mixed metal oxide coated titanium anodes

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

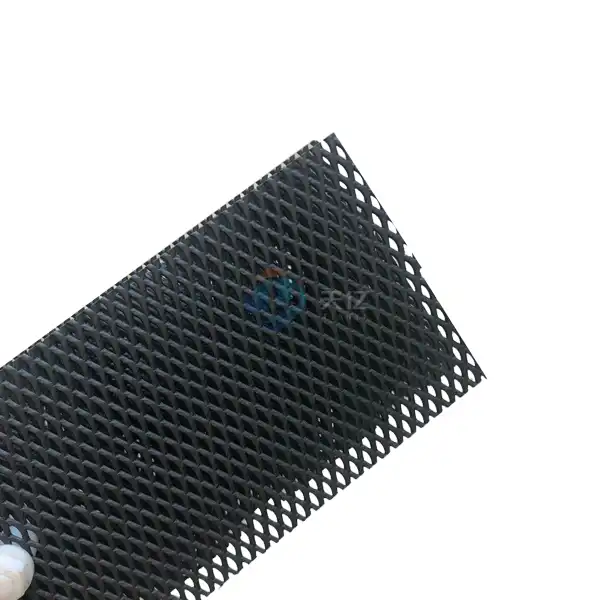

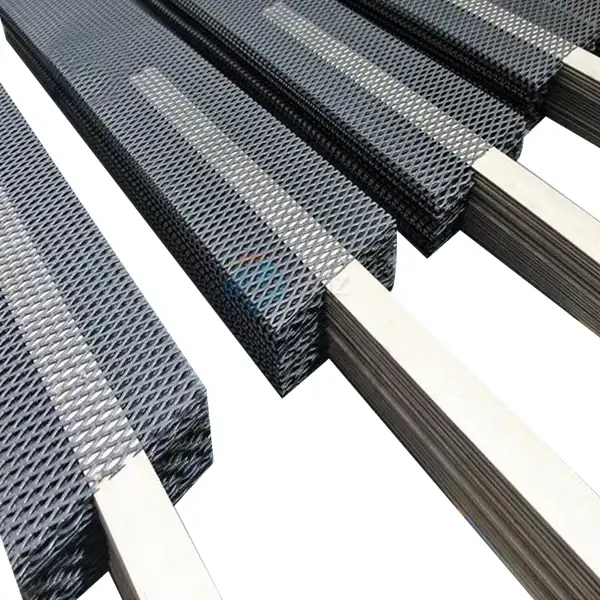

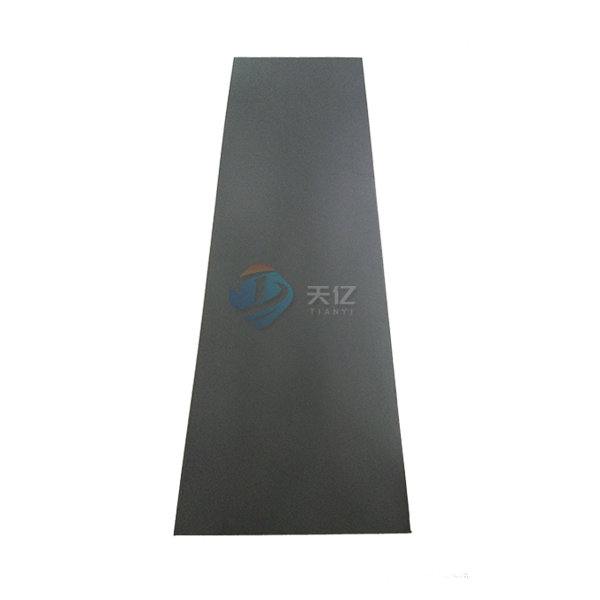

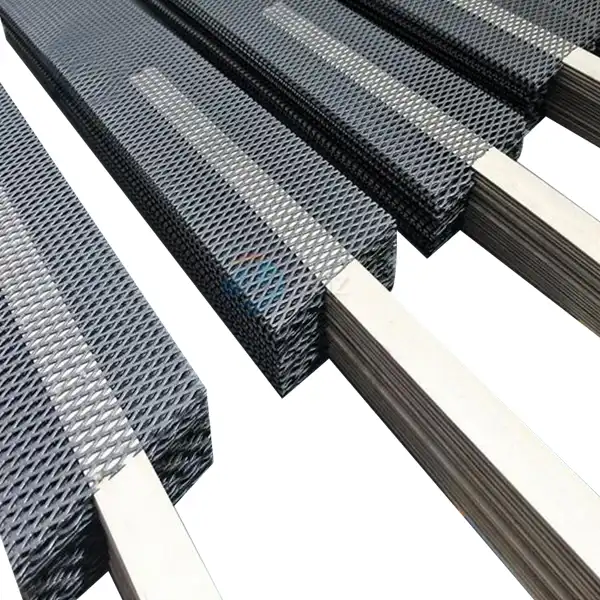

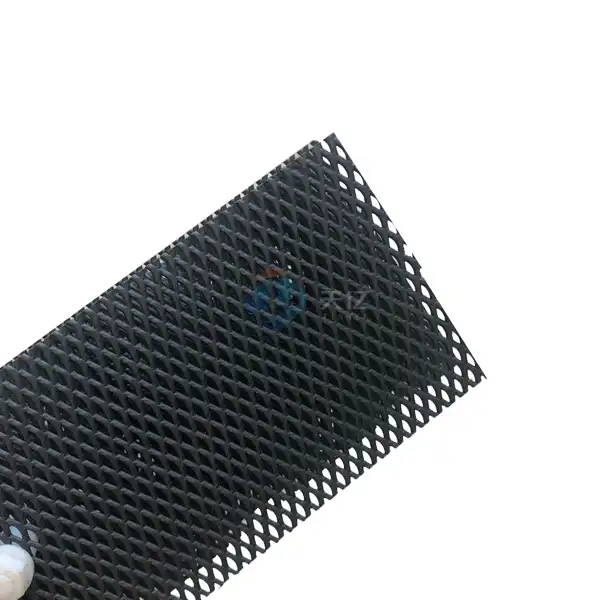

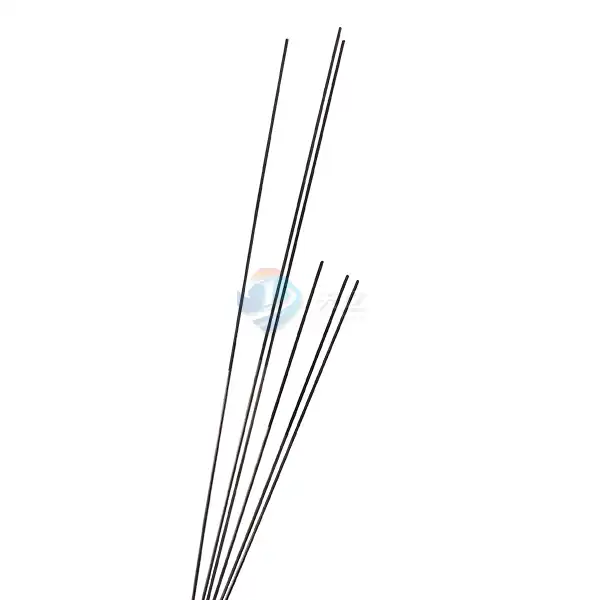

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd.! We take pride in offering high-performance mixed metal oxide (MMO) coated titanium anodes, which are essential for various electrochemical applications. Our mixed metal oxide coated titanium anodes anodes are designed to provide exceptional durability and efficiency, making them ideal for industries such as water treatment, electroplating, and metal processing. Whether you're looking for ruthenium-iridium or iridium-tantalum coatings, we have the right solution for your needs.

Product Specifications

Material | Gr1 Titanium as substrate, MMO as coating |

Coating Types | RuO2 +IRO2 +X |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | <24V |

Current Density | <5,000A/㎡ |

Work time | 80-120 H |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 8~15μm |

Product Composition and Design

Our mixed metal oxide coated titanium anodes are manufactured using high-quality titanium substrates coated with advanced metal oxides. The unique combination of ruthenium, iridium, and tantalum ensures that our anodes exhibit excellent electrochemical stability and corrosion resistance. The design allows for effective current distribution, enhancing overall performance in various electrochemical processes.

Product Advantages

- High Durability: Our MMO anodes are engineered for long-lasting performance, reducing the need for frequent replacements.

- Corrosion Resistance: The high-quality coatings provide superior resistance to corrosion, even in harsh environments.

- Efficient Performance: These anodes exhibit lower overpotential, leading to energy savings during operation.

- Customization: We offer customizable sizes and coatings to meet specific application requirements.

Technical Features

- Superior Electrochemical Properties: Our anodes maintain stable performance across various chemical environments.

- Temperature Tolerance: Designed to operate effectively in high-temperature settings.

- High Current Efficiency: Optimized for maximum current efficiency, contributing to enhanced productivity.

Product Applications

Mixed metal oxide coated titanium anodes are widely used in:

1. Fruit and vegetable disinfection machine

2. Sodium hypochlorite production

3. Chlor-alkali industry

4. Swimming pool water disinfection

5. Wastewater treatment

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

At Shaanxi Tianyi, we utilize a state-of-the-art production process that involves:

Material Selection

High-grade titanium substrates are chosen for their superior strength and corrosion resistance, ensuring optimal performance in various electrochemical applications.

Surface Preparation

The titanium surfaces undergo extensive cleaning, including chemical and mechanical treatments such as sandblasting. This process enhances the surface roughness, facilitating better adhesion of the mixed metal oxide coating.

Coating Formulation

A mixture of metal oxides, typically including iridium, tantalum, and ruthenium, is prepared in a controlled environment. This formulation is crucial to achieving the desired electrochemical properties and stability.

Coating Application

The mixed metal oxide solution is applied to the prepared titanium substrate using techniques like thermal spray or chemical vapor deposition (CVD). Precise control over the application parameters ensures uniform coating thickness.

Heat Treatment

Coated anodes are subjected to a heat treatment process that helps to strengthen the bond between the titanium and the oxide layer. This step also promotes the crystallization of the mixed metal oxides for enhanced conductivity.

Quality Assurance Testing

Each anode undergoes rigorous quality assurance testing, including checking for coating thickness, uniformity, and electrochemical performance. Tests ensure that the anodes meet specified standards for durability and effectiveness.

Final Inspection and Packaging

Finished anodes are inspected for defects and packaged carefully in protective materials to prevent damage during shipping. Each package includes product information, handling guidelines, and safety instructions for end users.

Quality Inspection

Quality is at the forefront of our production. Each anode undergoes:

Visual Inspections:Visual inspections involve examining the coating’s surface for defects such as bubbles, peeling, and scratches. Conducted under good lighting, this method helps identify obvious issues and provides a basis for further testing.

Performance Testing:Performance testing checks if coatings meet specified durability standards through standardized experiments. It assesses factors like wear resistance and corrosion resistance, ensuring the coating can withstand real-world conditions.

Material Testing:Material testing analyzes the raw materials used in coatings to confirm they meet industry standards. This includes assessing composition, density, and viscosity, helping to ensure high-quality and compliant materials are used.

Packaging Method

Our packaging methods are designed to protect your products during transit:

- Custom Packaging: Tailored to fit the specific anodes.

- Safety Features: Using shock-absorbent materials to prevent damage.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We provide comprehensive OEM services, allowing you to customize products according to your specifications. Whether it's a unique coating or a specific dimension, our team is here to support your needs.

FAQ

Q: What is the typical lifespan of MMO coated titanium anodes?

A: The lifespan can range from 5 to 10 years, depending on the application and operating conditions.

Q: Can I get customized sizes?

A: Yes, we offer customized dimensions to suit your specific requirements.

Q: What industries use these anodes?

A: Our anodes are used in various industries, including water treatment, electroplating, and cathodic protection.

Contact Us

For more information about our mixed metal oxide coated titanium anodes or to discuss your specific needs, feel free to reach out to us at [info@di-nol.com]. We look forward to partnering with you for all your electrochemical material needs!

YOU MAY LIKE

VIEW MORERuthenium-iridium coated titanium anode

VIEW MORERuthenium-iridium coated titanium anode VIEW MOREMMO-Ti Wire Anode

VIEW MOREMMO-Ti Wire Anode VIEW MOREElectric water heater anode rod

VIEW MOREElectric water heater anode rod VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MORERuthenium-iridium oxide coated titanium anode

VIEW MORERuthenium-iridium oxide coated titanium anode VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode_1731642449066.webp) VIEW MOREAcidic oxidation potential water generator

VIEW MOREAcidic oxidation potential water generator VIEW MOREiridium oxide coated titanium anodes

VIEW MOREiridium oxide coated titanium anodes