titanium electrodes

Effective overpotential

Reusable

Excellent current density and production capacity

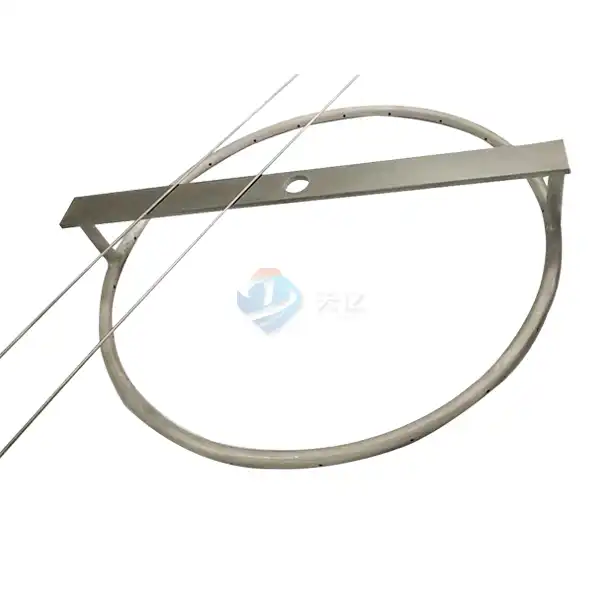

Customizable geometry of oxide-coated titanium anodes

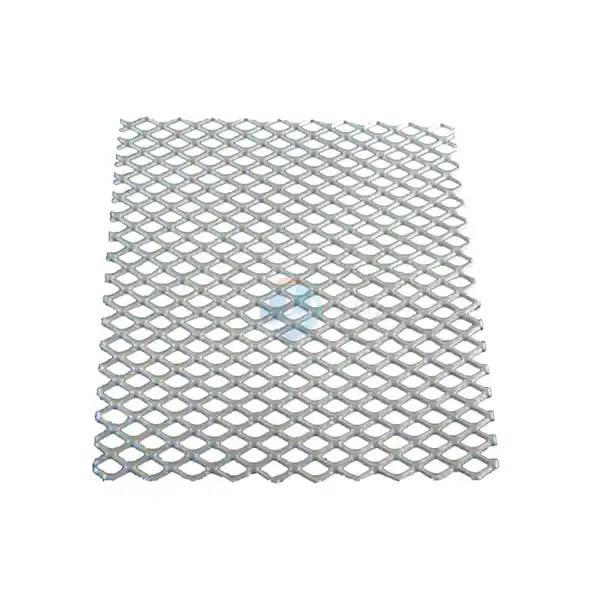

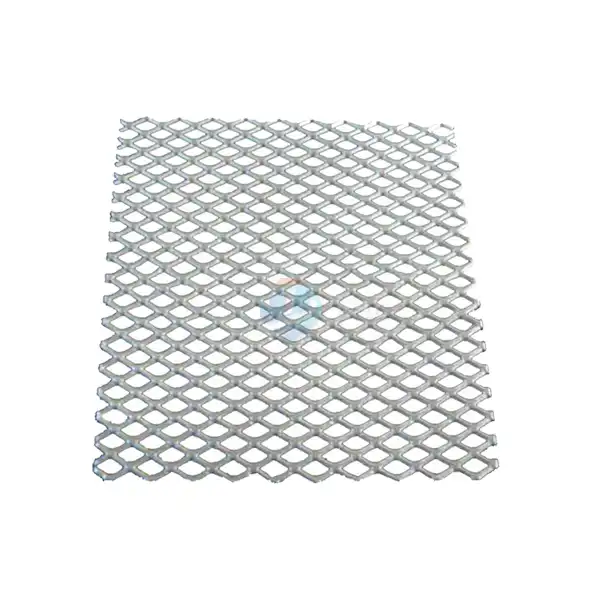

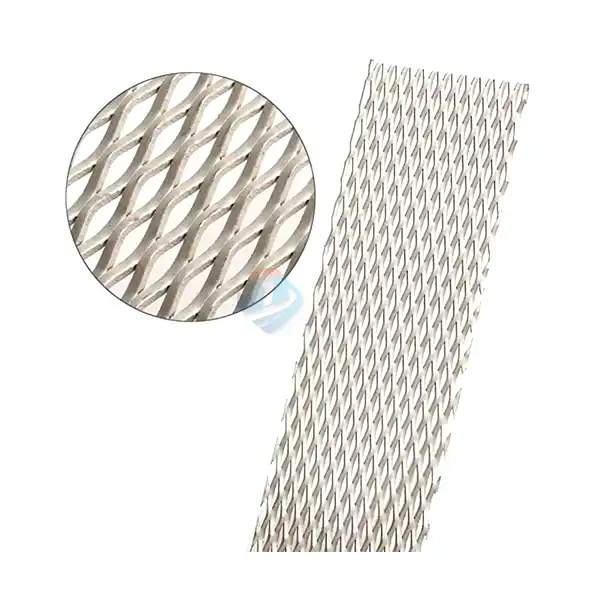

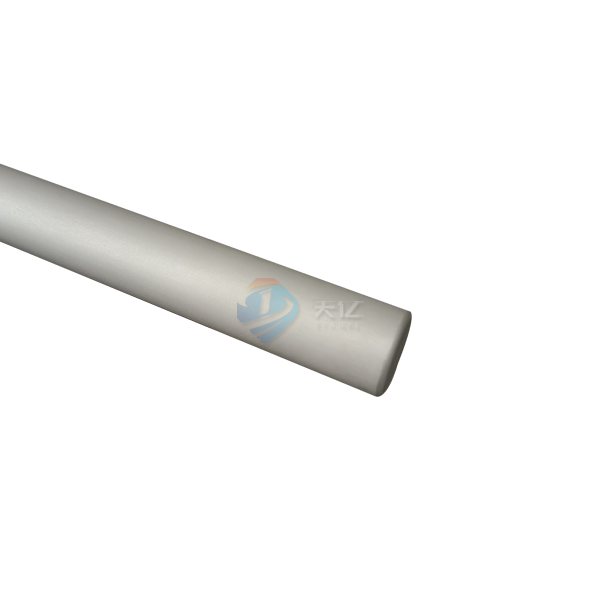

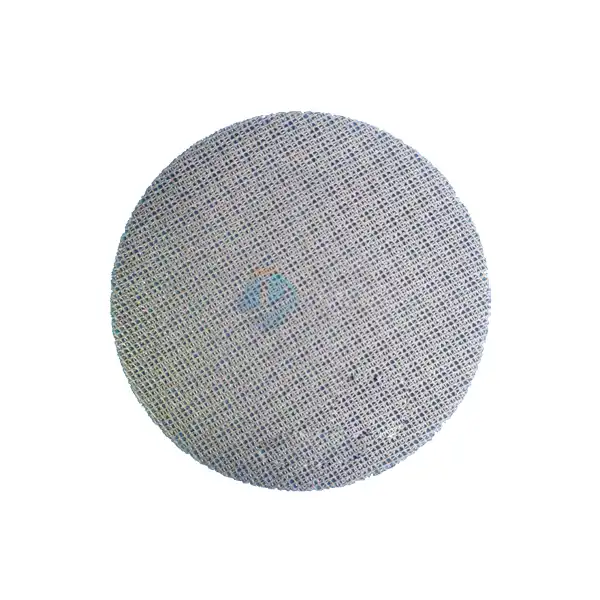

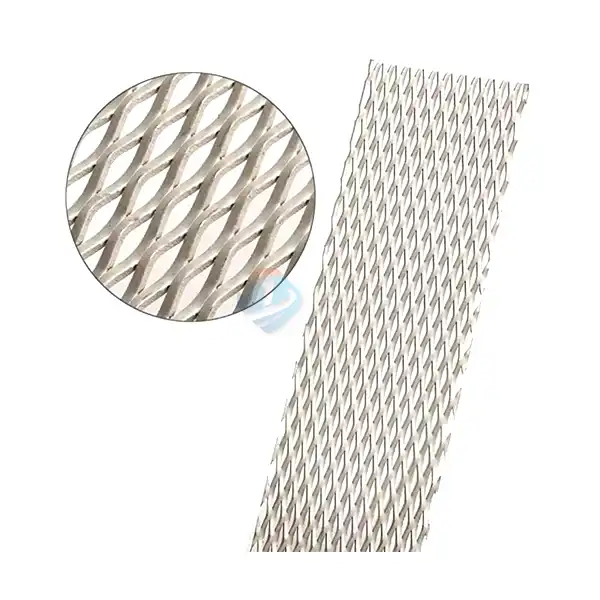

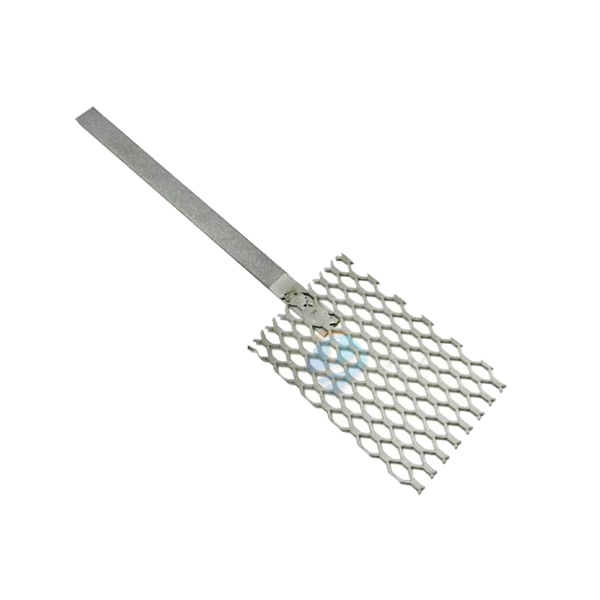

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., your trusted partner for cutting-edge titanium electrodes. Our advanced MMO (Mixed Metal Oxide) coated titanium anodes are engineered for superior performance in various electrochemical applications, including industrial electroplating, water treatment, and cathodic protection. With a commitment to innovation and sustainability, we provide solutions that meet the highest standards of efficiency and environmental compliance.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

Our products are composed of high-quality titanium alloys, ensuring exceptional strength and corrosion resistance. The innovative coatings enhance their electrochemical performance, making them suitable for various harsh environments. Our electrodes are designed to optimize current distribution and minimize energy loss, leading to improved operational efficiency.

Product Advantages

- Corrosion Resistance: Our titanium electrodes withstand harsh chemical environments, ensuring longevity and reliability.

- High Performance: Engineered for efficiency, our electrodes provide excellent current efficiency and stable performance.

- Customization: We offer the tailored solutions to meet specific client needs, ensuring optimal performance for unique applications.

- Sustainability: Our products support eco-friendly technologies, contributing to global environmental protection efforts.

Technical Features

- Low Overpotential: Reduced energy loss during the operation enhances overall efficiency.

- Durable Coatings: Our coatings are resistant to wear and degradation, extending the lifespan of the electrodes.

- Wide Application Range: Suitable for various industries, including water treatment, mining, and electroplating.

Product Application

Shaanxi Tianyi's titanium electrodes are used across multiple industries, including:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our state-of-the-art manufacturing the process incorporates advanced technology and strict quality control measures:

Material Selection

High-purity titanium is selected for electrode production due to its superior corrosion resistance, high strength-to-weight ratio, and excellent electrochemical properties, making it suitable for various applications.

Surface Cleaning

The titanium materials undergo a thorough cleaning process to eliminate any contaminants. This includes solvent cleaning followed by rinsing with distilled water to ensure a pristine surface free of oils, dust, and residues.

Surface Roughening

To enhance the bonding strength of any coatings, the titanium surface is mechanically or chemically roughened. Techniques such as grit blasting or acid etching create a textured surface that improves adhesion.

Coating Preparation

Depending on the application, a coating material, such as mixed metal oxides or iridium oxide, is prepared in a controlled environment. The composition is designed to optimize the electrochemical performance of the electrodes.

Coating Application

The coating is applied to the prepared titanium substrate using methods like thermal spraying, electroplating, or chemical vapor deposition. This ensures a consistent and uniform layer over the entire surface area.

Curing Process

The coated electrodes undergo a curing process at elevated temperatures, which promotes the bonding of the coating to the titanium substrate. This step enhances the durability and electrochemical properties of the electrodes.

Electrochemical Performance Testing

Each titanium electrode is subjected to extensive testing to assess its electrochemical performance under various conditions. Parameters such as current efficiency, stability, and activation overpotential are evaluated.

Final Quality Control

The electrodes are inspected for surface imperfections and coating uniformity. This quality control step is vital for ensuring that only electrodes meeting stringent standards are packaged for distribution.

Packaging and Shipping

Once the electrodes pass inspection, they are carefully packaged to prevent damage during transport. Each package includes product specifications, handling instructions, and safety information for users.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. We conduct comprehensive inspections to ensure each titanium electrode meets industry benchmarks for performance and reliability. Our quality assurance process about titanium electrodesincludes:

- Material testing

- Coating thickness verification

- Performance testing under simulated operational conditions

Packaging Method

We prioritize safety and efficiency in our packaging. Each titanium electrode is securely packed to prevent damage during transportation, with options for custom packaging tailored to specific shipping needs.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer OEM and ODM capabilities to provide customized solutions that align with our clients' requirements. From design to production, we ensure that every product meets exact specifications for optimal performance.

FAQ

What industries use the products?

They are widely used in water treatment, electroplating, hydrometallurgy, and organic electro-synthesis.How long do the product last?

Our electrodes can last up to 10 years under optimal conditions, depending on the application.Can I customize the specifications of the electrodes?

Yes, we provide fully customizable solutions tailored to meet specific client needs.What is the operating voltage of your products?

Our products can operate at voltages up to 30V.How do you ensure the quality of your products?

We conduct rigorous quality inspections at every stage of production to ensure compliance with industry standards.

Contact Us

For more information about our titanium electrodes or to discuss your specific requirements, please reach out to us at [info@di-nol.com]. We look forward to partnering with you for your electrochemical solutions!