Ruthenium-iridium oxide coated titanium anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

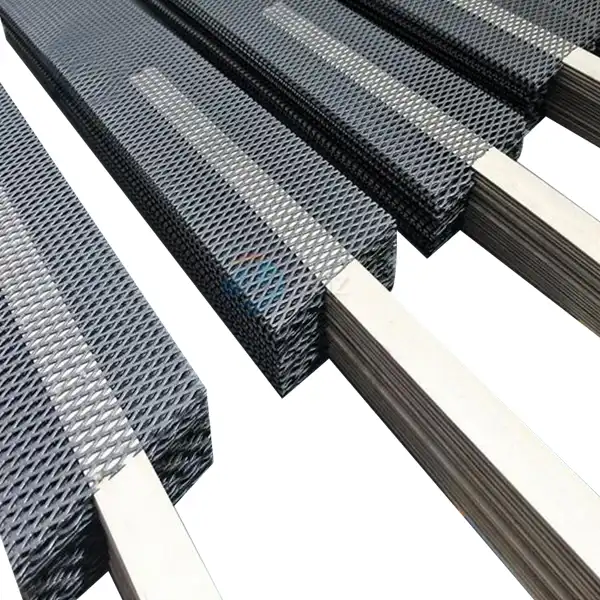

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Ruthenium-Iridium Oxide Coated Titanium Anode Introduction

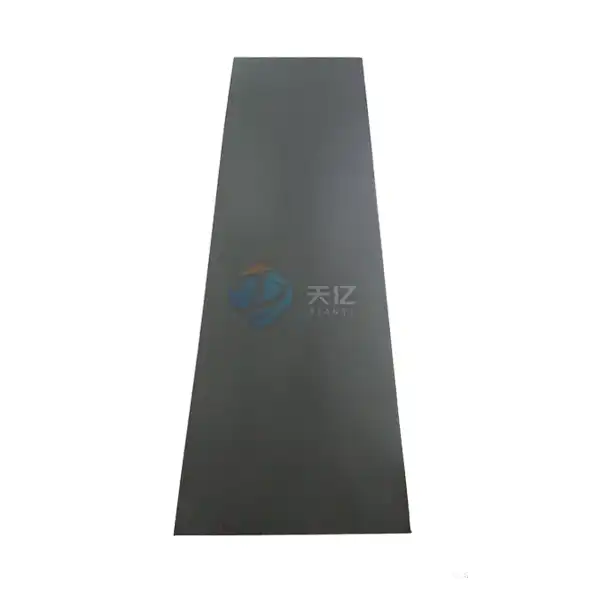

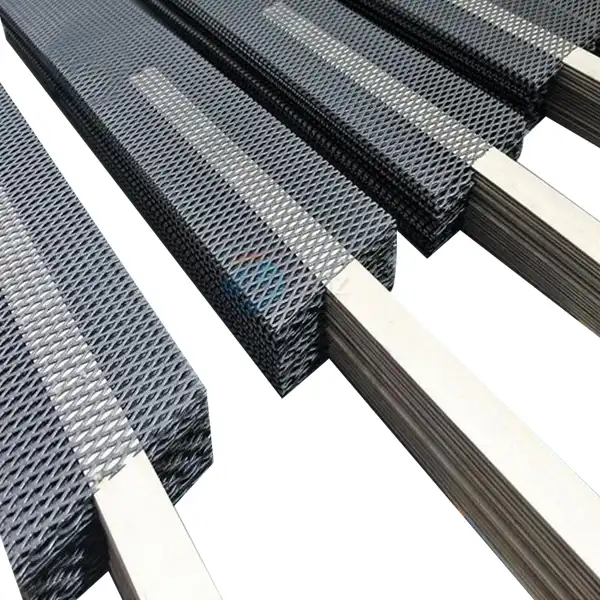

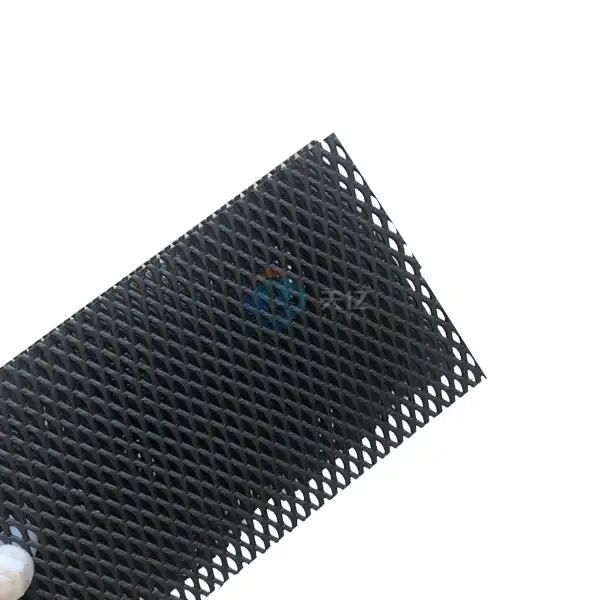

Ruthenium-iridium oxide coated titanium anode is a type of mixed-metal oxide (MMO) anode commonly used in applications such as electroplating, water treatment, and various electronic processes. These anodes are typically available in a wide range of quantities and can be manufactured in different forms, including sheets, mesh, perforated plates, rods, or wires.

Tianyi offers these materials in high purity and ultra-high purity levels (up to 99.99999%) and adheres to applicable ASTM testing standards. Various grades are available, including military specification (Mil Spec), ACS, Reagent and Technical Grade, Food, Agricultural, and Pharmaceutical Grade, Optical Grade, as well as USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) standards.

Product Specifications

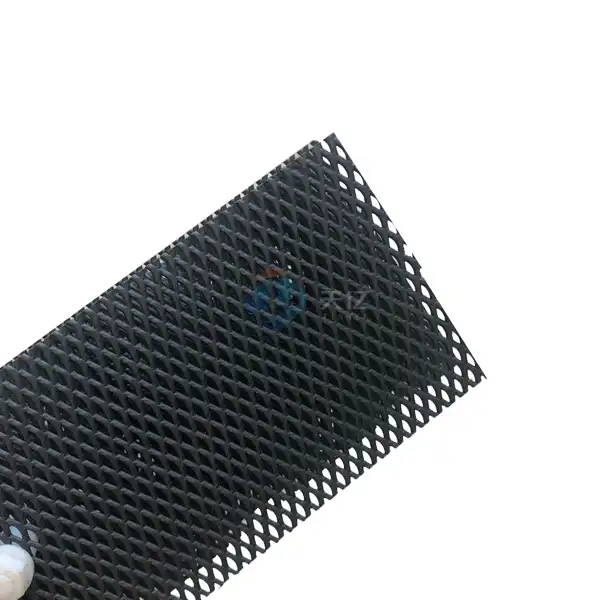

Material | Gr1 Titanium as substrate, MMO as coating |

Coating Types | RuO2 +IRO2 +X |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | <24V |

Current Density | <5,000A/㎡ |

Work time | 80-120 H |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 8~15μm |

Product Composition and Design

Our ruthenium-iridium oxide coated titanium anodes are crafted from premium titanium alloys, ensuring superior mechanical properties and resistance to corrosion. The specialized coating is meticulously applied to enhance the anode's performance, making it suitable for a wide range of electrochemical processes.

Product Advantages

- Exceptional Durability: Designed to withstand harsh environments, these anodes exhibit long service life, ensuring reliable performance even in extreme conditions such as high humidity, corrosive atmospheres, and abrasive settings, which significantly reduces the need for frequent replacements and maintenance.

- High Efficiency: Optimized for excellent electrical conductivity and minimal energy consumption, these anodes facilitate superior performance in various applications, leading to faster processing times and reduced operational costs, while ensuring that energy resources are used effectively and sustainably.

- Versatile Applications: Suitable for a variety of industries, including electroplating, water treatment, and cathodic protection, these anodes can be tailored to meet specific needs in different sectors, enhancing their functionality and performance across diverse processes and environments.

Technical Features

- High Chemical Stability: The ruthenium-iridium coating offers unparalleled chemical stability, reducing the likelihood of coating degradation.

- Enhanced Current Efficiency: Maximizes the efficiency of electrochemical reactions, leading to faster processing times.

Product Application

Our ruthenium-iridium oxide coated titanium anodes are extensively used in:

Chlor-Alkali Industry: These anodes are widely used in the chlor-alkali industry as Dimensionally Stable Anodes (DSA) for the production of chlorine, caustic soda, and other chlorinated products .

Electrochemical Water Treatment: They are employed in water treatment processes for the electrochemical degradation of organic pollutants and the removal of heavy metals from wastewater .

Electrolysis of Water: Ruthenium-iridium oxide coated titanium anodes are used in the electrolysis of water for hydrogen production, owing to their high electrocatalytic activity for the oxygen evolution reaction .

Supercapacitors: These anodes have potential applications in supercapacitors due to their good electrochemical performance and stability .

Cathodic Protection: They are used in cathodic protection systems to prevent corrosion of metals in aggressive environments .

Organic Electrooxidation: The anodes are also used in the electrochemical oxidation of organic compounds, making them suitable for applications in the electrochemical synthesis industry .

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

The manufacturing of our titanium anodes involves rigorous processes:

- Raw Material Sourcing: Only high-grade titanium alloys are selected.

- Coating Application: Coatings are applied through advanced electrochemical methods.

- Final Testing: Each anode undergoes stringent quality control tests to ensure compliance with industry standards.

Quality Inspection

We implement comprehensive quality assurance protocols, including:

- Raw Material Checks: Ensuring only the best materials are utilized.

- In-Process Monitoring: Continuous assessment during production.

- Final Product Testing: Rigorous testing to guarantee performance and reliability.

Packaging Method

Our packaging solutions prioritize safety and efficiency. Each anode is carefully packaged to prevent damage during transit, using:

Foam-based inserts: These supplements are unequivocally formed to fit various shapes and sizes to keep the item set up. They give the best padding and security during capacity and transportation, bringing down the probability of harm and further developing the general client experience.

Eco-friendly materials: These materials are obtained reasonably, zeroly affect the climate, and are totally biodegradable or recyclable.They likewise keep up with elite execution and quality guidelines while likewise adding to a greener planet and lining up with eco-cognizant customer values.

OEM Service

We offer tailored OEM services, allowing you to customize the anodes to meet your specific requirements. Whether it’s adjusting dimensions or coating specifications, our team is ready to assist.

FAQ

Q1: What is the lifespan of ruthenium-iridium oxide coated titanium anodes?

A: Our anodes are designed for long-lasting performance, often exceeding several years depending on the application and operating conditions.

Q2: Can these anodes be used in both acidic and alkaline environments?

A: Yes, they are specifically engineered to perform effectively in a wide range of pH conditions.

Q3: What are the typical applications of these anodes?

A: They are widely used in electroplating, water treatment, and hydrogen production, among others.

Contact Us

For more information on our Ruthenium-Iridium Oxide Coated Titanium Anodes or to place an order, please contact us at [info@di-nol.com]. Our team is here to provide you with the best solutions tailored to your needs.

YOU MAY LIKE

VIEW MORERuthenium-iridium coated titanium anode

VIEW MORERuthenium-iridium coated titanium anode VIEW MOREMMO Ribbon Anode

VIEW MOREMMO Ribbon Anode VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode VIEW MOREmixed metal oxide coated titanium anodes

VIEW MOREmixed metal oxide coated titanium anodes VIEW MOREanodic oxide coating titanium

VIEW MOREanodic oxide coating titanium VIEW MOREiridium oxide coated titanium anodes

VIEW MOREiridium oxide coated titanium anodes