electroplating titanium electrode

Effective overpotential

Reusable

Excellent current density and production capacity

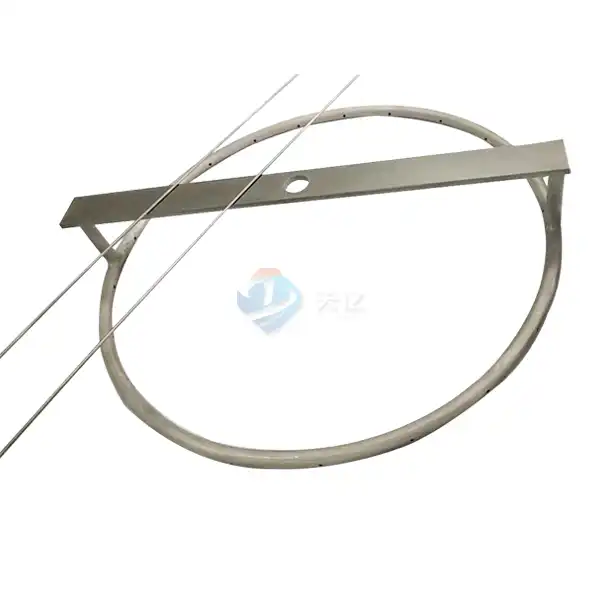

Customizable geometry of oxide-coated titanium anodes

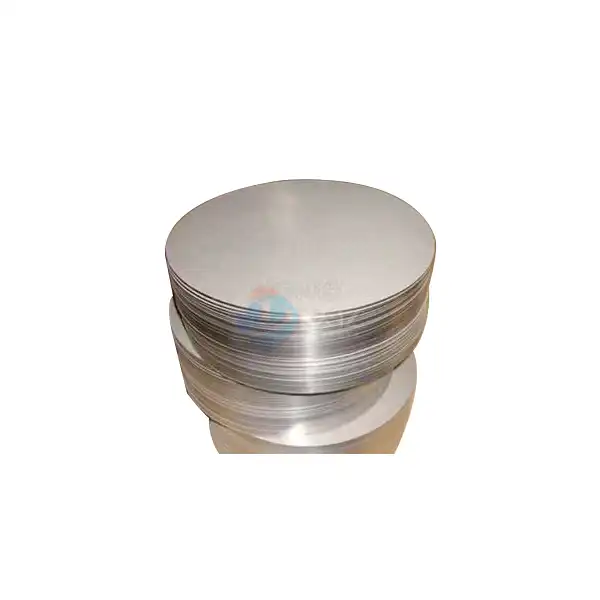

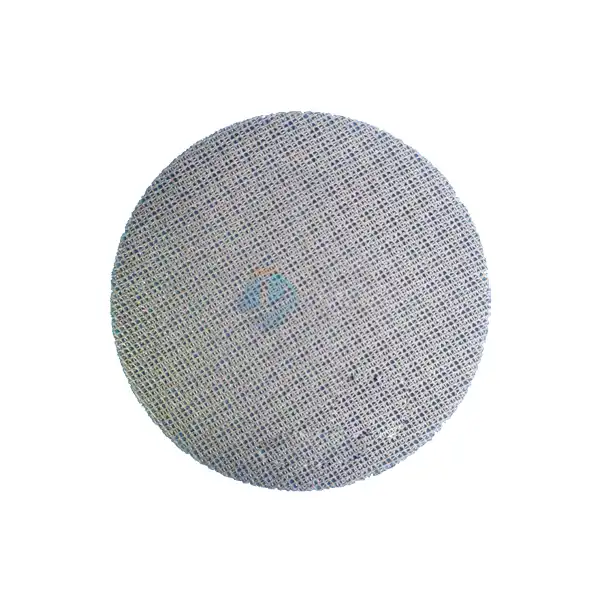

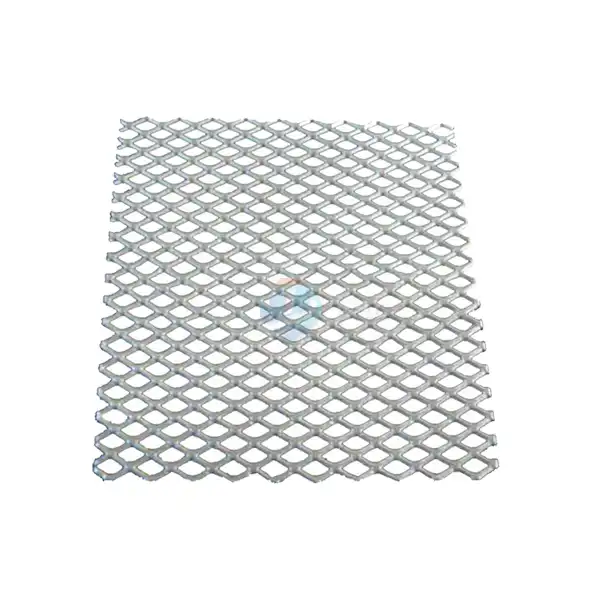

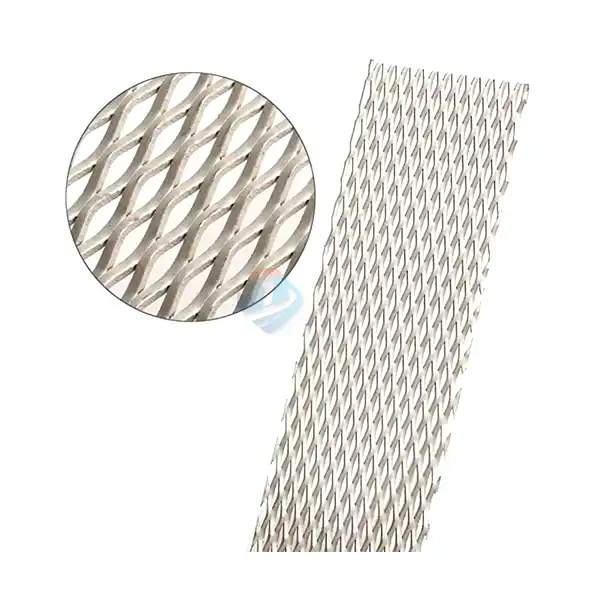

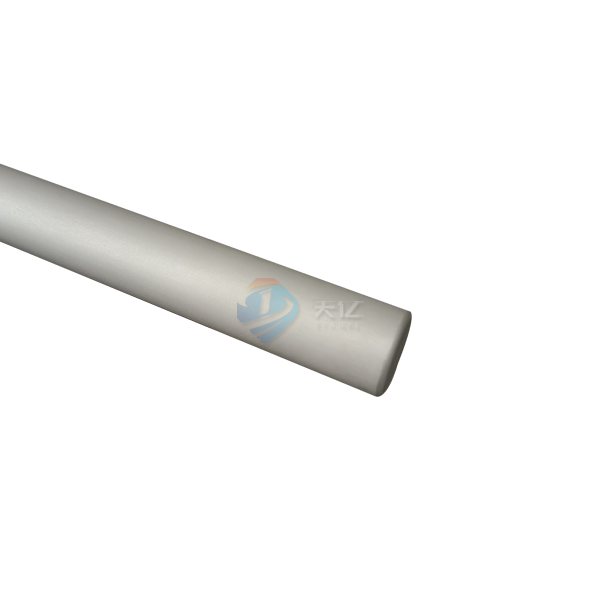

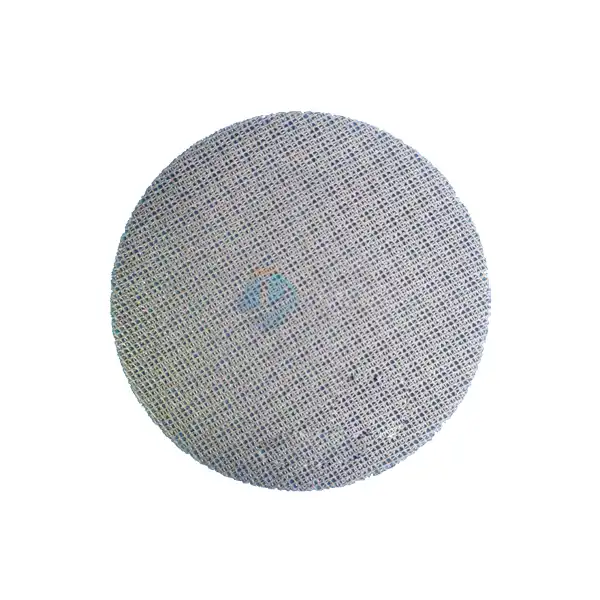

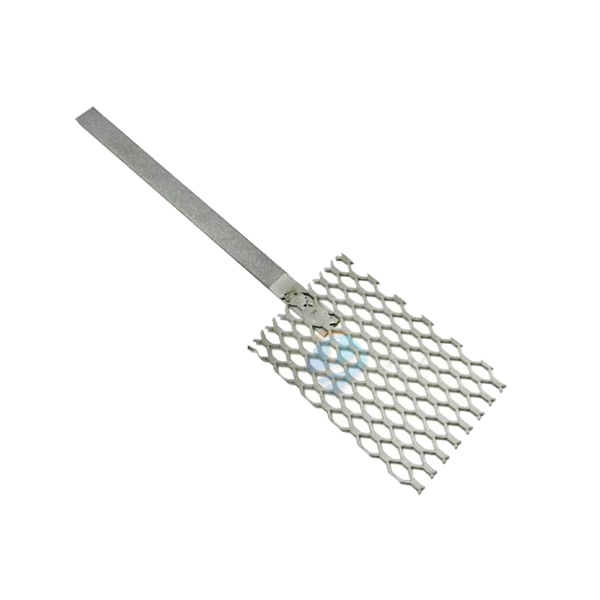

Variety of sizes for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to the future of electroplating with our electroplating titanium electrode. Designed for superior performance and durability, these electrodes are crucial in a variety of applications, including industrial electroplating, cathodic protection, and water treatment. Our titanium electrodes, coated with advanced MMO (Mixed Metal Oxide) technology, ensure excellent efficiency and longevity, making them the preferred choice for businesses looking to enhance their electrochemical processes.

Product Specifications

| Parameter | Specification |

|---|---|

| Material | Titanium (Grade 1, Grade 2, or Customized) |

| Coating Type | Platinum, Mixed Metal Oxide (MMO), Ruthenium-Iridium, etc. |

| Coating Thickness | 1-10 μm (Adjustable based on application) |

| Surface Roughness (Ra) | ≤ 0.2 μm |

| Electrode Shape | Plate, Rod, Mesh, or Customizable |

| Dimensions | Customizable (Based on application) |

| Operating Current Density | 50-500 A/m² |

| Service Life | 1-5 Years (Varies with Coating and Use) |

| Operating Temperature Range | Up to 80°C |

| Application | Metal Finishing, Electroplating Baths, etc. |

| pH Range | 0-14 (Depending on Coating) |

| Certification | ISO 9001, CE, RoHS (if applicable) |

|  |  |

|  |  |

|  |

Product Composition and Design

Our electroplating titanium electrodes are crafted from high-grade titanium alloys, ensuring exceptional strength and corrosion resistance. The MMO coating is applied using advanced electrochemical deposition techniques, resulting in a uniform and durable layer that enhances performance in harsh environments. Each electrode is designed for easy installation and maintenance, making them user-friendly for various industrial settings.

Product Advantages

- Corrosion Resistance: Titanium's inherent resistance to corrosion ensures a longer lifespan, reducing the frequency of replacements.

- High Efficiency: The MMO coating enhances electrochemical performance, providing faster and more efficient plating processes.

- Customization: We offer tailored solutions to meet the specific needs of your application, including size and coating options.

- Sustainability: Our manufacturing processes are environmentally friendly, reflecting our commitment to sustainability and responsible production practices.

Technical Features

- Low Overpotential: Our electrodes exhibit low overpotential, minimizing energy consumption during operation.

- Thermal Stability: Designed to withstand high temperatures, ensuring consistent performance under varying conditions.

- Electrical Conductivity: Excellent conductivity allows for improved current distribution, optimizing plating quality.

Product Application

Our electroplating titanium electrodes are widely used in:

- Industrial Electroplating: Enhancing the quality and durability of metal coatings.

- Water Treatment: Effective in disinfection and purification processes.

- Cathodic Protection: Preventing corrosion in pipelines and storage tanks.

- Hydrometallurgy: Used in extracting metals from ores efficiently.

Be used in a wide range of industries.

Water treatment

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

At Shaanxi Tianyi, we utilize state-of-the-art production facilities to manufacture our electrodes. The process includes:

Raw Material Selection

The process begins with selecting high-purity titanium, recognized for its outstanding corrosion resistance and mechanical properties, making it an ideal substrate for electroplating applications.

Surface Cleaning

Titanium substrates undergo a thorough cleaning process to remove any contaminants. This involves using alkaline solutions and ultrasonic cleaning to ensure the surfaces are free from oils, dirt, and other residues.

Surface Activation

After cleaning, the titanium surface is activated to enhance the adhesion of the electroplated layer. This is typically achieved through acid etching, which creates a micro-roughened surface.

Electroplating Solution Preparation

A specific electroplating bath is prepared, usually containing metal salts such as nickel, copper, or gold, along with additives to improve the quality of the deposited layer. The bath composition is tailored to achieve desired properties.

Electroplating Process

The titanium substrate is immersed in the electroplating solution, and an electrical current is applied. This causes metal ions to deposit onto the titanium surface, forming a uniform coating.

Coating Thickness Monitoring

During electroplating, the thickness of the deposited layer is continuously monitored to ensure it meets specifications. Adjustments to current density and plating time are made as necessary to achieve the desired coating thickness.

Post-Treatment Process

Once electroplating is complete, the coated electrodes undergo a post-treatment process, which may include rinsing, drying, and additional curing steps to enhance coating durability and adhesion.

Electrochemical Testing

Each titanium electrode is subjected to rigorous electrochemical testing to evaluate its performance in various conditions. Parameters such as conductivity, corrosion resistance, and overall efficiency are assessed.

Quality Control and Packaging

Final inspections are conducted to ensure the quality of the electroplated titanium electrodes, followed by careful packaging to protect them during transport. Documentation is provided, including specifications and handling instructions for users.

Quality Inspection

Quality is our top priority. Each electroplating titanium electrodes undergoes rigorous testing to ensure it meets industry standards for performance and durability. This includes:

- Dimensional Checks: Ensuring specifications are met.

- Coating Thickness Testing: Verifying uniformity and adherence.

- Performance Testing: Evaluating efficiency and effectiveness in real-world applications.

Packaging Method

Our electrodes are packaged with care to ensure safe delivery. We use:

- Custom Packaging Solutions: Tailored to protect products during transit.

- Eco-Friendly Materials: Commitment to sustainability in our packaging choices.

- Clear Labeling: Ensuring easy identification and handling.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, providing custom solutions that cater to your unique needs. From tailored electrode designs to specific packaging requirements, our team is equipped to meet diverse customer demands, ensuring high performance and satisfaction.

FAQ

1. Q:What is an electroplating titanium electrode?

A:An product is a component used in electrochemical processes, typically coated with MMO to enhance performance and durability in applications like plating and water treatment.

2. Q:How long do these electrodes last?

A:With proper care, our titanium electrodes can last up to 15 years, depending on the application and environmental conditions.

3.Q: Can I customize the size of the electrode?

A: Yes, we offer customizable lengths and thicknesses to meet your specific application needs.

4. Q:Are these electrodes environmentally friendly?

A: Yes, our manufacturing processes prioritize sustainability and eco-friendly practices.

5. Q:How do I place an order?

A: You can contact us directly at [info@di-nol.com] for inquiries and order placement.

Contact Us

Ready to enhance your electrochemical processes with our high-performance products? For more information or to place an order, please reach out to us at [info@di-nol.com]. Our dedicated team is here to assist you with any questions or custom requests you may have.