electrode anode titanium

Effective overpotential

Reusable

Excellent current density and production capacity

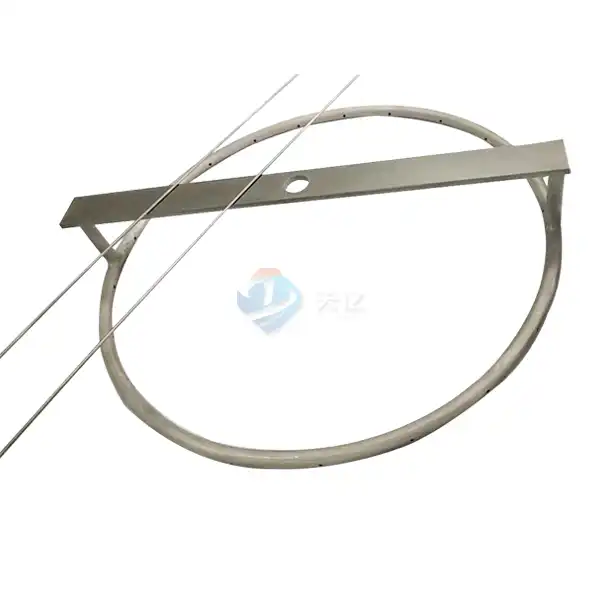

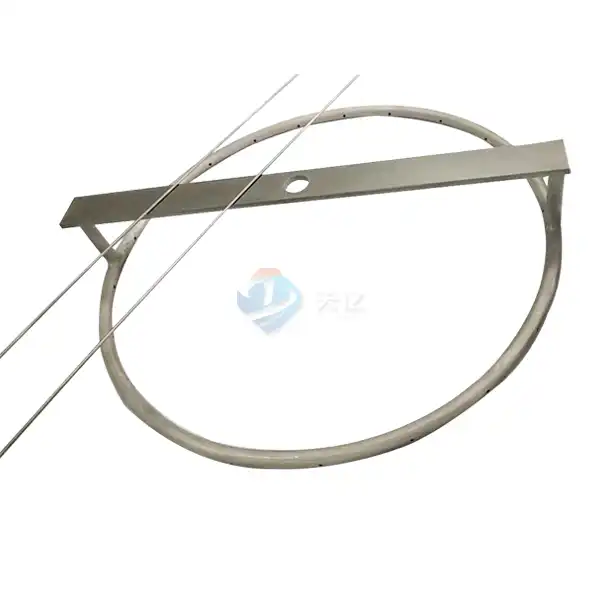

Customizable geometry of oxide-coated titanium anodes

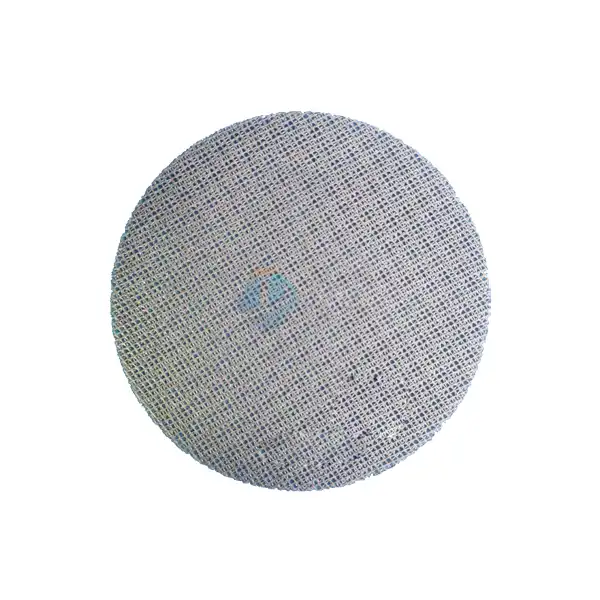

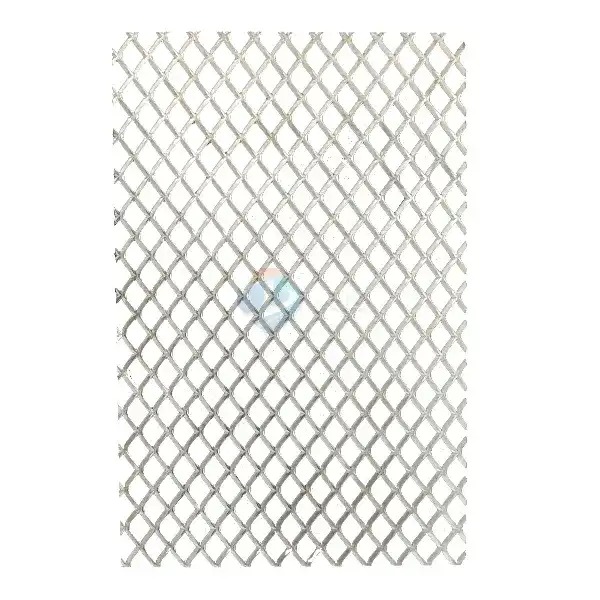

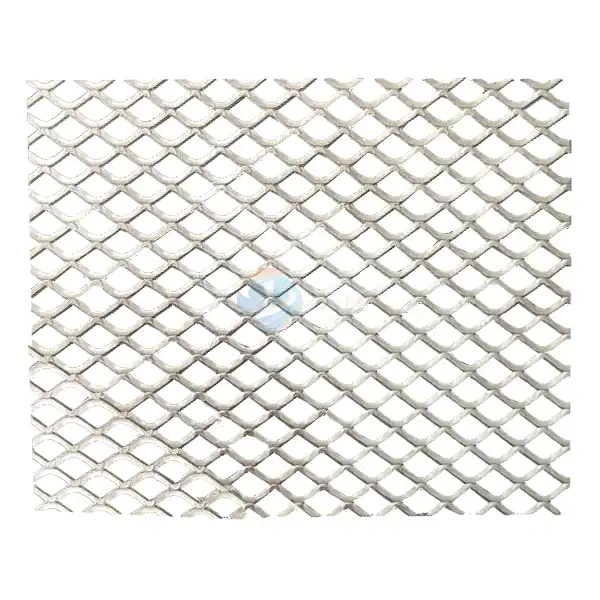

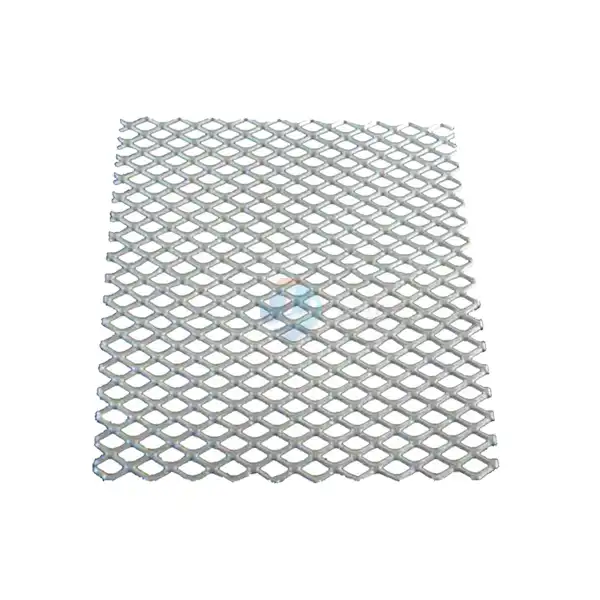

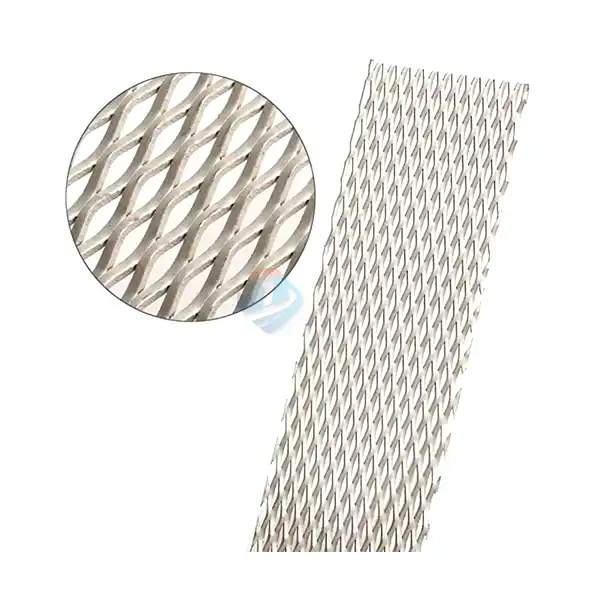

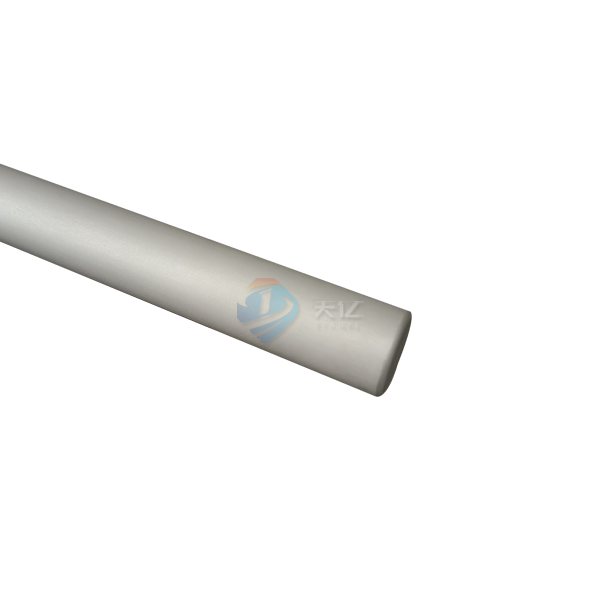

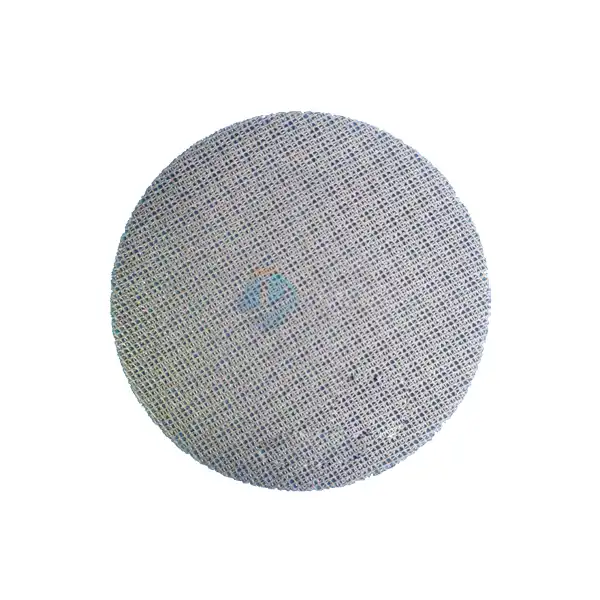

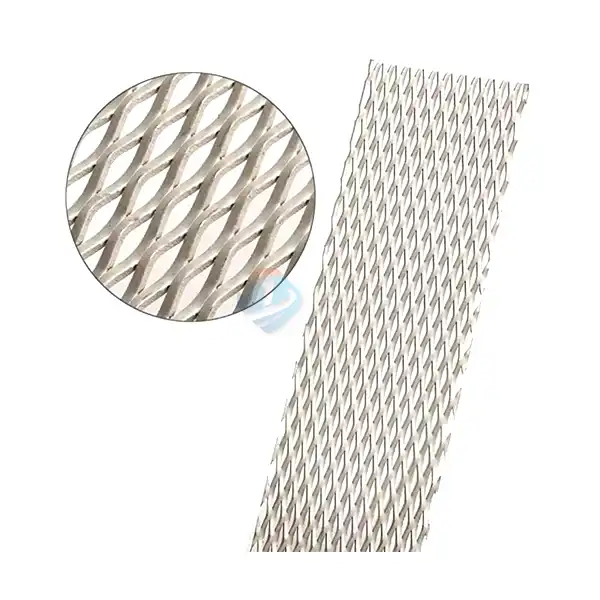

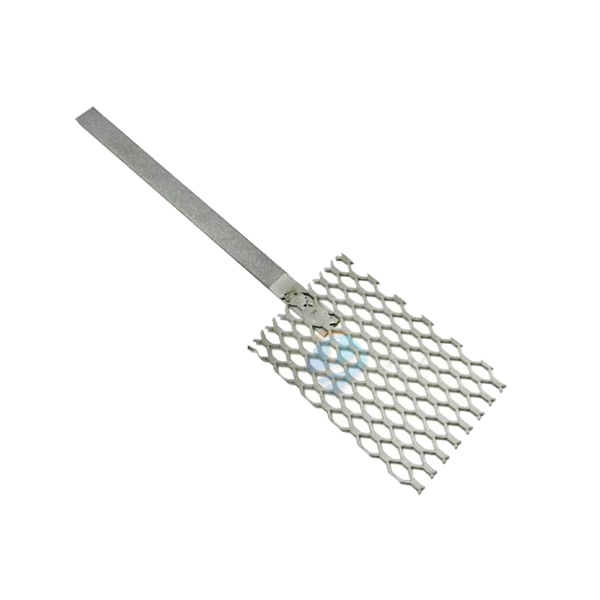

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Electrode Anode Titanium Introduction

We specialize in advanced electrode anode titanium, particularly our high-performance MMO (Mixed Metal Oxide) coated titanium anodes. Our products are essential for a variety of applications, including water treatment, electroplating, and hydrogen production through water electrolysis. With a focus on innovation and sustainability, we provide top-quality anodes designed for efficiency and durability.

Product Specifications

Description | Platinized Titanium Anode |

pH level | Between 1 and 12 |

Platinum layer thickness | 0.1 - 20 µm or as desired |

Maximum content of fluorides in electrolyte | 50 mg/l |

Maximum allowable current | 75 A/dm2 |

Maximum allowable operating voltage | 12 |

Consumption rate in sea water | 8 ~ 16 mg / A year |

Shape available | Plate, mesh, rod, tubular, wire etc. |

|  |  |

|  |  |

|  |

Product Composition and Design

Our electrode anode titanium products are made from high-grade titanium alloys, ensuring excellent corrosion resistance and strength. The MMO coating enhances the anode's performance by providing a stable, low-impedance interface for electrochemical reactions. This design optimizes the anodes for various industrial applications, contributing to longer service life and reduced maintenance costs.

Product Advantages

- High Durability: Our anodes are engineered to withstand harsh environments, ensuring longevity and reliability.

- Customizable Solutions: We offer tailored solutions to meet specific client requirements, ensuring optimal performance for every application.

- Environmental Compliance: Our products adhere to strict environmental standards, promoting sustainable practices across industries.

Technical Features

- Low Overpotential: Reduces energy consumption during electrochemical processes.

- Corrosion Resistance: Extended lifespan due to superior resistance to electrochemical corrosion.

- Flexible Design Options: Available in various sizes and coatings to suit specific applications.

Product Application

Our electrode anode titanium products are widely used in:

1. Horizontal plating, pulse plating;

2. Precious metal plating - such as gold, platinum, palladium, rhodium and ruthenium plating solutions;

3. Non-ferrous metal plating - such as nickel, copper, tin, zinc and non-fluoride chromium plating solutions;

4. Printed circuit board plating;

5. Impressed current cathodic protection.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process employs advanced manufacturing techniques to ensure the highest quality:

Material Selection

The production process starts with sourcing high-purity titanium, chosen for its excellent corrosion resistance and structural integrity. This ensures the anode can withstand harsh electrochemical environments.

Initial Surface Cleaning

The titanium raw material is thoroughly cleaned using solvents and ultrasonic baths to remove surface contaminants, including oils and dust, which could interfere with subsequent processing steps.

Surface Texturing

To improve coating adhesion, the titanium surface is textured through methods such as sandblasting or acid etching. This roughening creates microstructures that enhance the bond between the titanium and the coating.

Coating Material Preparation

A coating mixture is prepared, typically consisting of precious metals like iridium or ruthenium oxides, combined with titanium oxide. The formulation is designed to optimize the electrochemical activity of the anode.

Coating Application

The coating is applied to the titanium substrate using techniques such as thermal spraying, sputtering, or electroplating. This step ensures even coverage and proper thickness, which are critical for performance.

Quality Inspection

Quality is our top priority. Every batch of electrode anode titanium undergoes comprehensive testing, including:

- Dimensional Inspection: Verifying that all products meet specified dimensions.

- Coating Thickness Measurement: Ensuring the coating is applied uniformly.

- Performance Testing: Assessing electrochemical properties to confirm efficiency.

Packaging Method

We prioritize safe and efficient packaging to protect our products during transit. Our methods include:

- Custom Packaging Solutions: Designed to fit the product specifications, ensuring minimal movement during transport.

- Eco-friendly Materials: We use sustainable packaging materials whenever possible.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services to meet your unique requirements:

- Custom Designs: Tailored products that align with your specifications.

- Collaborative Development: Working closely with clients to innovate and create effective solutions.

FAQ

Q: What is the typical lifespan of your anodes?

A: Our anodes generally last between 5 to 10 years, depending on usage conditions.

Q: Can you customize the dimensions of the anodes?

A: Yes, we provide fully customizable solutions based on client requirements.

Q: What industries do you serve?

A: We cater to a broad range of industries, including water treatment, mining, and electroplating.

Q: Are your products environmentally friendly?

A: Absolutely! We are committed to sustainable practices and environmentally compliant products.

Q: How can I request a quote?

A: You can contact us at info@di-nol.com for any inquiries or to request a quote.

Contact Us

At Shaanxi Tianyi, we are dedicated to providing superior electrode anode titanium solutions tailored to your needs. For more information or to discuss your specific requirements, please reach out to us at info@di-nol.com. Let us help you achieve your electrochemical goals with our innovative products!