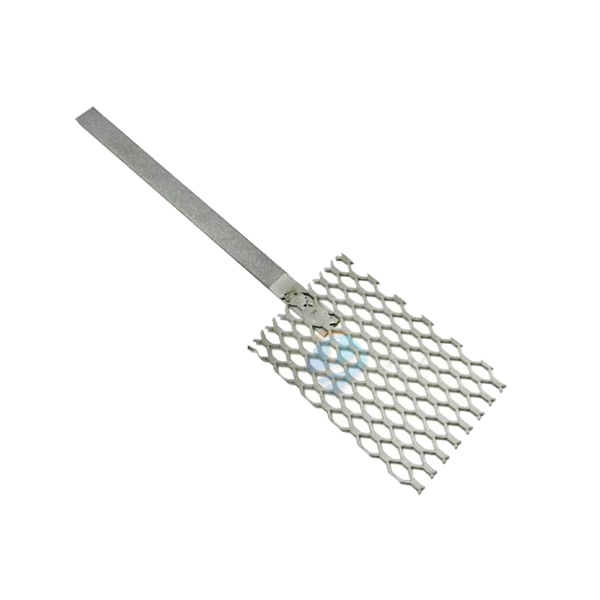

titanium electrode for electrolysis

Effective overpotential

Reusable

Excellent current density and production capacity

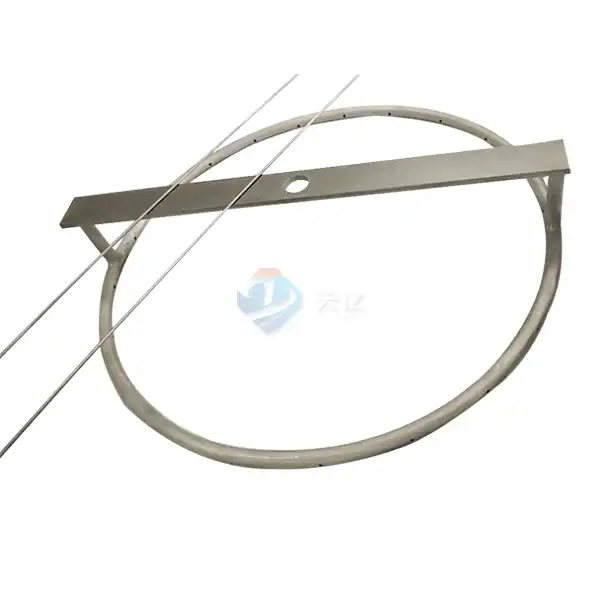

Customizable geometry of oxide-coated titanium anodes

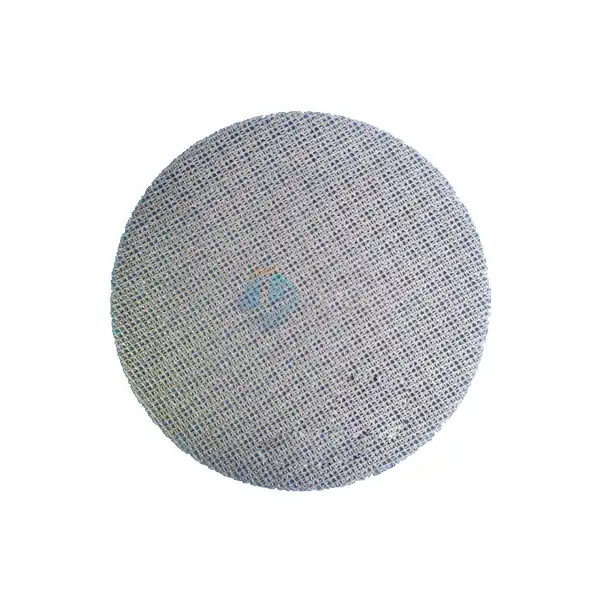

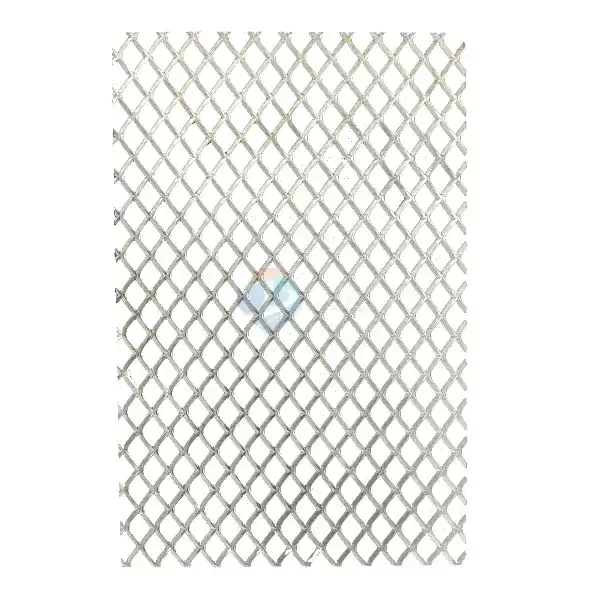

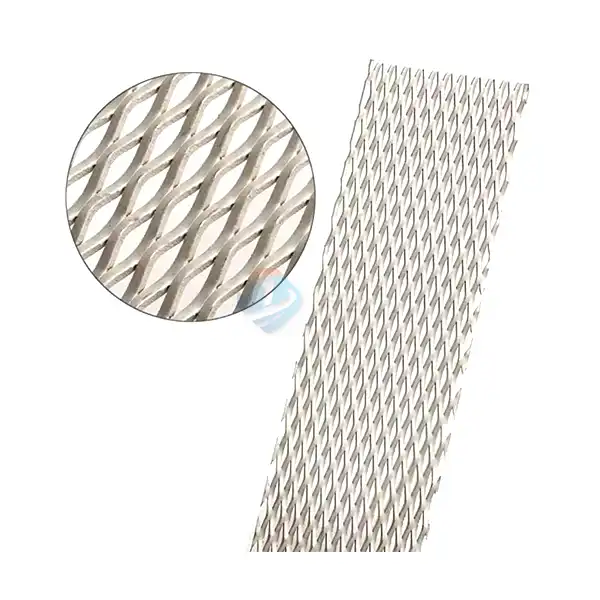

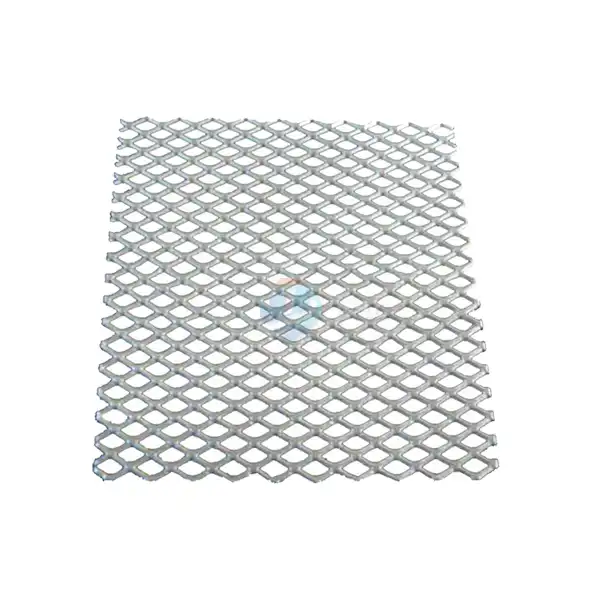

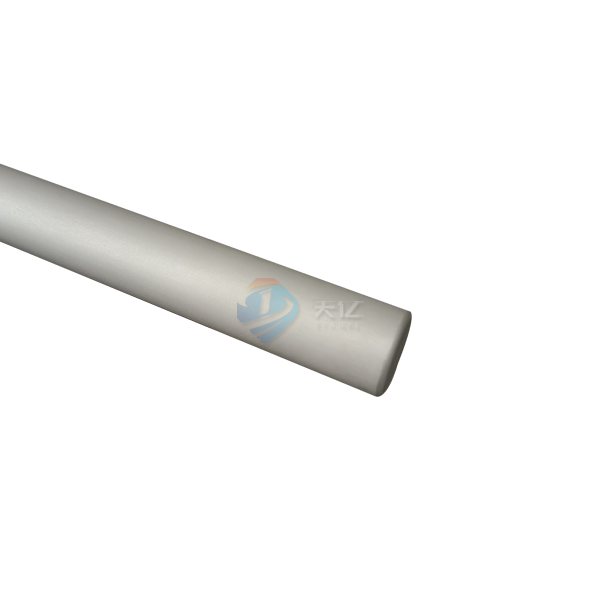

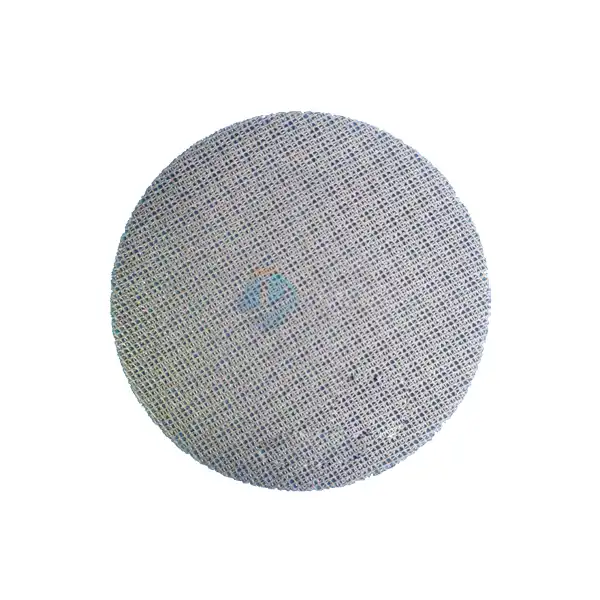

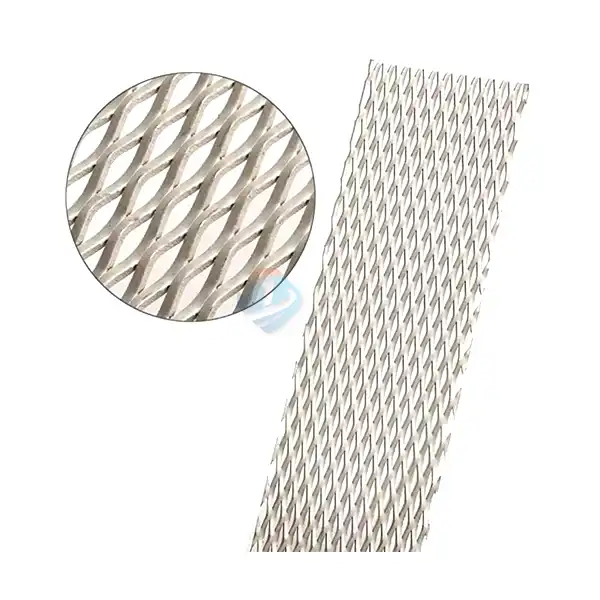

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Titanium Electrode for Electrolysis Introduction

Titanium electrode for electrolysis is often used in electrolysis due to their unique properties. However, titanium itself isn't the active component. It's usually coated with a thin layer of precious metal oxides like ruthenium oxide (RuO2) or iridium oxide (IrO2). This combination is called a Mixed Metal Oxide (MMO) electrode.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

Our titanium electrode for electrolysis are made from high-quality titanium alloys, ensuring excellent corrosion resistance and durability. The MMO coating enhances the electrode's performance, facilitating efficient electron transfer and improving overall electrolysis efficiency. The electrodes are designed to withstand harsh conditions, making them ideal for various industrial applications.

The MMO coating significantly enhances the electrode's performance by facilitating efficient electron transfer and improving the overall efficiency of electrolysis. This advanced coating is designed to endure harsh conditions, which makes the electrodes highly suitable for a variety of industrial applications where durability and reliability are essential.

Product Advantages

- Corrosion Resistance: Titanium's inherent resistance to corrosion ensures a long lifespan in challenging environments.

- High Conductivity: The MMO coating provides superior electrical conductivity, enhancing the efficiency of electrochemical reactions.

- Customizability: We offer customizable sizes and coatings tailored to meet your specific application needs.

Technical Features

Our titanium electrodes are engineered to provide:

- Low Overpotential: Reducing energy consumption during electrolysis.

- High Stability: Maintaining performance over extended operational periods.

- Eco-Friendly Design: Supporting sustainable practices in industrial applications.

Product Application

The titanium electrode for electrolysis is versatile and used in:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Quality Inspection

Quality is our priority. Each batch of titanium electrode for electrolysis. undergoes stringent quality checks, including:

- Material Testing: Ensuring the integrity and performance of raw materials.

- Coating Verification: Assessing the thickness and adherence of coatings.

- Final Product Testing: Evaluating electrical performance and durability.

Packaging Method

Our packaging is designed to protect your electrodes during transit. We use:

- Custom Packaging Solutions: Tailored to fit the product dimensions.

- Moisture-Proof Materials: Ensuring safe delivery even in humid conditions.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We provide OEM services to meet the unique needs of our partners, offering:

- Custom designs and specifications.

- Tailored branding options.

- Flexible production quantities.

FAQ

Q: What industries use titanium electrodes for electrolysis?

A: Our titanium electrode for electrolysis are widely used in water treatment, electroplating, cathodic protection, and hydrogen production.

Q: How do I determine the right electrode for my application?

A: Our team can assist you in selecting the most suitable electrode based on your specific requirements.

Q: Are there customization options available?

A: Yes, we offer fully customizable electrodes to meet individual client specifications.

Contact Us

For more information or to discuss your specific needs, please contact us at [info@di-nol.com]. Our dedicated team is here to provide you with tailored solutions and support.