Flexible Linear Anodes

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Flexible Linear Anodes Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., where we specialize in the development and production of cutting-edge electrochemical materials. Our Flexible Linear Anodes are designed for a variety of industrial applications, offering superior performance and reliability. These anodes are crafted to meet the demands of modern electrochemical processes, ensuring efficient operation in diverse environments.

Product Specifications

Product Model | ELTA-15 (MMO coated φ1.5mm titanium wire anode) | ELTA-30 (MMO coated φ3.0mm anode wire) |

Outer diameter of combined flexible anode | 38 | 38 |

MMO/Ti anode core diameter | 1.5mm | 3.0mm |

Output Current | 300~1000mAm | 300~1000mAm |

Design life | ≥40 years, can be designed according to user requirements | ≥40 years, can be designed according to user requirements |

cable | 1×10mm2XLPE/PVC | 1×10mm2XLPE/PVC |

Filling toner carbon content | ≥99.5% | ≥99.5% |

Contact resistance between MMO/Ti wire and cable | ≤0.0009Ω | ≤0.0009Ω |

Anode weight | 1.5Kg/m | 1.5Kg/m |

Length of anode per roll | 500m, 1000m (can be cut to length freely) | 500m, 1000m (can be cut to length freely) |

|  |  |

|  |  |

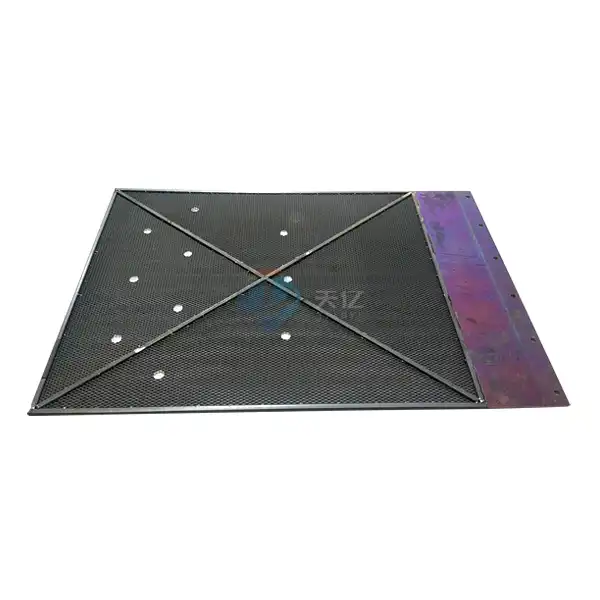

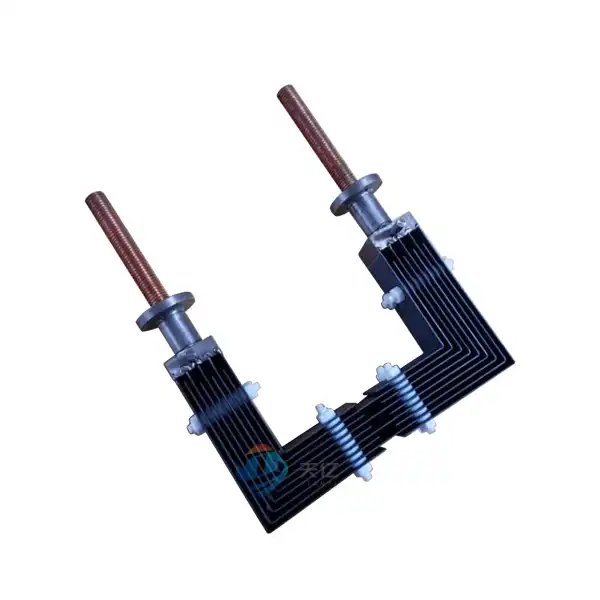

Product Composition and Design

Our Flexible Linear Anodes feature a robust design made from high-quality titanium alloy, coated with advanced MMO technology. This composition ensures exceptional corrosion resistance and durability, making them ideal for both demanding industrial applications and everyday use. The flexible nature of these anodes allows for easy installation and adaptation to various electrochemical systems.

Product Advantages

- High Durability: Designed to withstand harsh environments, our anodes exhibit exceptional longevity and reliability.

- Customizable Sizes: We provide flexible solutions tailored to your specific needs, ensuring optimal performance in your applications.

- Environmentally Friendly: Our anodes are manufactured with eco-friendly materials, aligning with sustainable practices.

- Enhanced Performance: The MMO coating technology significantly improves current efficiency, leading to lower operational costs.

Technical Features

- Excellent Conductivity: Enhanced electrical conductivity for improved electrochemical reactions.

- Corrosion Resistance: Special coatings that protect against corrosive elements in various environments.

- Versatile Applications: Suitable for a range of uses, from water treatment to industrial electroplating.

Product Application

Our Flexible Linear Anodes are perfect for various applications, including:

1. Old pipelines with aging cover layers;

2. Intricate pipe networks;

3. The outer wall of the bottom of storage tanks;

4. Long-distance, small-pitch parallel pipelines;

5. High resistivity environment;

6. Cathodic protection of the outer surface of the bottom plate of steel storage tanks;

7. Construction site of storage tank cathodic protection project.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

We follow a meticulous production process that includes:

Material Selection

The production of flexible linear anodes begins with selecting high-quality conductive materials. Common choices include advanced polymers infused with conductive fillers or metal coatings, ensuring flexibility and excellent electrical conductivity, which are essential for various electrochemical applications.

Polymer Formulation

The selected polymer is subjected to a formulation process where it is mixed with conductive additives, plasticizers, and stabilizers. This step is crucial to enhance the anode's flexibility, mechanical strength, and resistance to environmental factors.

Extrusion Process

The formulated material is then processed through an extrusion method. During extrusion, the polymer mixture is heated and forced through a die to create a continuous linear shape. This allows for the customization of dimensions to fit specific application requirements.

Cooling and Cutting

After extrusion, the linear anodes are cooled to solidify the material. Once cooled, they are cut to the desired lengths. This process can be adjusted to produce various sizes based on customer specifications or application needs.

Conductive Coating Application

A conductive coating is applied to the surface of the linear anodes to enhance their electrochemical properties. This may involve techniques such as spray coating, dip coating, or the application of conductive inks. The goal is to ensure uniform coverage for optimal performance.

Curing Process

The coated anodes undergo a curing process to solidify the conductive layer and improve adhesion to the polymer substrate. This is typically achieved through heat treatment or chemical curing agents, ensuring the durability of the coating during operation.

Quality Control Testing

Each batch of flexible linear anodes is rigorously tested to ensure they meet quality standards. This includes evaluations of electrical conductivity, mechanical flexibility, and adherence of the conductive coating. Any defects are identified and addressed before final approval.

Final Inspection

Following quality control, the anodes undergo a final inspection to verify dimensions, surface quality, and overall performance. This ensures that the products meet the high standards expected by customers.

Packaging

Once inspected, the flexible linear anodes are carefully packaged to prevent damage during transportation. The packaging process includes protective materials to ensure the integrity of the products.

Documentation

Each package includes documentation detailing product specifications, application guidelines, and safety instructions. This information helps customers effectively utilize the flexible linear anodes in their respective applications.

This systematic approach to the production of flexible linear anodes ensures high-quality, reliable products suitable for various electrochemical processes, including water treatment, electrolysis, and more.

Quality Inspection

At Shaanxi Tianyi, we prioritize quality. Each batch of Flexible Linear Anodes undergoes comprehensive quality inspections, including:

- Raw material verification

- Dimensional accuracy checks

- Coating thickness measurement

- Performance testing in simulated conditions

Packaging Method

We use secure and efficient packaging methods to ensure that our products arrive safely. Our packaging includes:

- Custom-sized boxes to prevent damage

- Moisture-proof materials to protect against environmental factors

- Clear labeling for easy identification

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services to meet the unique requirements of our partners. Whether you need custom sizes, coatings, or packaging, our team is equipped to deliver tailored solutions that align with your needs.

FAQ

Q1: What are products used for?

A: They are primarily used in water treatment, electroplating, and cathodic protection applications.

Q2: How long do these anodes last?

A: With proper maintenance, they can last up to 10 years.

Q3: Can I get custom sizes?

A: Yes, we provide fully customizable solutions to meet your specific requirements.

Q4: What is the coating material?

A: Our anodes are coated with Mixed Metal Oxide (MMO) for enhanced performance.

Q5: Do you provide after-sales support?

A: Yes, we offer comprehensive after-sales support, including maintenance and product replacements.

Contact Us

For more information about our Flexible Linear Anodes or to discuss your specific needs, please reach out to us at info@di-nol.com. Our team is ready to assist you with any questions or inquiries you may have.

By choosing Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., you are partnering with a leader in the electrochemical industry. Our commitment to quality and innovation ensures that you receive products that meet the highest standards, helping your business thrive.

YOU MAY LIKE

VIEW MOREPolymer flexible anode

VIEW MOREPolymer flexible anode VIEW MORELead oxide electrode

VIEW MORELead oxide electrode VIEW MOREMMO/Ti Linear Anode

VIEW MOREMMO/Ti Linear Anode VIEW MOREMMO Ribbon Anode

VIEW MOREMMO Ribbon Anode VIEW MOREtitanium alloy electrodes

VIEW MOREtitanium alloy electrodes VIEW MOREtitanium electrodes for salt water electrolysis

VIEW MOREtitanium electrodes for salt water electrolysis VIEW MOREmixed metal oxide coated titanium anodes

VIEW MOREmixed metal oxide coated titanium anodes_1731642168251.webp) VIEW MOREtitanium electrolyzer for electro-chlorination

VIEW MOREtitanium electrolyzer for electro-chlorination