Platinum-titanium anode plate

Effective overpotential

Reusable

Excellent current density and production capacity

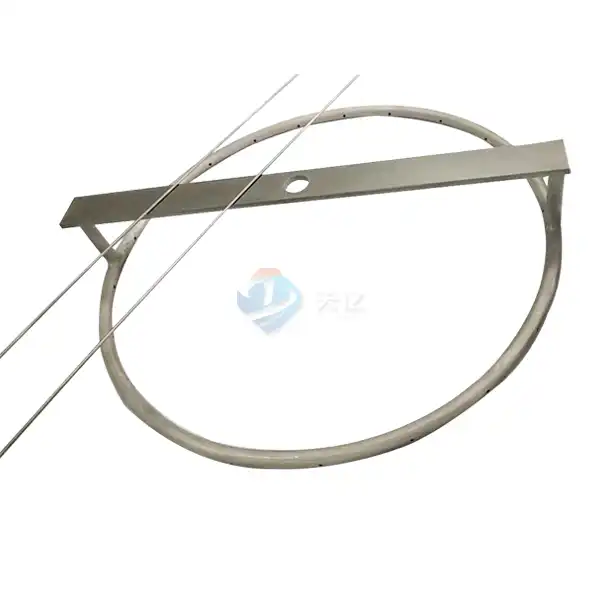

Customizable geometry of oxide-coated titanium anodes

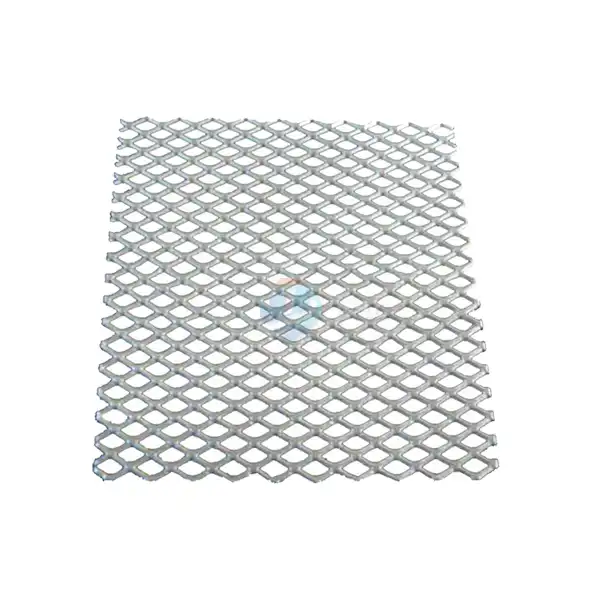

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Platinum-titanium Anode Plate Introduction

At TianYI, we specialize in high-quality Platinum-titanium anode plate designed for various industrial applications. Our products offer exceptional corrosion resistance, long service life, and high conductivity. With advanced manufacturing processes and rigorous quality control, our anodes ensure reliable performance in demanding environments. When you choose TianYI, you invest in durability and efficiency, making our anode plates the preferred choice for leading companies in the electrochemical, water treatment, and oil industries.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

Product Composition and Design

Our Platinum-Titanium Anode Plates are crafted from premium titanium substrates coated with a layer of platinum. This combination ensures exceptional corrosion resistance and durability, making them ideal for demanding environments. The design can be customized to meet specific application needs, ensuring optimal performance and longevity.

Product Advantages

- High Corrosion Resistance: The platinum coating provides outstanding protection against the harsh chemicals.

- Durability: Our anodes are built to last, reducing the need for frequent replacements.

- Customizable: Tailored solutions available to fit various applications and specifications.

- Eco-Friendly: Contributes to sustainable practices by enhancing efficiency in water treatment processes.

Technical Features

- Stable Performance: Maintains consistent output over time, even in challenging conditions.

- High Current Density: Optimized for maximum efficiency during operation.

- Lightweight Design: Easy to handle and install without compromising on strength.

Product Application

The Platinum-Titanium Anode Plates are widely used in industries such as:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection: High-purity platinum and titanium.

Alloy Formation: Advanced alloying techniques.

Precision Cutting: State-of-the-art cutting equipment.

Surface Treatment: Anti-corrosion coatings.

Quality Inspection: Rigorous testing for performance and durability.

Quality Inspection

We conduct thorough quality checks throughout the production lifecycle. Each anode plate undergoes inspection for material integrity, coating uniformity, and performance testing to ensure compliance with industry standards.

Packaging Method

Our Platinum-Titanium Anode Plates are securely packaged to prevent damage during transport. We use custom packaging solutions that are both protective and cost-effective, ensuring safe delivery to our customers.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, providing tailored solutions that align with your specific requirements. Whether you need custom sizes or specialized coatings, we are here to meet your needs. Electrodes with MMO coatings are also used in other types of electrochemical advanced oxidation processes (EAOPs) for the treatment of organic wastewater. These processes rely on the generation of strong oxidizing agents like hydroxyl radicals to break down contaminants, and the MMO coating can enhance the electrodes' ability to generate these radicals efficiently .

FAQ

Q: What is the lifespan of the product?

A: The lifespan can vary based on application and environmental conditions, but our anodes are designed for long-term use.

Q: Can the anode plates be customized?

A: Yes, we provide fully customizable options to meet specific application needs.

Q: How do I order the products?

A: You can contact us directly through our website or at [info@di-nol.com] for inquiries and orders.

Contact Us

For more information on our Platinum-Titanium Anode Plates or to discuss your specific needs, please reach out to us at [info@di-nol.com]. At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we are dedicated to providing high-quality electrochemical solutions tailored to your requirements.

YOU MAY LIKE

VIEW MOREPlatinum-titanium anode

VIEW MOREPlatinum-titanium anode VIEW MOREplatinum coated titanium anode

VIEW MOREplatinum coated titanium anode VIEW MOREPlatinum-coated titanium mesh anode

VIEW MOREPlatinum-coated titanium mesh anode VIEW MOREPlatinum-coated titanium electrode

VIEW MOREPlatinum-coated titanium electrode VIEW MOREelectroplating titanium electrode

VIEW MOREelectroplating titanium electrode VIEW MOREelectrolysis titanium electrode

VIEW MOREelectrolysis titanium electrode VIEW MOREtitanium electrode for electrolysis

VIEW MOREtitanium electrode for electrolysis VIEW MOREtitanium electrode

VIEW MOREtitanium electrode