Ruthenium-iridium mixed oxide coated titanium anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

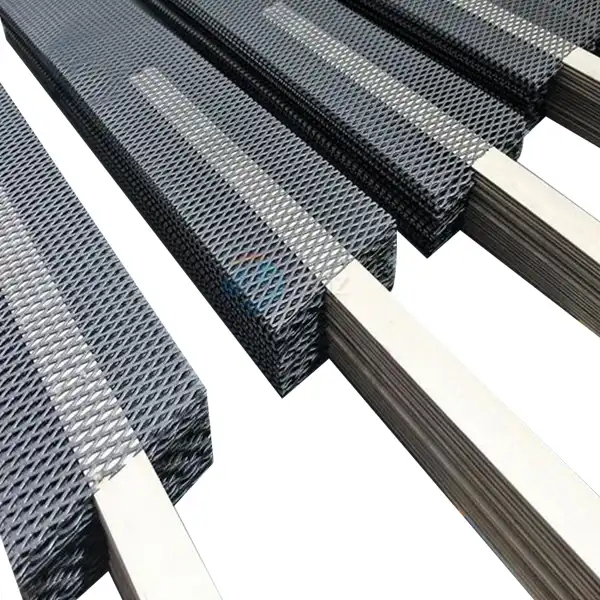

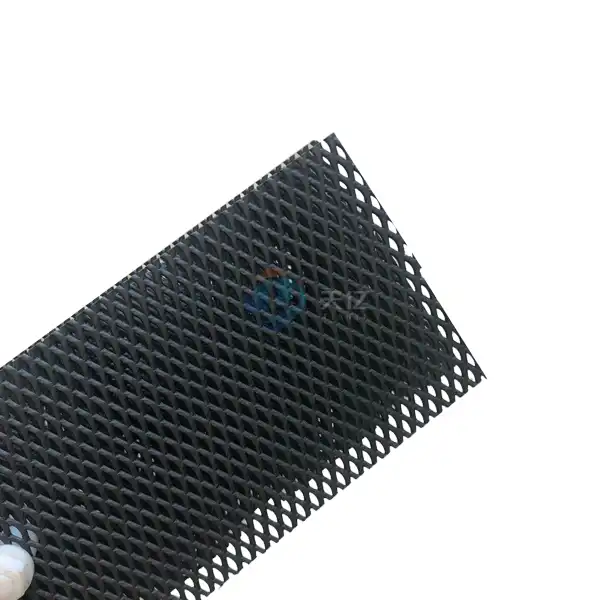

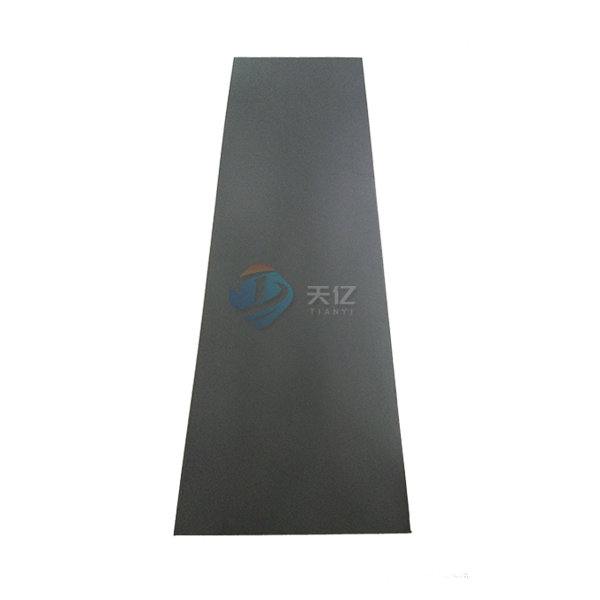

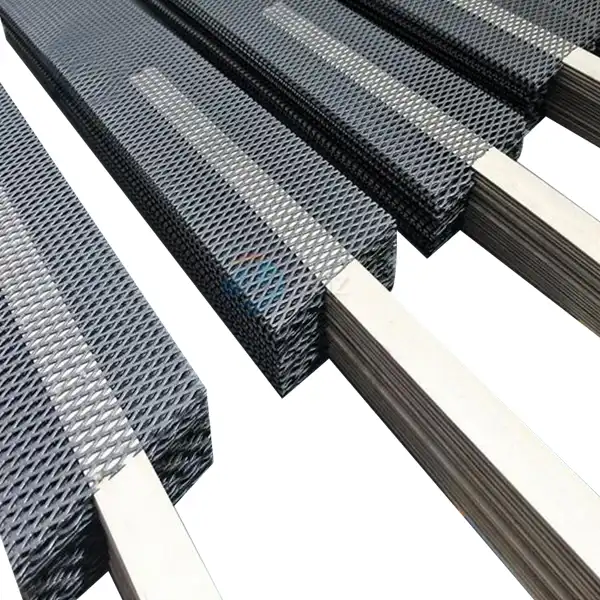

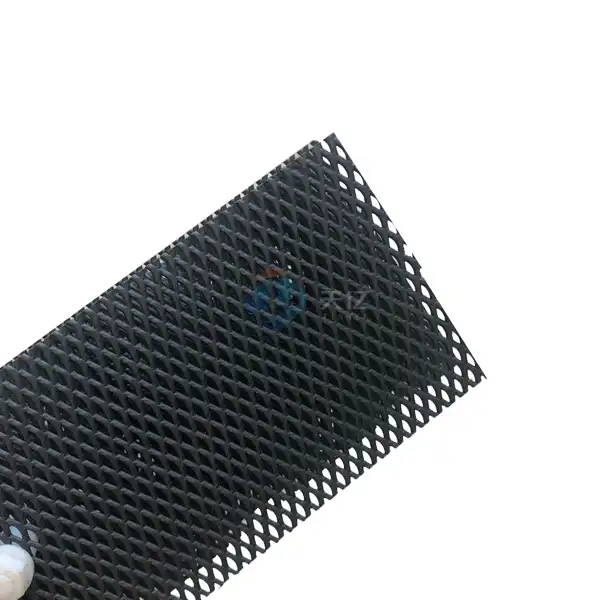

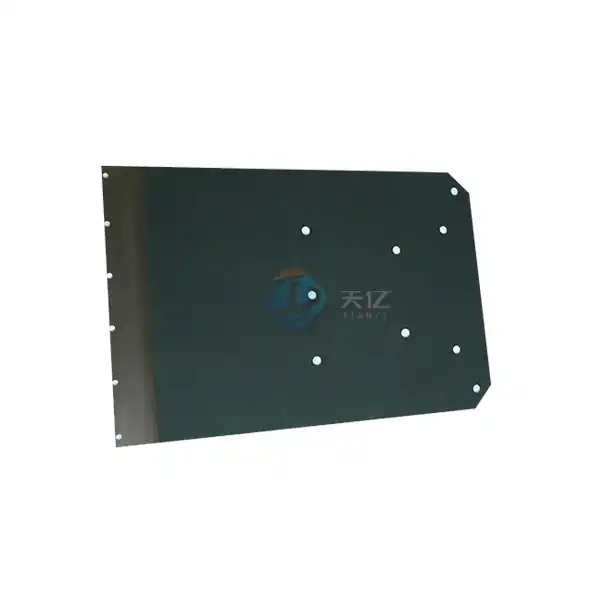

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

The Ruthenium-Iridium Mixed Oxide Coated Titanium Anode is a state-of-the-art electrochemical electrode material designed for high-performance applications in various industries. Our anodes are crafted from high-quality titanium substrates coated with a mixture of ruthenium and iridium, providing exceptional durability and corrosion resistance. This innovative design makes them suitable for a wide range of applications, including electroplating, cathodic protection, and water treatment.

Product Specifications

Material | Gr1 Titanium as substrate, MMO as coating |

Coating Types | RuO2 +IRO2 +X |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | <24V |

Current Density | <5,000A/㎡ |

Work time | 80-120 H |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 8~15μm |

Product Composition and Design

The coating consists of ruthenium and iridium, which are deposited on a Ruthenium-Iridium Mixed Oxide Coated Titanium Anodeusing advanced electrochemical techniques. This combination enhances the anode's conductivity and electrochemical stability, ensuring long-lasting performance. The unique design minimizes wear and extends operational lifetimes, making them ideal for demanding industrial environments.

Product Advantages

- High Durability: The ruthenium-iridium coating provides excellent resistance to corrosion and abrasion.

- Long Service Life: Extended operational lifespan reduces the need for frequent replacements, resulting in cost savings.

- Wide Applicability: Suitable for various industries, including electroplating, water treatment, and cathodic protection.

- Customization: Available in different sizes and specifications to meet specific client requirements.

Technical Features

Electrochemical Stability: The system is designed to maintain stable performance in harsh environments, ensuring reliable operation under extreme temperatures and high humidity, which extends its lifespan.

High Current Efficiency: Utilizing advanced materials and design, the system achieves high current efficiency in electrochemical processes, maximizing energy conversion and improving productivity.

Eco-Friendly: The product is designed to minimize environmental impact during operation by using sustainable materials and energy-efficient technologies, aligning with environmental standards and contributing to a healthier planet.

Product Application

The Ruthenium-Iridium Mixed Oxide Coated Titanium Anode is widely used in:

1. Fruit and vegetable disinfection machine

2. Sodium hypochlorite production

3. Chlor-alkali industry

4. Swimming pool water disinfection

5. Wastewater treatment

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our Ruthenium-Iridium Mixed Oxide Coated Titanium Anode process follows stringent quality control measures:

Raw Material Selection

High-quality titanium is selected as the substrate due to its excellent mechanical strength and corrosion resistance. The purity of the titanium is crucial for ensuring the longevity and performance of the anode.

Surface Preparation

The titanium substrates undergo a rigorous cleaning process, including acid cleaning and mechanical polishing. This prepares the surface for optimal adhesion of the ruthenium-iridium oxide coating by removing contaminants and enhancing surface roughness.

Preparation of Oxide Mixture

A precise formulation of ruthenium and iridium oxides is created, often in the presence of other additives to improve conductivity and electrochemical performance. The ratios of these oxides are carefully controlled to achieve the desired properties.

Coating Application

The ruthenium-iridium oxide mixture is applied to the titanium substrate using techniques such as thermal decomposition, sol-gel coating, or electrochemical deposition. Each method is selected based on the desired thickness and uniformity of the coating.

Heat Treatment

Coated anodes are subjected to a heat treatment process, where they are heated in a controlled environment. This step facilitates the formation of a stable oxide layer and enhances the bonding strength between the coating and the titanium substrate.

Quality Assurance Testing

Each finished anode undergoes comprehensive testing to evaluate its electrochemical properties, including activity, stability, and longevity. Parameters such as coating thickness and adhesion are also assessed to ensure compliance with industry standards.

Final Packaging

After passing all quality checks, the anodes are carefully packaged in protective materials to prevent damage during shipping. Each package includes product specifications, safety guidelines, and handling instructions for end users.

Quality Inspection

Every batch of our anodes undergoes comprehensive quality checks, including:

- Material Verification: Ensures compliance with specifications.

- Coating Thickness Measurement: Confirming the optimal thickness for performance.

- Performance Testing: Conducted under various conditions to validate durability and efficiency.

Packaging Method

We provide custom packaging solutions designed to ensure the safety of the anodes during transportation. Packaging materials are eco-friendly and designed to prevent damage.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi provides a wide range of comprehensive OEM (Original Equipment Manufacturer) services specifically designed to meet the unique requirements of our diverse clientele. We prioritize collaboration and work closely with our customers to understand their specific needs and challenges. By doing so, we are able to develop tailored solutions that not only enhance product performance but also effectively address particular application demands. Our commitment to customization ensures that each client receives a solution that aligns perfectly with their operational goals and expectations, ultimately driving success in their respective markets.

FAQ

Q: What is the lifespan of a Ruthenium-Iridium Coated Titanium Anode?

A: Typically, they last between 5 to 10 years, depending on the operating conditions.

Q: Can these anodes be customized?

A: Yes, we offer customization in size, specifications, and coating thickness based on client requirements.

Q: What industries benefit from using these anodes?

A: Industries such as electroplating, water treatment, and cathodic protection utilize these anodes extensively.

Contact Us

For more information or to request a quote, please contact us at [info@di-nol.com]. Our dedicated team is here to assist you with your needs and ensure you find the perfect electrochemical solutions for your applications.

YOU MAY LIKE

VIEW MORERuthenium-iridium coated titanium anode

VIEW MORERuthenium-iridium coated titanium anode VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MORERuthenium-iridium oxide coated titanium anode

VIEW MORERuthenium-iridium oxide coated titanium anode VIEW MOREtitanium alloy electrodes

VIEW MOREtitanium alloy electrodes VIEW MOREmixed metal oxide coated titanium anodes

VIEW MOREmixed metal oxide coated titanium anodes VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil

VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil VIEW MOREiridium oxide coated titanium anodes

VIEW MOREiridium oxide coated titanium anodes