Lead dioxide electrode

Corrosion resistance

Versatility

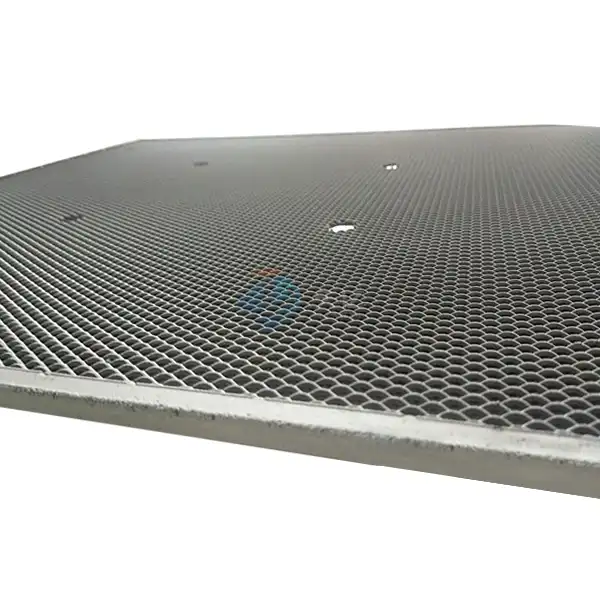

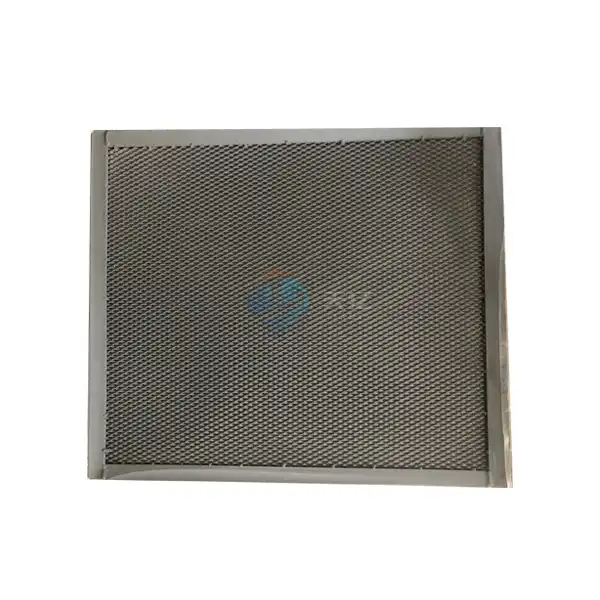

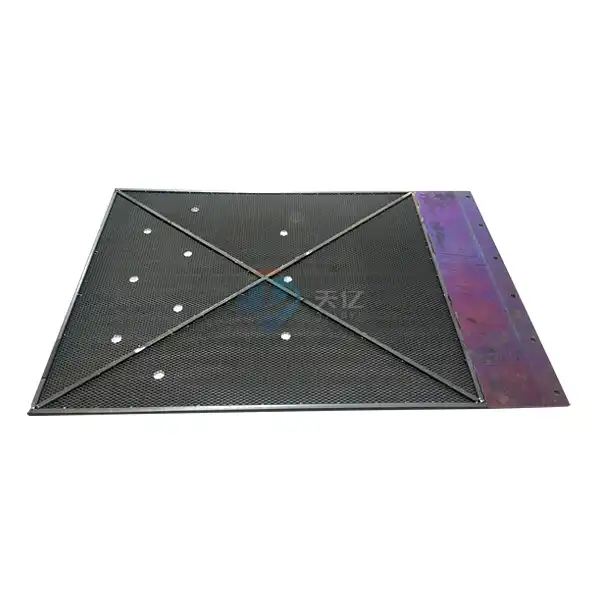

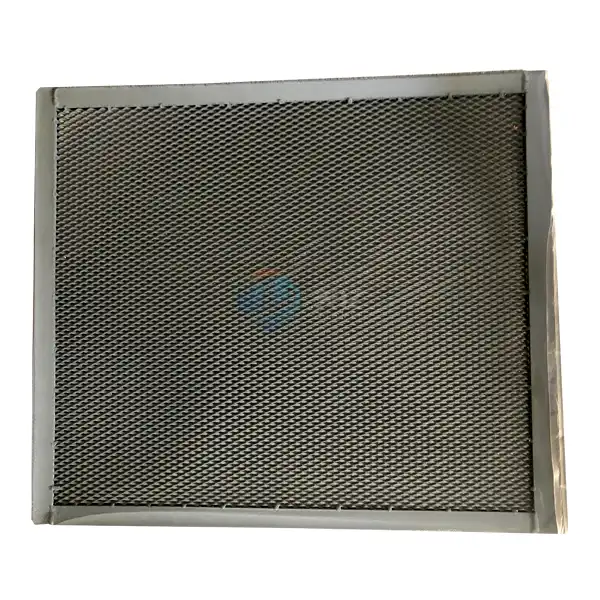

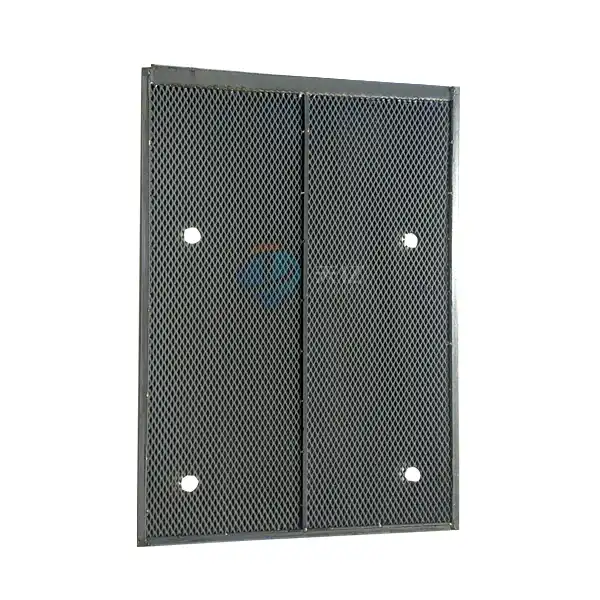

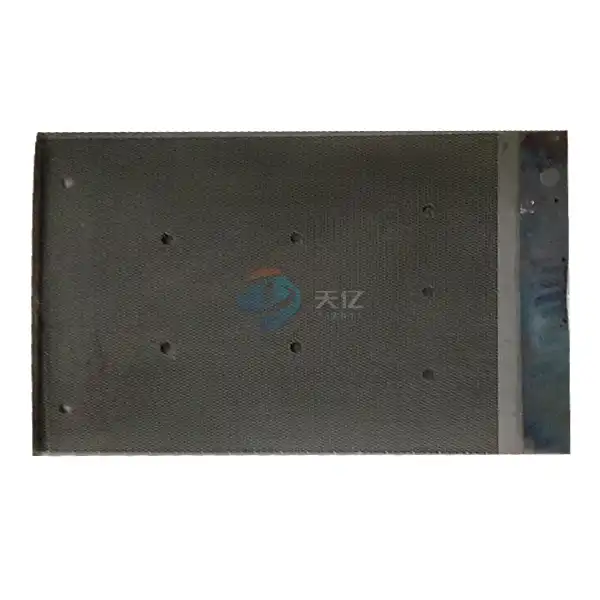

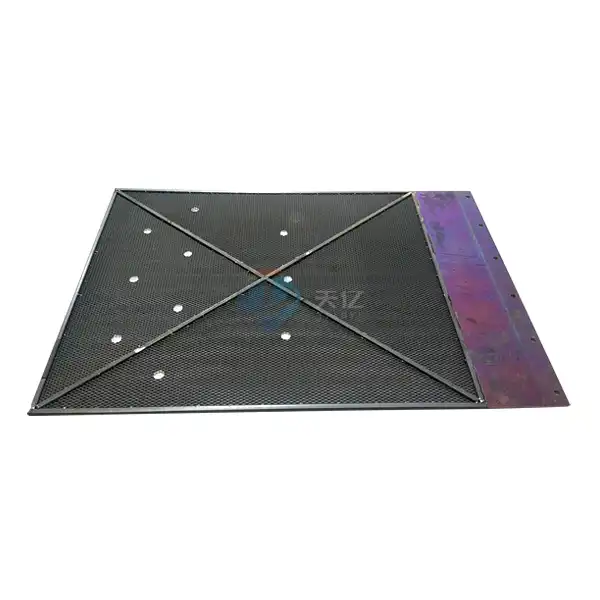

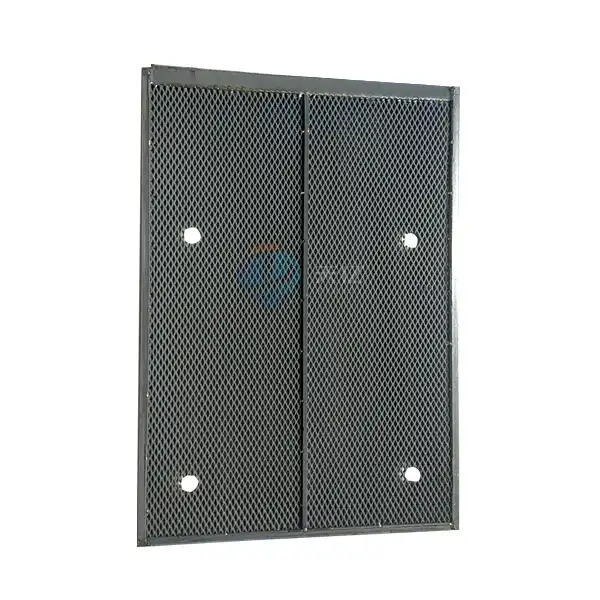

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

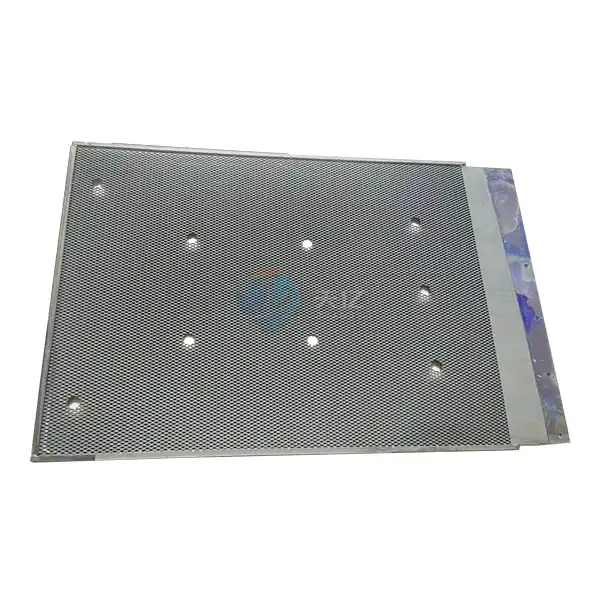

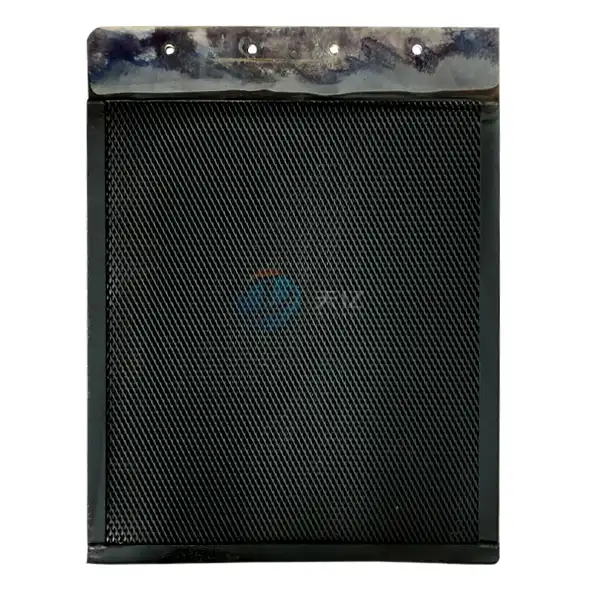

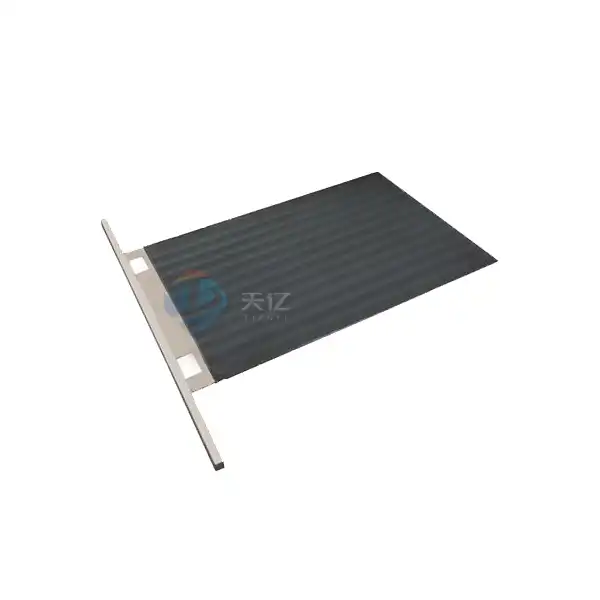

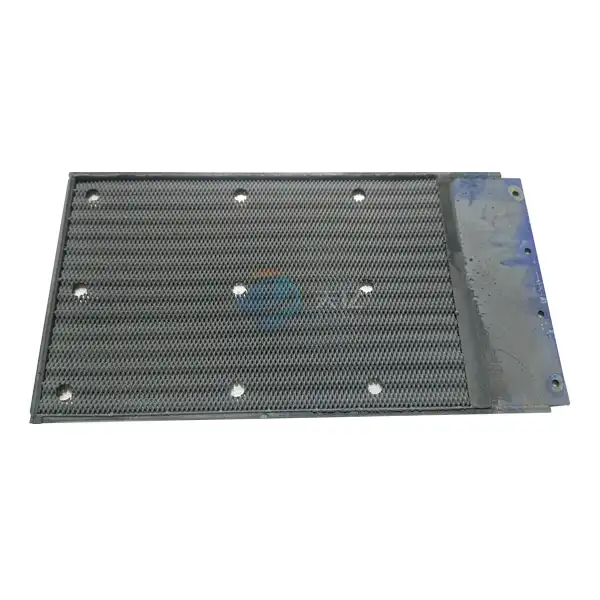

Lead Dioxide Electrode Introduction

TianYI's Lead dioxide electrode are the top choice for industries demanding high-quality, durable, and efficient electrochemical solutions. Our electrodes boast superior conductivity, excellent corrosion resistance, and long service life. Engineered with precision, they ensure optimal performance in various applications, from battery manufacturing to water treatment. Choose TianYI for reliable, cost-effective electrodes that meet your exact specifications.

Product Specifications

Parameter | Specification |

Substrate | Gr1/Gr2 Titanium |

Coating Type | Lead dioxide |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | < 1.13V |

Current Density | < 3000A/M^2 |

Work Time | 80-120 hours |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 1-15μm |

|  |

|  |

Product Composition and Design

Our Lead Dioxide Electrode is constructed from high-quality titanium substrate coated with lead dioxide. This unique composition ensures excellent conductivity and resistance to corrosion, which are essential for long-lasting performance in electrochemical reactions. The design is optimized for efficient current distribution, enhancing the electrode's overall effectiveness in various applications.

Product Advantages

- Durability: Designed to withstand harsh operating conditions, our electrodes have a long service life, minimizing the need for frequent replacements.

- High Efficiency: The unique coating enhances current efficiency, resulting in lower operational costs and increased productivity.

- Versatile Applications: Suitable for a wide range of industrial applications, including water treatment and metal finishing.

- Customization: We offer tailored solutions to meet specific customer requirements, ensuring optimal performance in any application.

Technical Features

- Corrosion Resistance: Our Lead Dioxide Electrode exhibits exceptional resistance to chemical corrosion, ensuring longevity and reliability.

- Thermal Stability: Capable of functioning effectively under varying temperature conditions, our electrodes maintain performance without degradation.

- High Activity: The lead dioxide coating is designed to facilitate rapid electrochemical reactions, improving overall efficiency.

Product Application

Our purduct is extensively used in:

1. Electroplating

2. Electrolytic deposition

3. Electrosynthesis

4. Sodium hypochlorite production

5. Wastewater treatment

6. Hydrogen production

7. Laboratory electrolytic cell

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our Lead dioxide electrode production process adheres to strict international standards to ensure quality and efficiency:

Raw Material Sourcing: Only the highest quality lead dioxide is used.

Manufacturing: State-of-the-art facilities ensure precise and consistent electrode formation.

Quality Control: Each batch undergoes rigorous testing to meet industry specifications.

Packaging and Shipping: Secure packaging and reliable logistics for timely delivery.

Quality Inspection

We implement a strict quality management system that includes:

- Incoming Material Inspection: Ensuring only the best materials are used.

- In-Process Quality Checks: Monitoring production at various stages to maintain quality.

- Final Product Testing: Each electrode is tested for performance and durability before shipping.

Packaging Method

Our packaging is designed to protect the electrodes during transportation. We utilize durable, moisture-resistant materials, ensuring that products arrive at their destination in perfect condition.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers exhaustive OEM administrations, giving modified arrangements that meet the exceptional particulars of our accomplices. Our ability traverses the whole item improvement process, from introductory item plan to bundling and last conveyance. We team up intimately with our accomplices to comprehend their particular necessities and inclinations, guaranteeing that each part of the item lines up with their prerequisites. Our group uses trend setting innovation and industry best practices to make excellent items that hang out on the lookout. Moreover, we are focused on keeping up with open correspondence in the meantime, considering adaptability and changes on a case by case basis. With Shaanxi Tianyi, you can believe that your venture will be taken care of with impressive skill and care, bringing about arrangements that really upgrade your image and fulfill your clients. Allow us to assist you with rejuvenating your vision!

FAQ

Q1: What is the lifespan of the Lead Dioxide Electrode?

A1: The lifespan typically ranges from 5 to 10 years, depending on usage and maintenance conditions.

Q2: Can the electrodes be customized?

A2: Yes, we offer customizable sizes and specifications to meet your specific needs.

Q3: What are the main applications of the product?

A3: They are primarily used in water treatment, electroplating, and hydrometallurgy.

Q4: How can I ensure the best performance from my electrodes?

A4: Regular maintenance and adherence to recommended operating conditions will maximize performance.

Q5: How do you handle quality assurance?

A5: We employ strict quality control measures throughout the production process, including testing at multiple stages.

Contact Us

For more information about our Lead Dioxide Electrode or to discuss your specific needs, please reach out to us at info@di-nol.com. Our dedicated team is here to assist you!