Ruthenium-iridium coated titanium anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

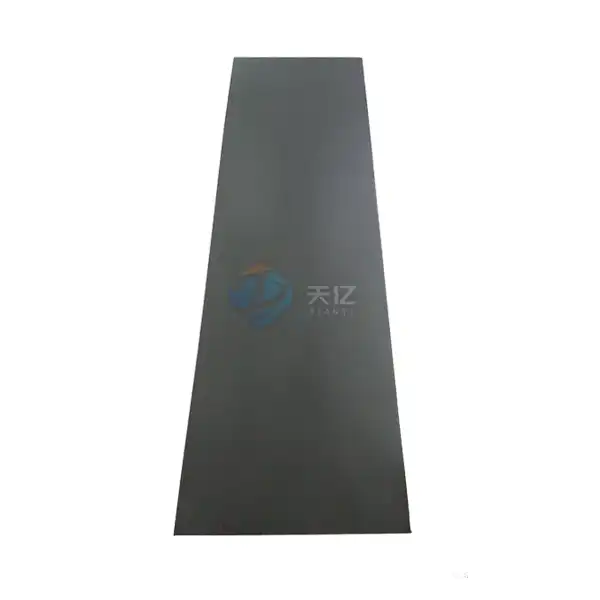

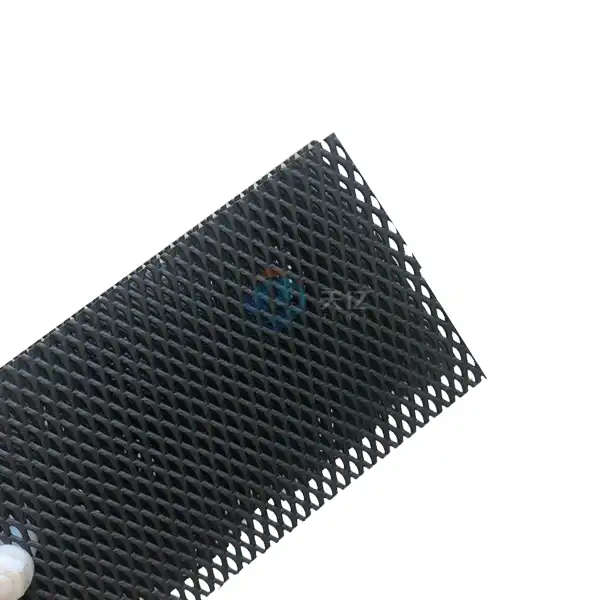

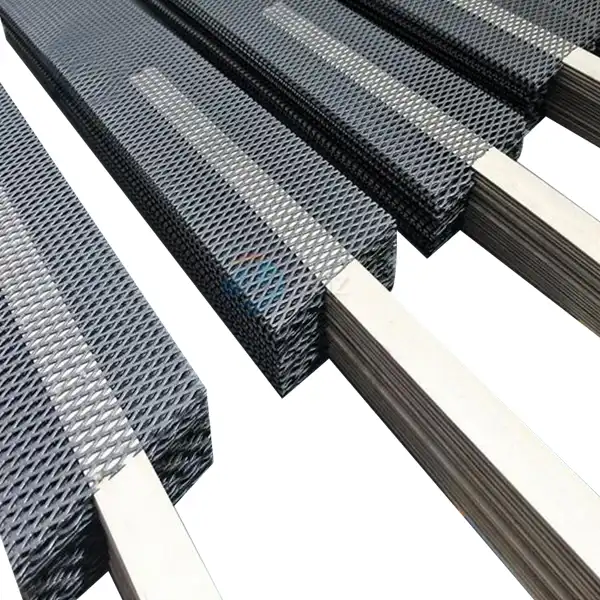

Customizable geometry of oxide-coated titanium anodes

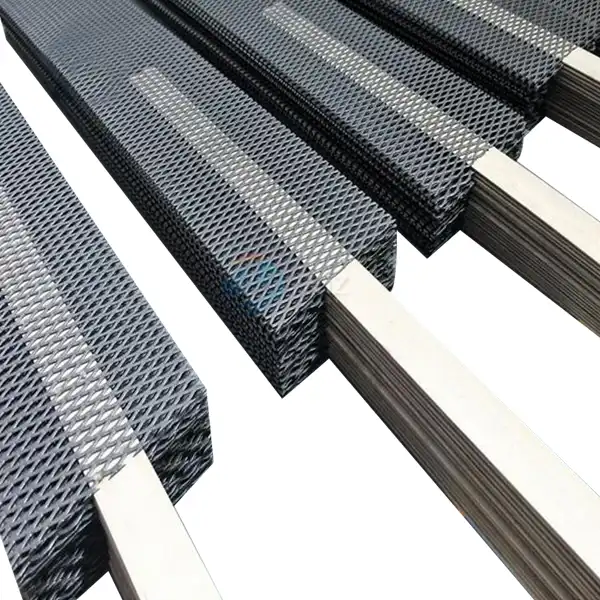

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Ruthenium-iridium Coated Titanium Anode Introduction

A ruthenium-iridium coated titanium anode is a type of mixed-metal oxide (MMO) anode that is used in various applications, including:

Electroplating

Water treatment

Water disinfection

Chlor-alkali production

Primary metal refining

Electrochemical wastewater treatment

Landfill leachate treatment

Ruthenium-iridium coated titanium anode is made of a titanium substrate that is coated with ruthenium and iridium oxide. They are known for their:

Durability: The combination of ruthenium, iridium, and titanium makes the electrode more resistant to wear and breakage.

Corrosion resistance: The iridium in the coating helps to protect the electrode and surrounding equipment from corrosion.

Temperature resistance: Ruthenium-iridium coated electrodes are resistant to high temperatures.

Mechanical strength: Ruthenium-iridium coated electrodes are mechanically strong.

Product Specifications

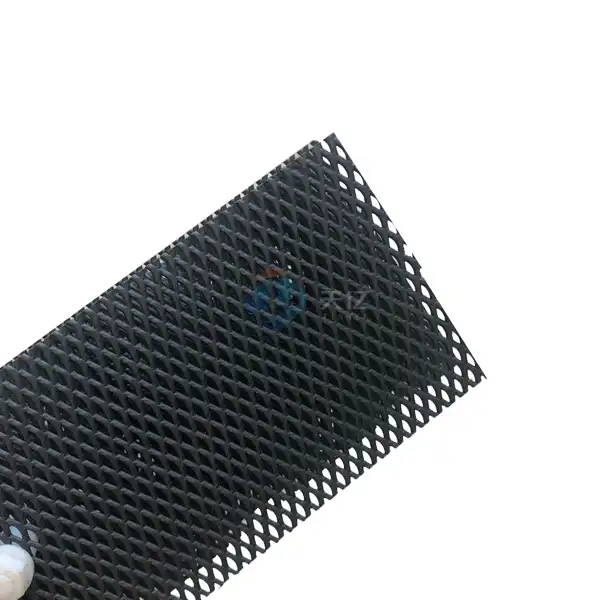

Material | Gr1 Titanium as substrate, MMO as coating |

Coating Types | RuO2 +IRO2 +X |

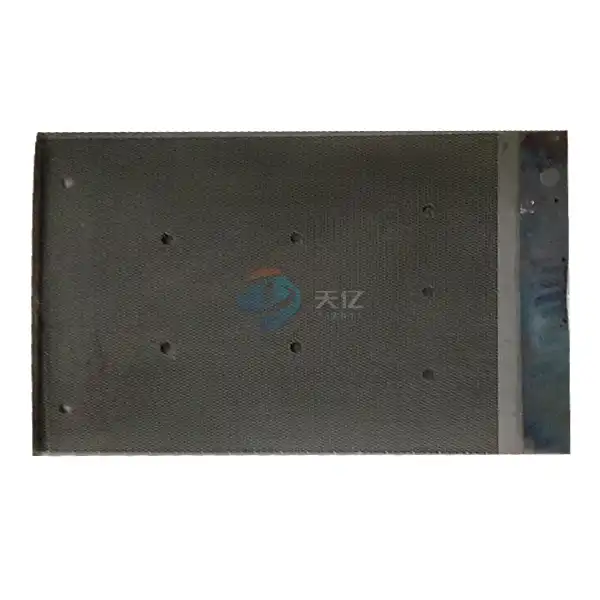

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | <24V |

Current Density | <5,000A/㎡ |

Work time | 80-120 H |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 8~15μm |

Product Composition and Design

Our Ruthenium-Iridium Coated Titanium Anode features a precise coating of ruthenium and iridium, providing excellent corrosion resistance and conductivity. The titanium substrate ensures lightweight durability, making it ideal for various applications. This unique composition allows for superior performance in harsh environments.

Product Advantages

- Corrosion Resistance: The Ruthenium-Iridium Coated Titanium Anode coating offers outstanding protection against corrosive environments, ensuring longevity and reliability.

- High Conductivity: Enhanced electrical conductivity improves efficiency in electrochemical processes.

- Versatile Applications: Suitable for a wide range of industries, from water treatment to electroplating.

- Customizable Solutions: Tailored to meet specific operational needs, ensuring optimal performance.

Technical Features

- Low Overpotential:Significantly reduces energy consumption during operation, thereby enhancing overall efficiency and contributing to lower operational costs.

- Stability: Effectively maintains performance over extended periods, even under demanding conditions, ensuring reliability and longevity of the system.

- Eco-Friendly: Actively supports sustainable practices by reducing waste and improving process efficiency, which in turn promotes a healthier environment and responsible resource usage.

Product Applications

1. Fruit and vegetable disinfection machine

2. Sodium hypochlorite production

3. Chlor-alkali industry

4. Swimming pool water disinfection

5. Wastewater treatment

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Quality Inspection

Our rigorous quality control process includes:

Material Testing:Material testing ensures that all raw materials used in our coatings meet our high standards for quality and performance. This includes analyzing their chemical composition and physical properties to guarantee reliability and compliance with industry regulations.

Coating Evaluation:Coating evaluation involves inspecting the thickness and adhesion of the coating to the substrate. This process ensures proper application and adherence, which are crucial for the coating’s durability and protective capabilities.

Performance Testing:Performance testing includes electrochemical tests to verify the efficiency and durability of our coatings. These tests simulate real-world conditions, assessing resistance to corrosion and wear to ensure the coating meets our stringent performance standards.

Packaging Method

We prioritize safety and efficiency in our packaging. Each anode is securely packaged to prevent damage during transportation, using materials that protect against moisture and corrosion.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services. Our team works closely with clients to develop custom solutions that fit specific requirements, ensuring high performance and satisfaction.

FAQ

1. What is the expected lifespan of the Ruthenium-Iridium Coated Titanium Anode?

- The expected service life is up to 10 years, depending on the operating conditions.

2. Can these anodes be customized?

- Yes, we offer fully customizable solutions tailored to your specific needs.

3. What industries can benefit from this product?

- Industries such as water treatment, electroplating, and cathodic protection can benefit significantly.

Contact Us

For more information or to discuss your specific needs, please reach out to us at [info@di-nol.com]. Our dedicated team is here to assist you!

YOU MAY LIKE

VIEW MORELead dioxide electrode

VIEW MORELead dioxide electrode VIEW MOREWater heater power anode rod

VIEW MOREWater heater power anode rod VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MORERuthenium-iridium oxide coated titanium anode

VIEW MORERuthenium-iridium oxide coated titanium anode VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode VIEW MOREmixed metal oxide coated titanium anodes

VIEW MOREmixed metal oxide coated titanium anodes VIEW MOREiridium oxide coated titanium anodes

VIEW MOREiridium oxide coated titanium anodes VIEW MORETitanium Anode For Metal Electroplating

VIEW MORETitanium Anode For Metal Electroplating