iridium oxide coated titanium anodes

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

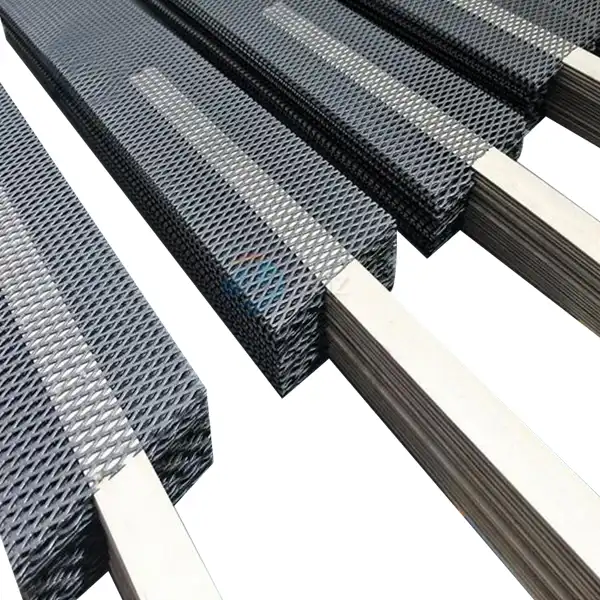

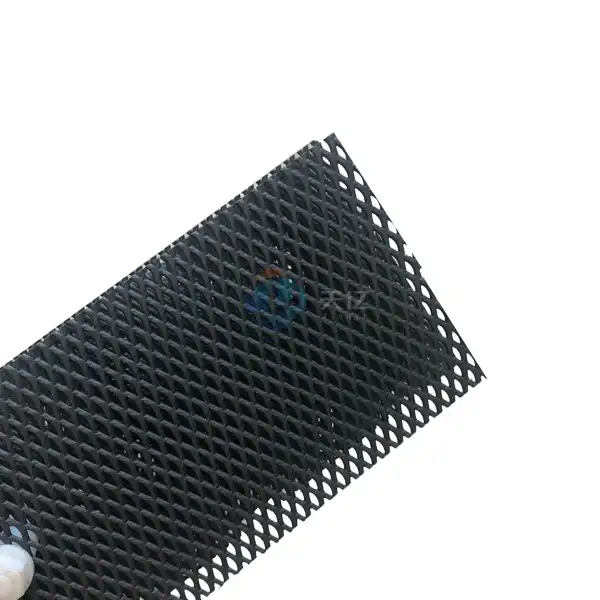

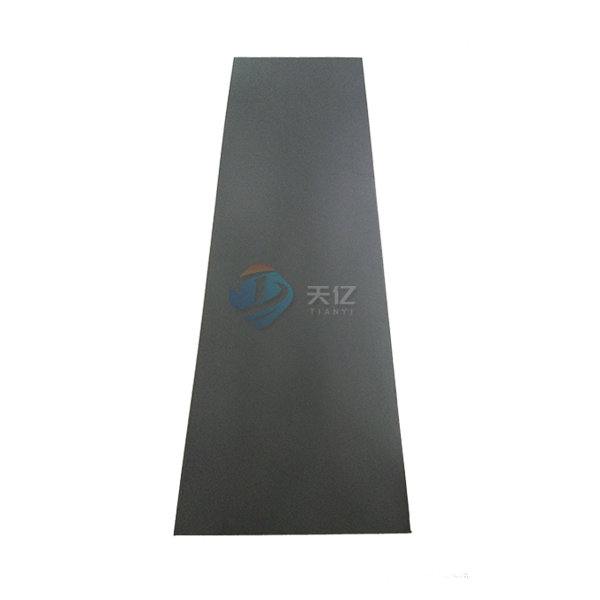

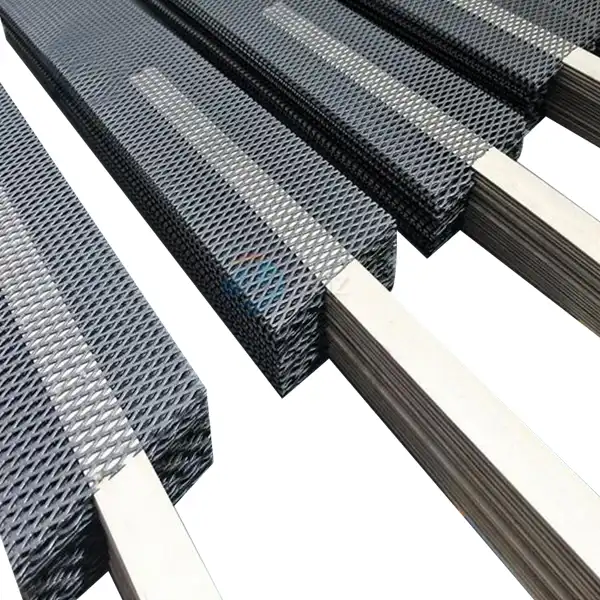

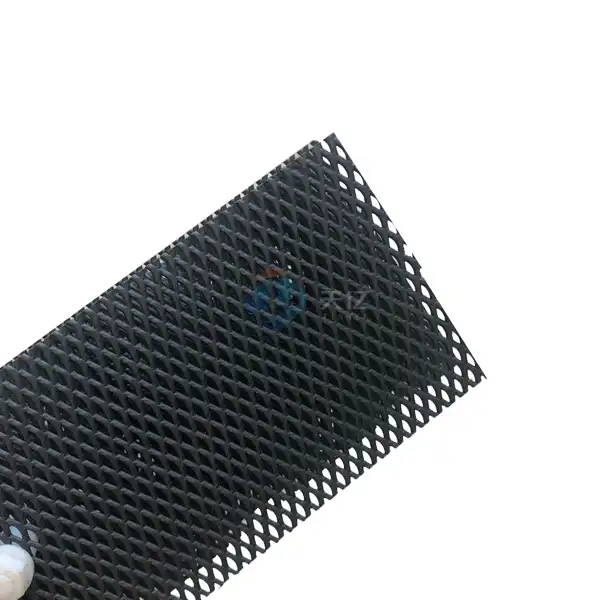

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we pride ourselves on producing top-of-the-line iridium oxide coated titanium anodes. These advanced anodes are engineered for superior performance in various electrochemical applications, ensuring long-lasting durability and efficiency. Whether you are in water treatment, electroplating, or industrial processes, our iridium oxide anodes are designed to meet your specific needs and exceed expectations.

Product Specifications

Material | Gr1 Titanium as substrate, MMO as coating |

Coating Types | RuO2 +IRO2 +X |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | <24V |

Current Density | <5,000A/㎡ |

Work time | 80-120 H |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 8~15μm |

Product Composition and Design

Our iridium oxide coated titanium anodes are composed of high-quality titanium alloys coated with a thin layer of iridium oxide. This unique combination provides exceptional corrosion resistance and enhances the electrochemical activity of the anodes. The design is optimized to facilitate maximum surface area for improved electrolysis efficiency, making them ideal for a wide range of industrial applications.

Product Advantages

- Superior Durability: With a robust construction, our anodes resist wear and corrosion, ensuring a longer lifespan.

- High Efficiency: The iridium oxide coating significantly increases the electrochemical activity, leading to enhanced performance in electrolysis.

- Customizable Options: We offer tailored solutions to meet the specific dimensions and requirements of your projects.

- Environmentally Friendly: Our anodes are designed with sustainability in mind, contributing to greener industrial processes.

Technical Features

- Low Overpotential: This characteristic reduces energy consumption during electrolysis.

- Stable Performance: Our anodes maintain consistent performance over time, even under varying operational conditions.

- Wide Application Range: Suitable for various applications, including electroplating, water treatment, and cathodic protection.

Product Application

Iridium oxide coated titanium anodes are essential in numerous industries, including:

1. Fruit and vegetable disinfection machine

2. Sodium hypochlorite production

3. Chlor-alkali industry

4. Swimming pool water disinfection

5. Wastewater treatment

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process follows stringent quality standards, ensuring each anode meets our high-performance criteria:

Material Selection

High-quality titanium substrates are selected for their excellent corrosion resistance and mechanical properties. This ensures that the anodes will have a long lifespan and optimal performance in various electrochemical applications.

Surface Preparation

The titanium surfaces are meticulously cleaned and prepared through processes such as sandblasting and chemical etching. This treatment increases surface area and promotes better adhesion of the iridium oxide coating.

Coating Application

A thin layer of iridium oxide is applied to the prepared titanium substrate using techniques such as thermal spraying or electrodeposition. This process is precisely controlled to ensure uniform coating thickness and optimal electrochemical activity.

Heat Treatment

The coated anodes undergo a heat treatment process to enhance the adhesion of the iridium oxide layer and improve its stability. This step also contributes to the formation of desired crystalline structures within the coating.

Quality Control and Testing

Each anode is subjected to rigorous quality control checks, including electrical testing to measure conductivity and performance under various conditions. The coating thickness and uniformity are also verified to ensure compliance with specifications.

Final Assembly

The anodes are assembled with necessary fittings and connectors, readying them for integration into electrochemical systems. This step may include adding protective coatings to prevent damage during handling and installation.

Packaging and Shipping

Finished iridium oxide coated titanium anodes are carefully packaged in protective materials to prevent physical damage during transit. Each package is labeled with product specifications, handling instructions, and safety information for the end users.

We employ rigorous quality control measures throughout our production process:

- Material Inspection: All incoming materials undergo detailed testing.

- In-Process Checks: Regular inspections are conducted during manufacturing.

- Final Product Testing: Each anode is tested to ensure it meets our performance standards before shipment.

Packaging Method

Our packaging solutions are designed for safety and efficiency, using:

- Durable Materials: To protect the anodes during transportation.

- Custom Packaging Options: Tailored to meet client specifications, ensuring that products arrive in perfect condition.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, providing customized solutions that perfectly align with your specific requirements. Whether you need tailored designs, unique packaging options, or other specific specifications, our dedicated team is here to support your needs every step of the way, ensuring that we meet and exceed your expectations with high-quality results.

FAQ

Q1: What is the lifespan of iridium oxide coated titanium anodes?

A1: Our anodes typically have a service life of 5-10 years, depending on the application and operating conditions.

Q2: Can you provide custom sizes?

A2: Yes, we offer customizable options for length and width to meet your specific project requirements.

Q3: How do I ensure the right anode for my application?

A3: Our experts are available to assist you in selecting the best anode based on your application needs.

Contact Us

For more information about our iridium oxide coated titanium anodes or to discuss your specific requirements, please contact us at [info@di-nol.com]. Our dedicated team is here to assist you with all your needs!

YOU MAY LIKE

VIEW MORERuthenium-iridium coated titanium anode

VIEW MORERuthenium-iridium coated titanium anode VIEW MOREiccp protected mmo coated titanium anodes

VIEW MOREiccp protected mmo coated titanium anodes VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MORERuthenium-iridium oxide coated titanium anode

VIEW MORERuthenium-iridium oxide coated titanium anode VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode VIEW MORETitanium Anode For Electrodialysis

VIEW MORETitanium Anode For Electrodialysis VIEW MOREmixed metal oxide coated titanium anodes

VIEW MOREmixed metal oxide coated titanium anodes