titanium electrode

Effective overpotential

Reusable

Excellent current density and production capacity

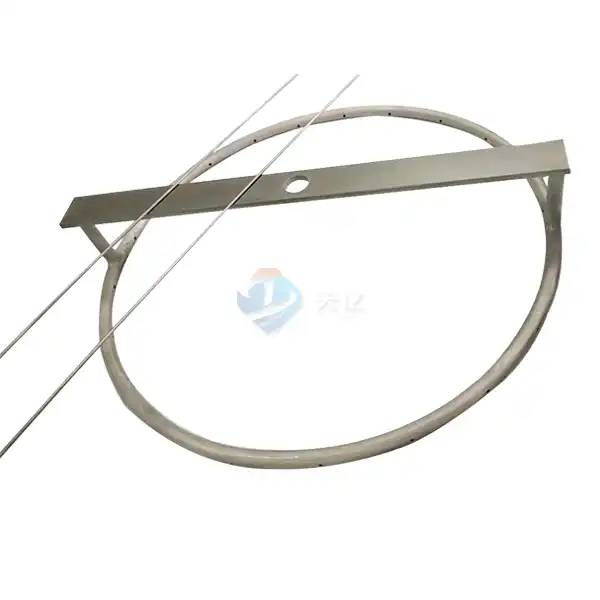

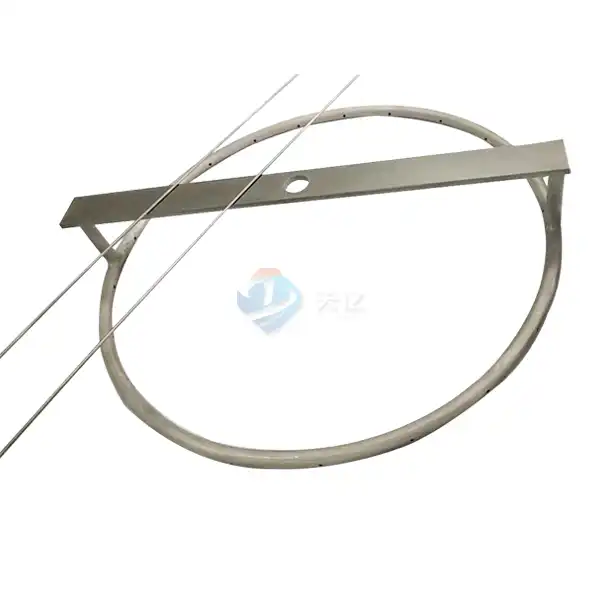

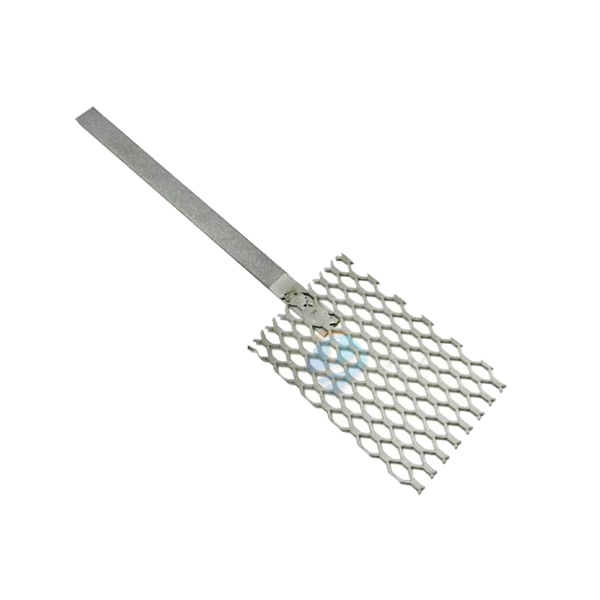

Customizable geometry of oxide-coated titanium anodes

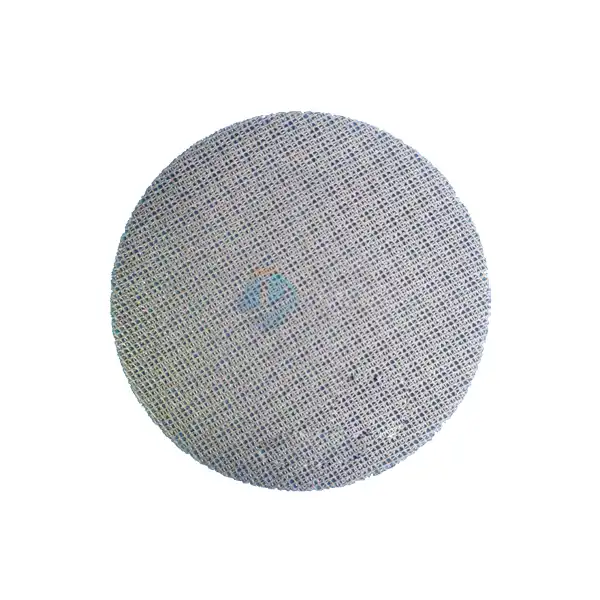

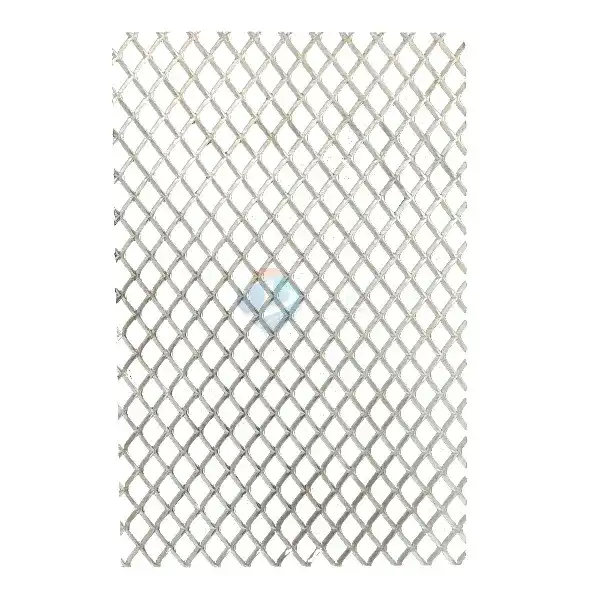

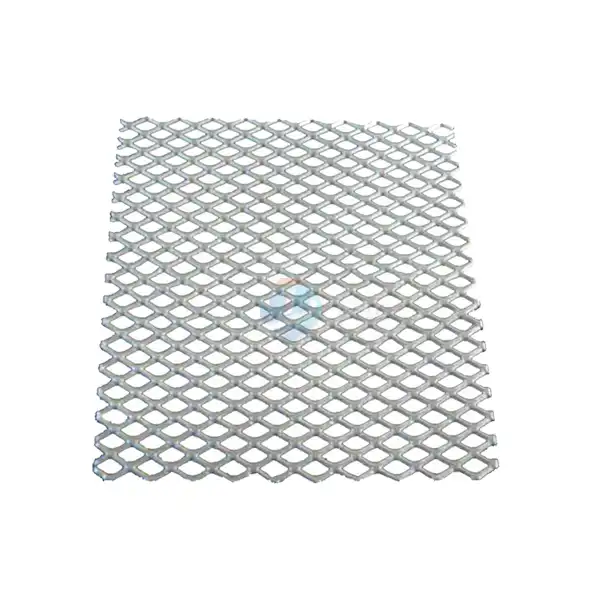

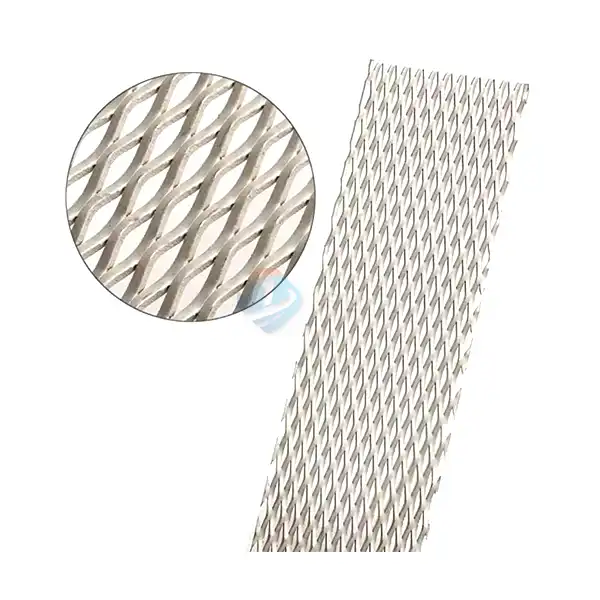

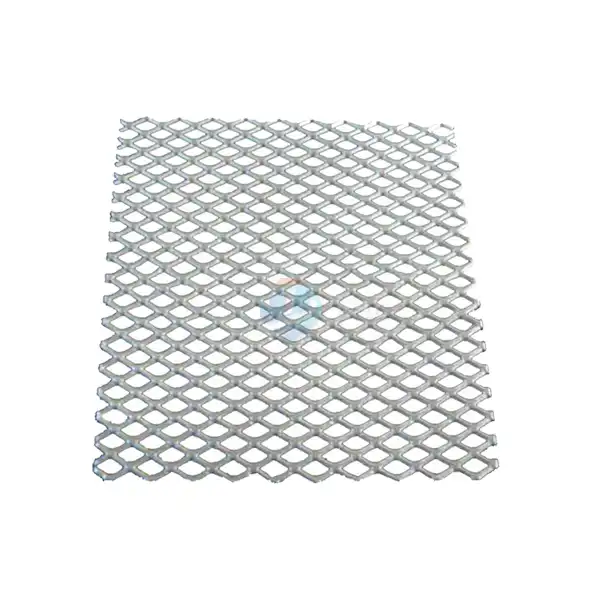

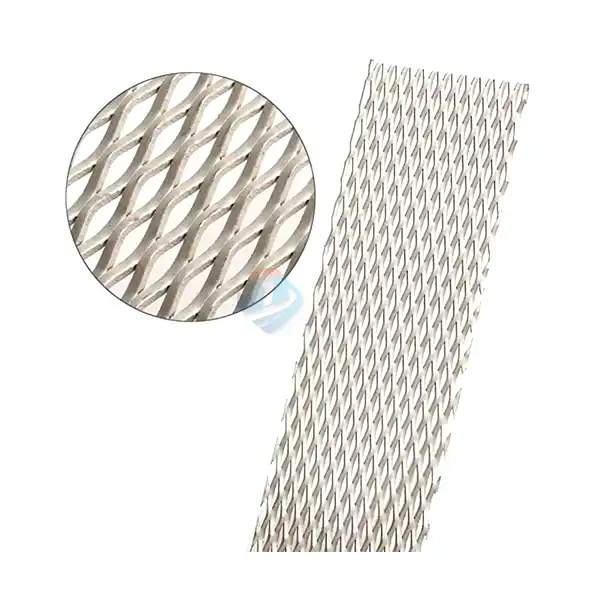

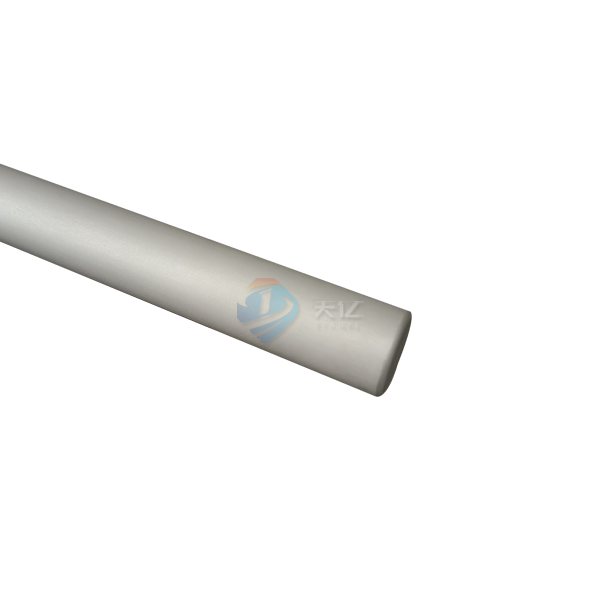

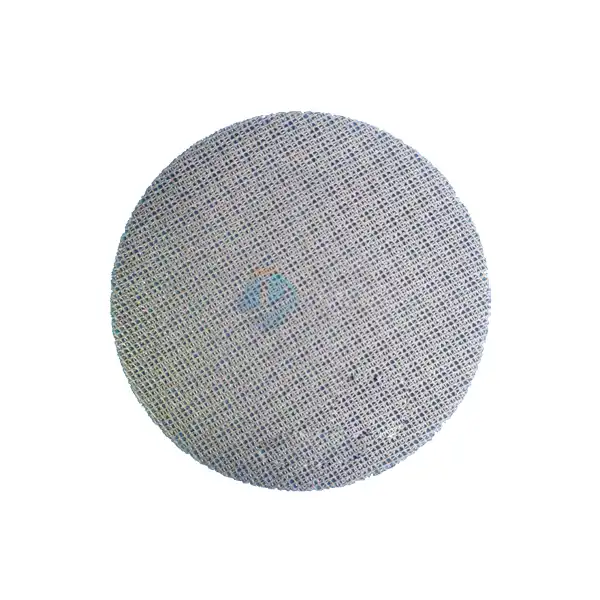

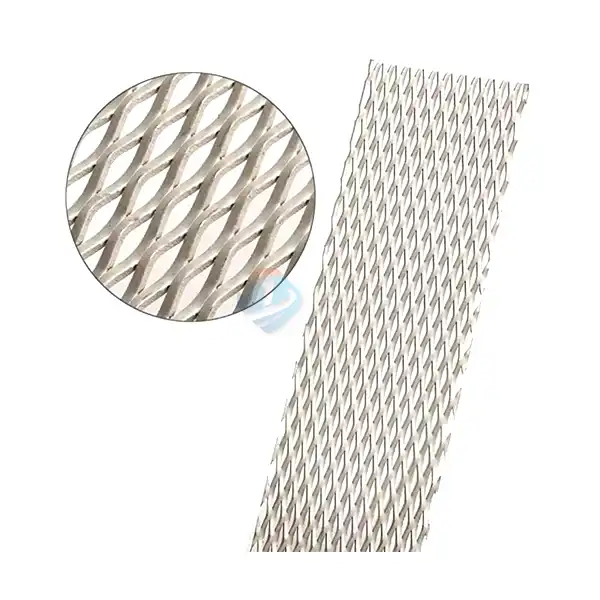

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to the world of titanium electrodes, where advanced technology meets reliability. At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we specialize in high-performance products, specifically our MMO (Mixed Metal Oxide) coated titanium anodes. These electrodes are essential for various applications, including industrial electroplating, water treatment, and cathodic protection, ensuring efficient and eco-friendly operations across multiple industries.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

Our titanium electrodes are crafted from high-quality titanium alloys, ensuring exceptional strength and corrosion resistance. The unique coating composition varies based on application requirements, typically featuring a blend of ruthenium, iridium, and tantalum, which enhances their electrochemical performance.

Product Advantages

- Durability: Exceptional resistance to corrosion and wear, extending the lifespan of the electrode.

- High Efficiency: Superior electrochemical performance ensures effective and reliable operation.

- Customizability: Tailored designs to meet specific application needs, whether for specialized coatings or electrode configurations.

Technical Features

- High Conductivity: Our products offer excellent electrical conductivity, improving overall system efficiency.

- Temperature Resistance: Designed to withstand high operating temperatures without compromising performance.

- Eco-Friendly: Contributes to sustainable practices through reduced energy consumption in various processes.

Product Application

Titanium electrodes are widely utilized in several key industries, including:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our manufacturing process adheres to the highest industry standards, ensuring that every titanium electrode is produced with precision:

Material Selection

High-purity titanium is chosen for the electrode fabrication process due to its excellent corrosion resistance and mechanical strength, which are crucial for effective performance in various electrochemical applications.

Surface Preparation

The titanium plates or rods undergo extensive surface cleaning to remove any contaminants. This includes ultrasonic cleaning and chemical degreasing to ensure a clean surface that is free from oils and residues.

Surface Texturing

To improve adhesion for coatings, the titanium surface is treated to create a rough texture. This can be accomplished through methods such as sandblasting or acid etching, enhancing the surface area for better coating performance.

Coating Application

Depending on the application, the titanium substrate may be coated with materials such as oxides or mixed metal oxides. Coating methods can include thermal spraying, electroplating, or chemical vapor deposition, ensuring a uniform application.

Curing and Sintering

After the coating is applied, the electrodes are subjected to a curing process at high temperatures. This step helps in solidifying the coating and improving the adhesion between the coating and the titanium substrate.

Electrochemical Testing

Each titanium electrode is rigorously tested for electrochemical performance, evaluating parameters such as current efficiency, stability, and catalytic activity under operational conditions. This testing ensures adherence to performance specifications.

Final Inspection

The finished electrodes are inspected for surface defects and uniformity of the coating. Any discrepancies are addressed before the product is approved for packaging, ensuring high-quality standards.

Packaging and Shipping

Once passed through quality control, the titanium electrodes are carefully packaged to prevent damage during transport. Each package includes documentation with product specifications, safety instructions, and handling guidelines for customers.

Quality is our top priority. Each titanium electrode undergoes extensive testing and inspection to guarantee it meets industry standards for durability and performance. Our quality control process includes:

- Material Testing: Ensuring raw materials meet strict specifications.

- Performance Testing: Conducting tests to confirm the electrochemical efficiency of the electrodes.

Packaging Method

We use safe and effective packaging solutions to ensure the integrity of our titanium electrodes during transit. Each product is securely packaged to prevent damage, and we offer customizable packaging options based on client requirements.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we pride ourselves on offering comprehensive OEM services that are meticulously tailored to meet the unique needs of our partners. Our experienced team works closely with clients to understand their specific requirements, whether that involves developing specialized coatings, precise dimensions, or bespoke packaging solutions. We are dedicated to delivering high-quality, customized products that not only align perfectly with your specifications but also enhance your overall product performance and market competitiveness. With a focus on collaboration and innovation, we strive to be a reliable partner in your success.

FAQ

Q: What applications can they be used for?

A: Our products are used in water treatment, electroplating, and cathodic protection, among other applications.

Q: How do you ensure the quality of your products?

A: We implement rigorous quality control processes at every manufacturing stage, from raw material inspection to final testing.

Q: Can I customize the specifications of the electrodes?

A: Yes, we offer fully customizable solutions to meet specific application requirements.

Q: What is the typical lifespan of your products?

A: With proper maintenance and usage, our products can last several years, significantly reducing replacement costs.

Contact Us

For more information about our titanium electrodes or to discuss your specific needs, please reach out to us at [info@di-nol.com]. Our team is ready to assist you in finding the best solutions for your electrochemical applications.