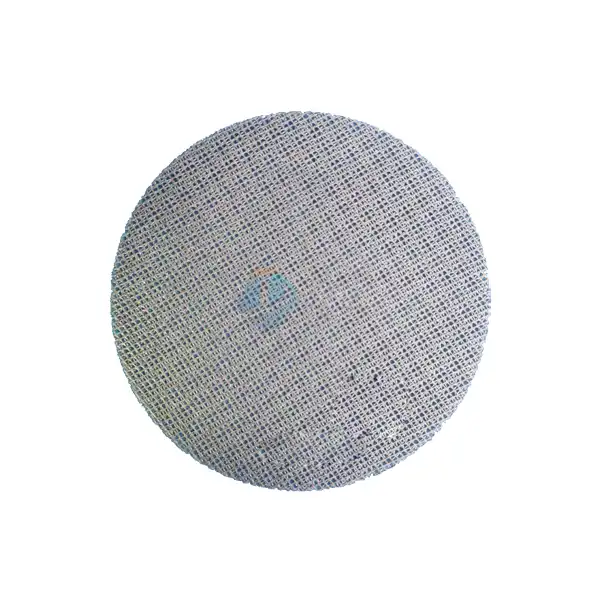

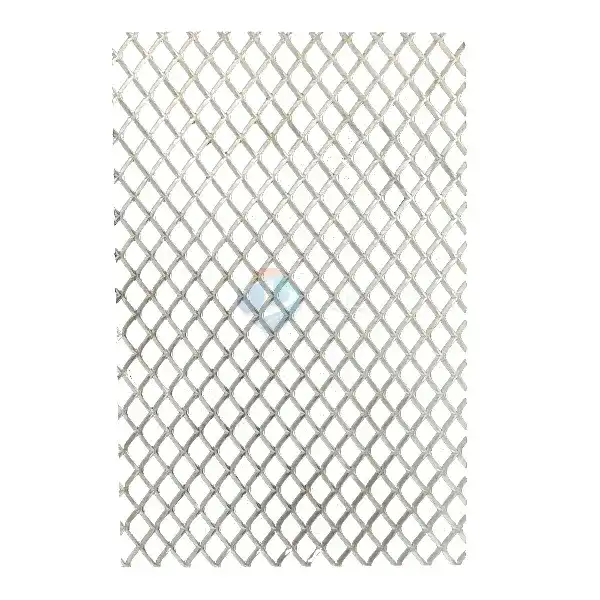

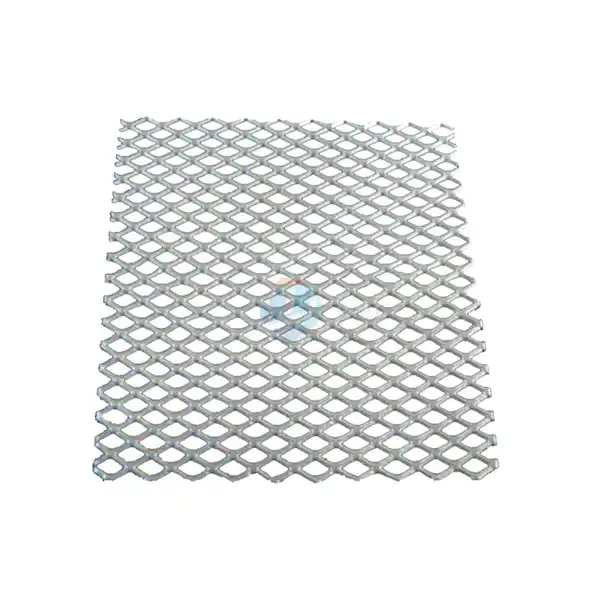

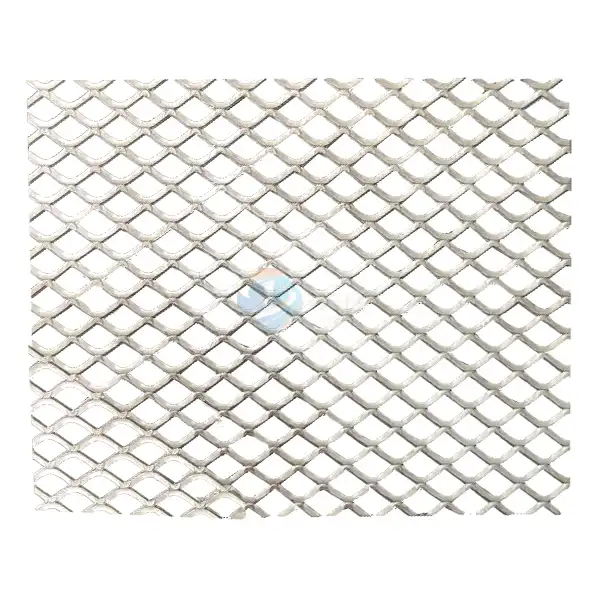

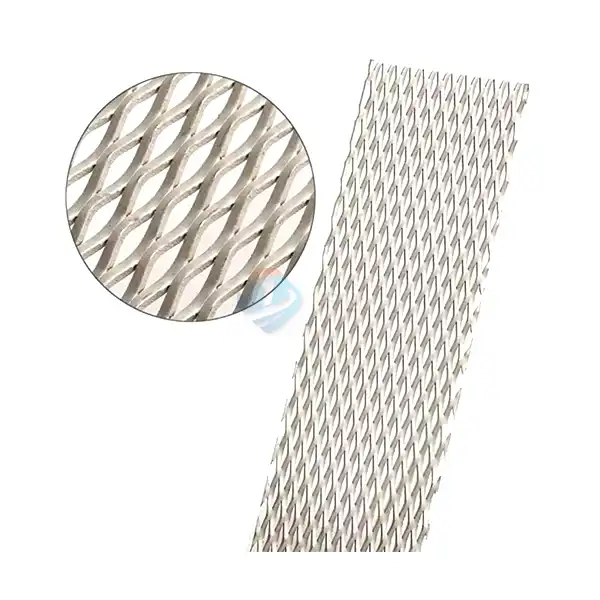

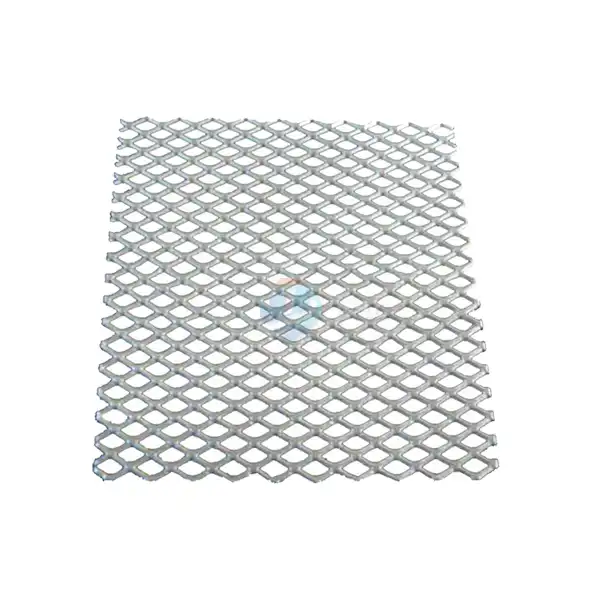

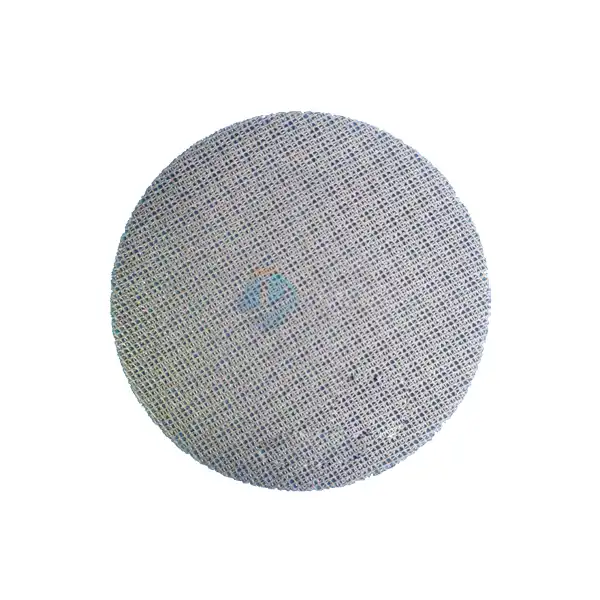

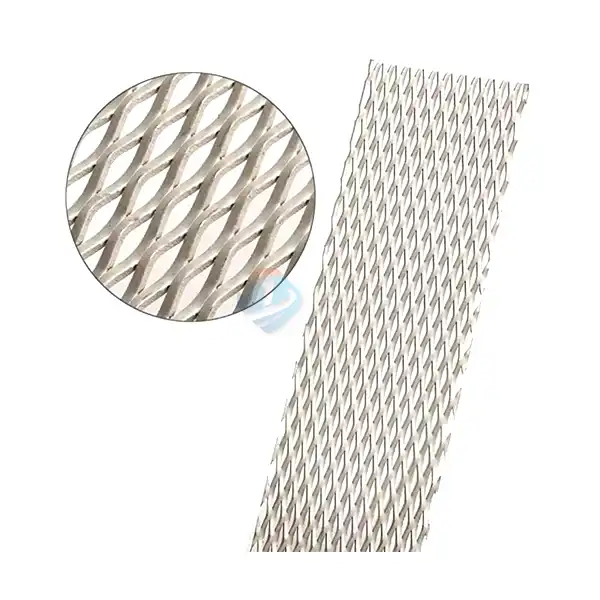

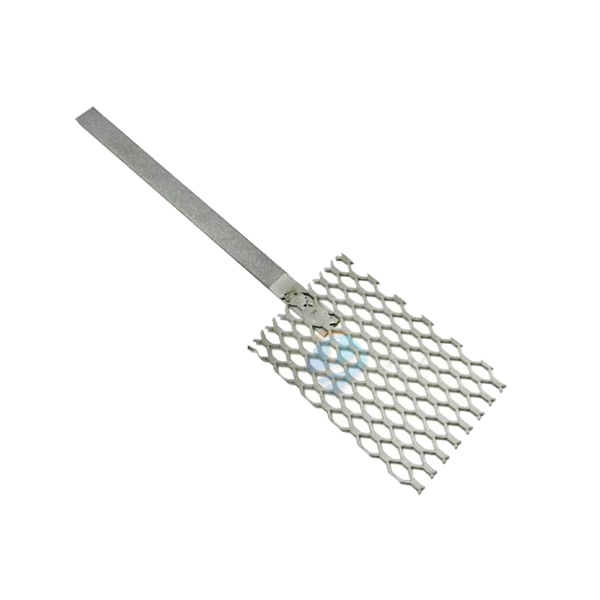

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., your trusted partner in advanced electrochemical solutions. Our electrolysis titanium electrodes are crafted from high-performance Mixed Metal Oxide (MMO) coated titanium, ensuring exceptional durability and efficiency for a wide range of applications. These electrodes are designed to withstand harsh electrochemical environments, making them perfect for industries such as water treatment, electroplating, and hydrogen production.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

Our electrolysis titanium electrodes are engineered using a titanium substrate coated with a specialized MMO layer. This design enhances the electrode's electrochemical performance and longevity, allowing for efficient ion exchange and reduced corrosion rates. The electrodes are available in various shapes and sizes to meet specific client requirements.

Product Advantages

- High Durability: Resistant to corrosion and wear, ensuring long-lasting performance.

- Cost-Effective: Offers excellent value due to reduced maintenance and replacement needs.

- Customizable: Tailored designs to fit various applications and client specifications.

- Eco-Friendly: Supports sustainable practices in industries like water purification and electroplating.

Technical Features

- High Current Density: Supports efficient electrolysis processes, leading to faster reaction rates.

- Low Overpotential: Minimizes energy consumption during operation, enhancing overall efficiency.

- Wide Application Range: Suitable for diverse electrochemical applications, from industrial to environmental.

Product Application

Our electrolysis titanium electrodes are utilized in various sectors, including:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

At Shaanxi Tianyi, we employ state-of-the-art manufacturing techniques:

Material Acquisition

The process begins with the acquisition of high-grade titanium, known for its exceptional resistance to corrosion and mechanical strength, essential for reliable electrolysis applications.

Cleaning and Degreasing

Titanium pieces are thoroughly cleaned using a combination of solvent degreasing and ultrasonic cleaning methods. This removes any oils, dirt, or residues that could compromise the surface quality.

Surface Preparation

To enhance coating adhesion, the titanium surface undergoes preparation through sandblasting or acid etching. This treatment creates a roughened surface profile, improving the mechanical bond with subsequent coatings.

Coating Material Formulation

A specific electrochemical coating mixture is formulated, typically incorporating noble metals such as ruthenium or iridium oxides. The formulation is designed to optimize the electrode’s performance in electrolytic environments.

Coating Application

The coating is applied to the titanium substrate using advanced techniques like electrochemical deposition or sputtering. These methods ensure uniformity and proper thickness across the electrode surface.

Thermal Treatment

After coating, the electrodes are subjected to a thermal treatment process. This step enhances the adhesion of the coating to the titanium substrate and improves the overall durability of the electrode.

Performance Evaluation

Each titanium electrode undergoes comprehensive electrochemical performance testing in simulated operational conditions. Key performance metrics, including current efficiency and stability, are measured to ensure quality.

Quality Assurance

A final inspection process is implemented to verify the integrity of the electrode coating and the absence of defects. This ensures that only high-quality electrodes are approved for distribution.

Packaging for Distribution

Once passed through quality assurance, the titanium electrodes are carefully packaged to prevent damage during shipping. Each package includes product specifications and handling instructions for end-users.

Quality Inspection

We maintain stringent quality control measures throughout the production process. Each batch of electrodes is subjected to thorough inspections for durability, corrosion resistance, and performance, ensuring they exceed customer expectations. Electrodes with MMO coatings are also used in other types of electrochemical advanced oxidation processes (EAOPs) for the treatment of organic wastewater. These processes rely on the generation of strong oxidizing agents like hydroxyl radicals to break down contaminants, and the MMO coating can enhance the electrodes' ability to generate these radicals efficiently .

Packaging Method

Our electrolysis titanium electrodes are packaged securely to prevent damage during transit. We offer various packaging options, including custom solutions to meet the specific needs of our clients.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi provides comprehensive OEM services, allowing you to customize your products according to your unique requirements. We collaborate closely with clients to develop tailored solutions that ensure optimal performance and longevity.

FAQ

Q: What industries can benefit from electrolysis titanium electrodes?

A: Industries such as water treatment, electroplating, and hydrogen production can significantly benefit from our electrodes due to their efficiency and durability.

Q: How long do the electrodes typically last?

A: Our products have a service life of over 10,000 hours, depending on the application and operating conditions.

Q: Can I customize the dimensions of the electrodes?

A: Yes, we offer customizable designs to meet your specific application requirements.

Contact Us

Ready to enhance your electrochemical processes with our advanced electrolysis titanium electrodes? Contact us today at [info@di-nol.com] for more information or to place an order. Our dedicated team is here to assist you with any questions and provide the tailored solutions you need.