Ir-Ta Titanium Anode for Electrolytic Copper Foil

Maximum recovery

High-precision metal extraction

Environmental sustainability

High versatility

- Product Description

Product Introduction

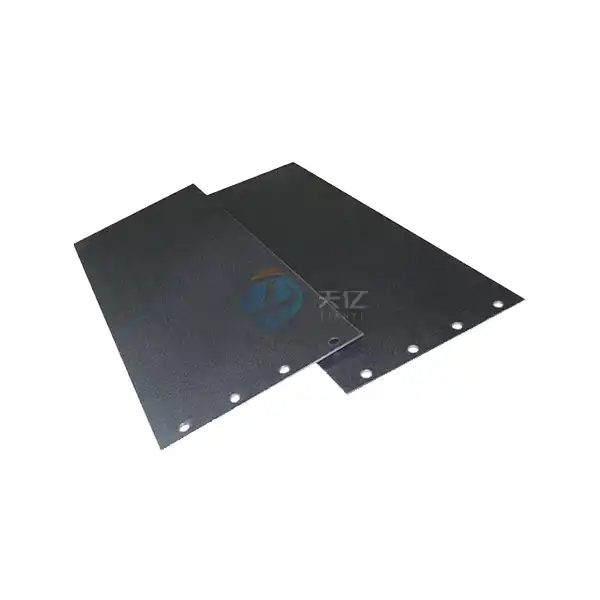

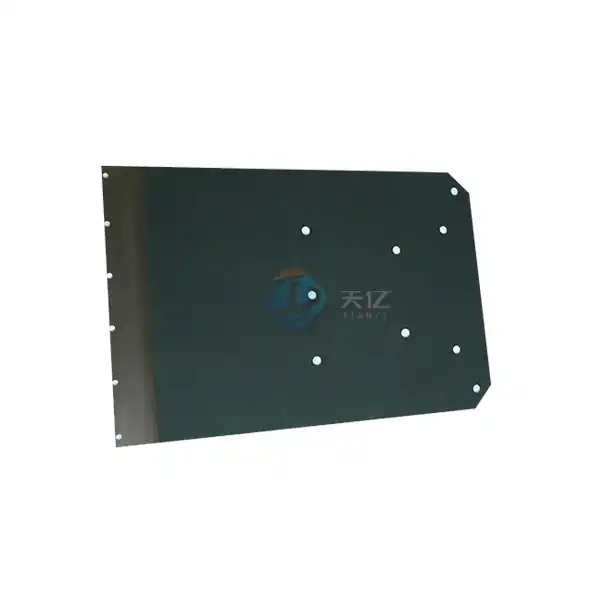

The Ir-Ta Titanium Anode for Electrolytic Copper Foil is engineered to enhance the efficiency of copper foil production, a crucial process in electronics manufacturing. Our high-performance Mixed Metal Oxide (MMO) coated titanium anode combines iridium and tantalum to provide exceptional durability and corrosion resistance, ensuring optimal performance in electrochemical applications. With a focus on innovation and quality, Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. delivers solutions that meet the highest industry standards.

Product Specifications

Substrate: Gr1/Gr2 Pure Titanium ASTM265

Coating: Ir-Ta

Operation Current: 5000-8000A/m2

Electrolyte:Cu2+:50-150g/L,

H2SO4:60-150g/L

Cl-:30-60ppm

Additives: 2-5ppm

Operation temperature:50-80℃

Lifespan: More than 8 month

|  |

|  |

Product Composition and Design

The Ir-Ta Titanium Anode for Electrolytic Copper Foil features a precise composition of iridium and tantalum, optimized for enhanced conductivity and longevity. The MMO coating is applied through a state-of-the-art manufacturing process, ensuring uniform thickness and excellent adherence to the titanium substrate. This design minimizes electrochemical degradation and enhances the overall performance in electrolytic processes.

Product Advantages

- High Corrosion Resistance: The unique combination of iridium and tantalum provides outstanding resistance to corrosion, extending the anode's service life.

- Enhanced Efficiency: Our anodes are designed to optimize electrolysis efficiency, leading to lower energy consumption and improved production rates.

- Customizable Solutions: We offer tailored specifications to meet the unique requirements of each client, ensuring compatibility with various systems.

- Cost-Effective Performance: With their durability and efficiency, our anodes reduce replacement frequency and overall operational costs.

Technical Features

- Electrochemical Stability: The anode maintains stable performance over extended operational periods, ensuring consistent output.

- Thermal Stability: Designed to operate effectively across a wide temperature range, our anodes are reliable under varying conditions.

- Non-Toxic Materials: Our manufacturing process utilizes eco-friendly materials, contributing to sustainable practices in the industry.

Product Application

Widely used in metal deposition such as copper, nickel, cobalt, manganese, chromium, zinc, etc.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process involves:

Material Selection

The production of Iridium-Tantalum (Ir-Ta) titanium anodes begins with high-purity titanium as the substrate material. Titanium is chosen for its excellent strength, corrosion resistance, and stability in electrolytic environments.

Titanium Rod Preparation

The titanium is processed into rods or sheets, depending on the specific design and dimensions required for the Ir-Ta anode. This stage includes cutting, grinding, and machining to ensure precise sizing and surface finish.

Surface Treatment

To enhance the adhesion of the Ir-Ta coating, the titanium surface undergoes a treatment process. This may involve sandblasting or chemical etching to create a roughened surface that promotes better bonding with the coating.

Coating Application

The next step involves applying a coating of iridium and tantalum oxides onto the titanium substrate. This can be done through various methods, including thermal spraying or electrochemical deposition, which allows for uniform coverage and optimal thickness.

Coating Curing

Following the application of the Ir-Ta coating, the anodes are subjected to a curing process, which may include heat treatment. This step enhances the adhesion of the coating to the titanium substrate, ensuring durability and longevity during electrolysis.

Quality Control Testing

Rigorous quality control measures are implemented throughout the production process. Each batch of anodes is tested for key parameters such as coating thickness, adhesion strength, and electrical conductivity to ensure compliance with industry standards.

Final Inspection

A thorough inspection is conducted to identify any defects or inconsistencies in the anodes. Visual checks, dimensional measurements, and performance assessments are performed to ensure the anodes meet quality specifications.

Packaging

Once approved, the Ir-Ta titanium anodes are carefully packaged to protect them from damage during transportation. Packaging materials are selected to provide cushioning and shielding from environmental factors.

Documentation and Certification

Each shipment is accompanied by documentation outlining the specifications, operational guidelines, and safety information. This documentation is essential for end-users to understand proper handling and effective utilization of the anodes.

Shipping Logistics

The finished anodes are shipped to customers through reliable logistics partners. Customers receive tracking information to monitor their orders until they reach their destination.

Post-Delivery Support

After delivery, manufacturers provide ongoing technical support to assist customers with installation and operational queries. This ensures that the Ir-Ta titanium anodes perform optimally in electrolytic copper foil applications.

By following this detailed production process, Ir-Ta titanium anodes are engineered to enhance the efficiency and effectiveness of electrolytic copper foil production, providing long-lasting performance and reliability in industrial applications.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Each batch of Ir-Ta titanium anodes undergoes thorough testing, including:

- Dimensional Accuracy: Ensuring the anodes meet specified measurements.

- Corrosion Testing: Assessing resistance to various electrochemical environments.

- Performance Validation: Conducting tests to confirm efficiency and durability under operational conditions.

Packaging Method

Our Ir-Ta Titanium Anode for Electrolytic Copper Foil are packaged with care to prevent damage during transportation. We use:

- Custom Foam Inserts: To protect the anodes from impact.

- Sealed Packaging: Ensuring they remain free from contaminants.

- Labeling: Clear identification of product specifications for easy handling.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing us to produce customized anodes tailored to your specific requirements. Our experienced team collaborates closely with clients to develop solutions that align with their production needs.

FAQ

Q1: What is the lifespan of the Ir-Ta titanium anode?

A: The lifespan can vary based on operational conditions, but our anodes are designed for long-term use, often exceeding industry standards.

Q2: Can I customize the dimensions of the anode?

A: Yes, we offer customizable solutions to meet your specific requirements.

Q3: How do you ensure quality control?

A: We conduct rigorous quality checks throughout the production process, including material inspections and performance testing.

Contact Us

For more information about Ir-Ta Titanium Anode for Electrolytic Copper Foil or to place an order, please reach out to us at [info@di-nol.com]. Our team is ready to assist you with any inquiries or custom solutions you may need.