platinum coated titanium anode

Effective overpotential

Reusable

Excellent current density and production capacity

Customizable geometry of oxide-coated titanium anodes

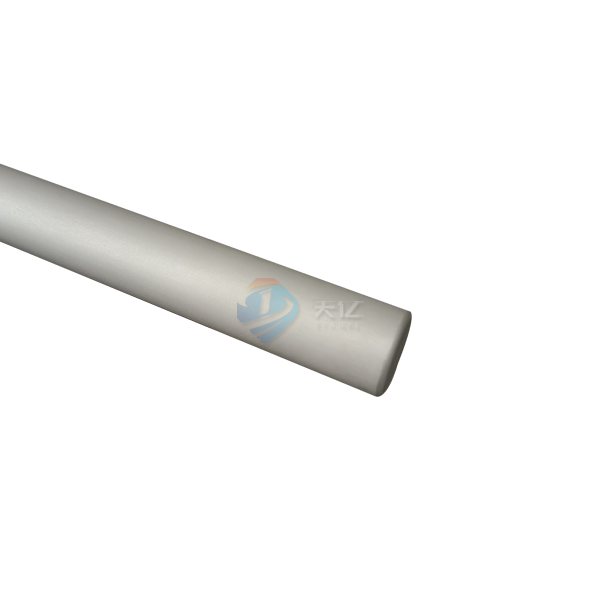

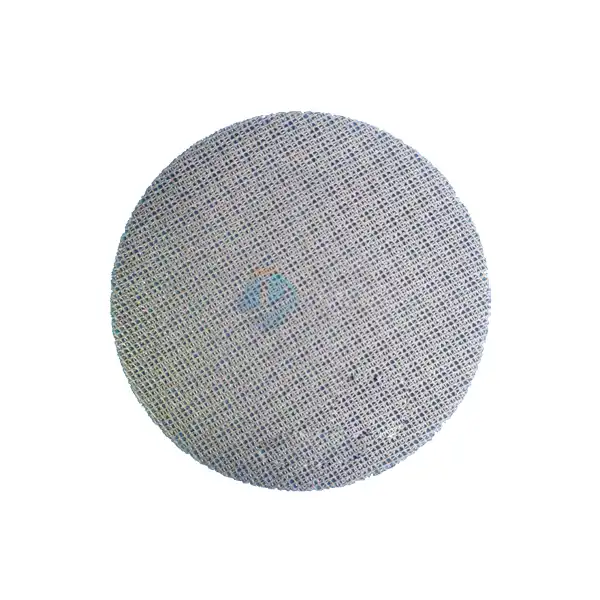

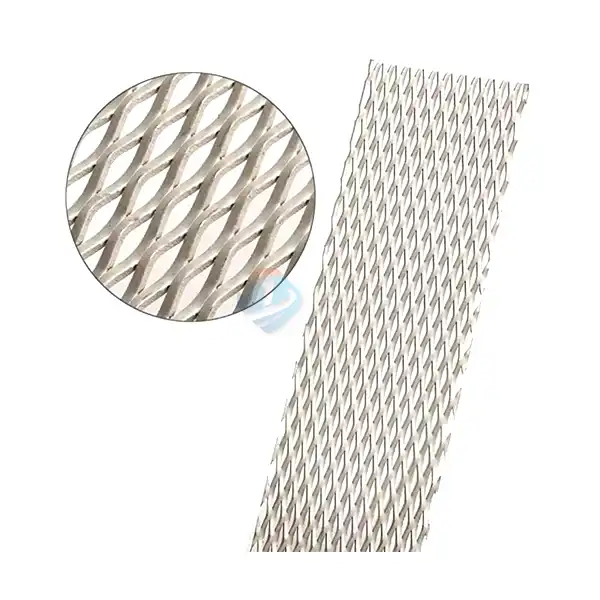

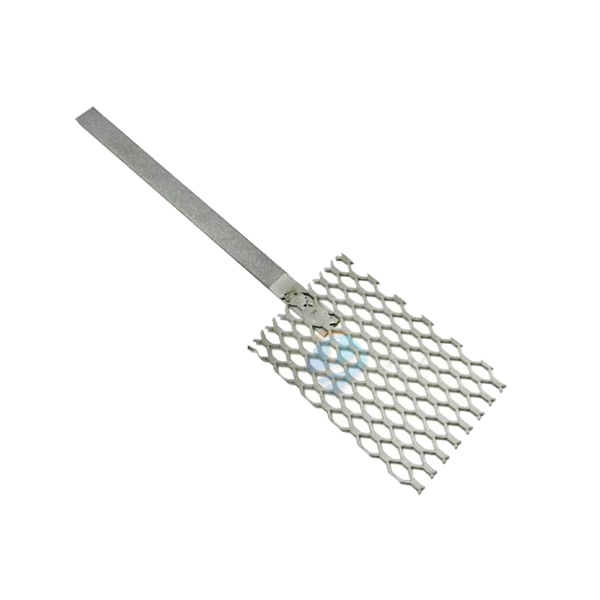

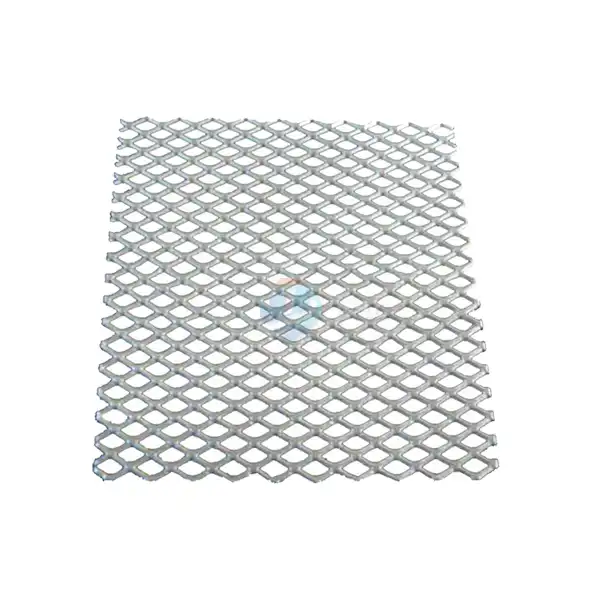

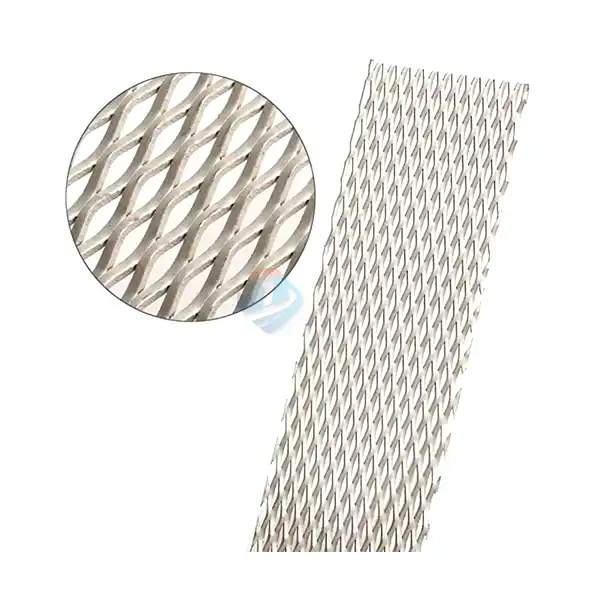

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Platinum Coated Titanium Anode Introduction

Looking for reliable, high-performance anodes? TianYi’s Platinum Coated Titanium Anodes deliver outstanding results. Our anodes are made with top-quality materials and a precise manufacturing process, ensuring longer service life and better conductivity. We use a special coating technique that guarantees a uniform platinum layer, leading to higher efficiency and lower energy costs. This translates to significant savings for your operations. Choose TianYi for anodes that consistently perform under demanding conditions, reducing downtime and boosting your productivity. With TianYi, you get not just a product, but a partner dedicated to your success.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

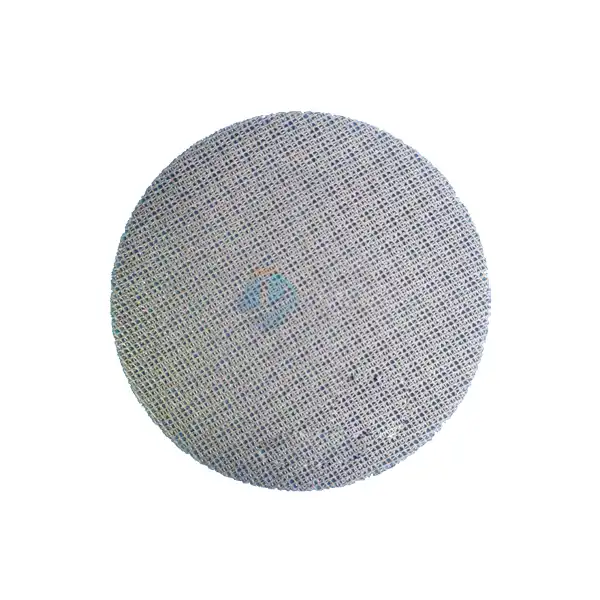

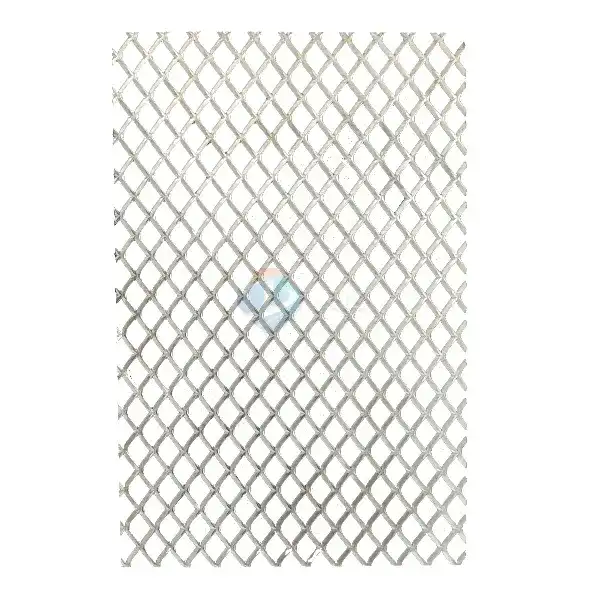

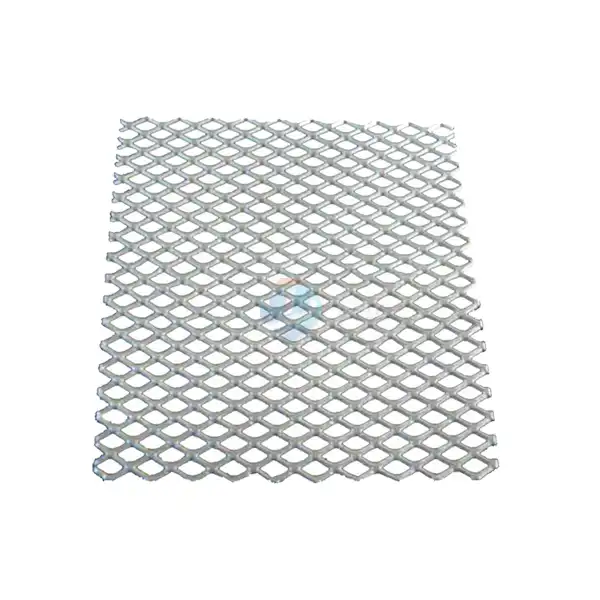

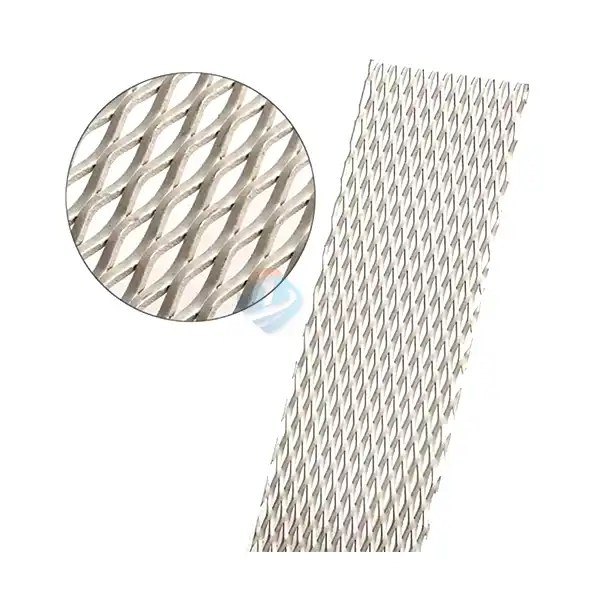

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

The platinum coated titanium anode is composed of a titanium substrate coated with a thin layer of platinum. This design ensures excellent conductivity and corrosion resistance, providing reliable performance in harsh electrochemical environments. The combination of titanium’s lightweight properties and platinum’s durability enhances the anode's efficiency, making it suitable for a wide range of applications.

Product Advantages

- High Corrosion Resistance: The platinum coating provides exceptional resistance to corrosion, ensuring a long lifespan in various electrolytic environments.

- Enhanced Conductivity: The conductive properties of platinum improve the overall efficiency of the anode, reducing energy costs.

- Customizable Options: We offer customizable designs to meet specific client requirements, ensuring that our anodes fit seamlessly into existing systems.

- Environmental Compliance: Our products are designed with sustainability in mind, promoting eco-friendly operations.

Technical Features

- Durable Coating: The platinum layer is applied using advanced techniques to ensure uniformity and longevity.

- Versatile Applications: Suitable for use in electroplating, water treatment, and cathodic protection systems.

- Easy Installation: Designed for straightforward integration into various systems without requiring extensive modifications.

Platinum Coated Titanium Anode Application

Our platinum coated titanium anode is widely used in:

Chlor-alkali production: Efficient electrolysis of brine for chlorine, caustic soda, and hydrogen generation

Manganese dioxide electrolysis: High-performance anode for producing electrolytic manganese dioxide (EMD)

Metal surface treatment: Electroplating, anodizing, and electrophoretic deposition processes

Printed circuit board (PCB) manufacturing: Copper electroplating and via filling applications

Water treatment: Electrolytic water disinfection and oxidation processes

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process emphasizes precision and quality:

Titanium Substrate Preparation: Selecting high-quality titanium and cutting it to the desired shape and size.

Surface Treatment: Cleaning and preparing the titanium surface to ensure strong platinum adhesion.

Platinum Coating: Applying a precise layer of platinum using advanced coating techniques.

Heat Treatment: Fusing the platinum coating to the titanium substrate for enhanced durability.

Quality Inspection: Rigorous testing for coating thickness, uniformity, and performance.

Packaging and Shipping: Secure packaging to ensure safe delivery to our customers.

Packaging Method

We utilize custom packaging solutions designed to protect the integrity of the products during transit. Our packaging methods ensure safe delivery worldwide, minimizing any risk of damage. electrodes with MMO coatings are also used in other types of electrochemical advanced oxidation processes (EAOPs) for the treatment of organic wastewater. These processes rely on the generation of strong oxidizing agents like hydroxyl radicals to break down contaminants, and the MMO coating can enhance the electrodes' ability to generate these radicals efficiently .

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer extensive OEM services, providing tailored solutions to meet the unique needs of our clients. From custom sizes to specific coatings, our team is dedicated to fulfilling your requirements with precision. These processes rely on the generation of strong oxidizing agents like hydroxyl radicals to break down contaminants, and the MMO coating can enhance the electrodes' ability to generate these radicals efficiently .

FAQ

Q: What is the lifespan of a product?

A: With proper maintenance and usage, our anodes can last for several years, depending on operating conditions.

Q: Can the anodes be customized?

A: Yes, we provide fully customizable options to meet specific application requirements.

Q: Are the products environmentally friendly?

A: Absolutely! Our anodes are designed with sustainability in mind, promoting eco-friendly practices.

Contact Us

For more information about our platinum coated titanium anodes or to discuss your specific needs, please contact us at [info@di-nol.com]. Our team is here to assist you in finding the right solutions for your electrochemical applications.

YOU MAY LIKE

VIEW MOREPlatinum-titanium anode

VIEW MOREPlatinum-titanium anode VIEW MOREgrade 1 titanium electrode

VIEW MOREgrade 1 titanium electrode VIEW MOREelectroplating titanium electrode

VIEW MOREelectroplating titanium electrode VIEW MOREelectrolysis titanium electrode

VIEW MOREelectrolysis titanium electrode VIEW MORETitanium Electrodes for Water Ionization

VIEW MORETitanium Electrodes for Water Ionization VIEW MOREelectrode anode titanium

VIEW MOREelectrode anode titanium VIEW MOREtitanium electrode for electrolysis

VIEW MOREtitanium electrode for electrolysis VIEW MOREtitanium electrode

VIEW MOREtitanium electrode