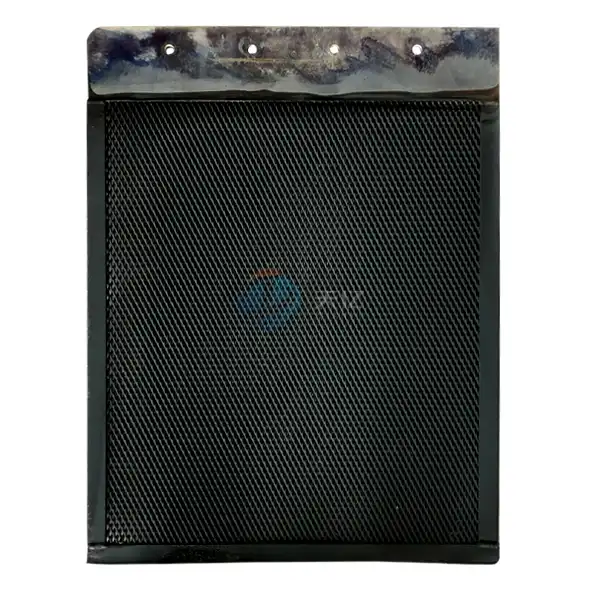

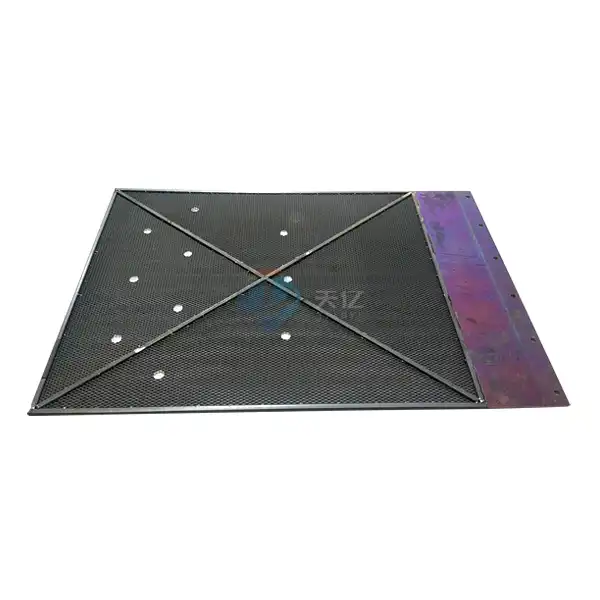

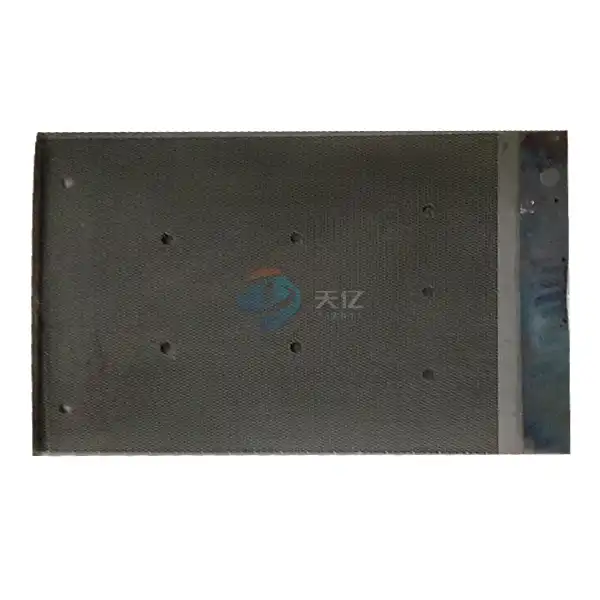

Lead oxide anode

Corrosion resistance

Versatility

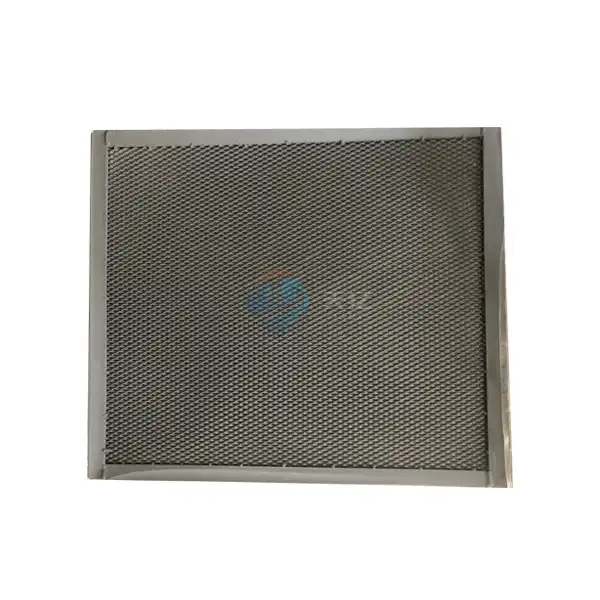

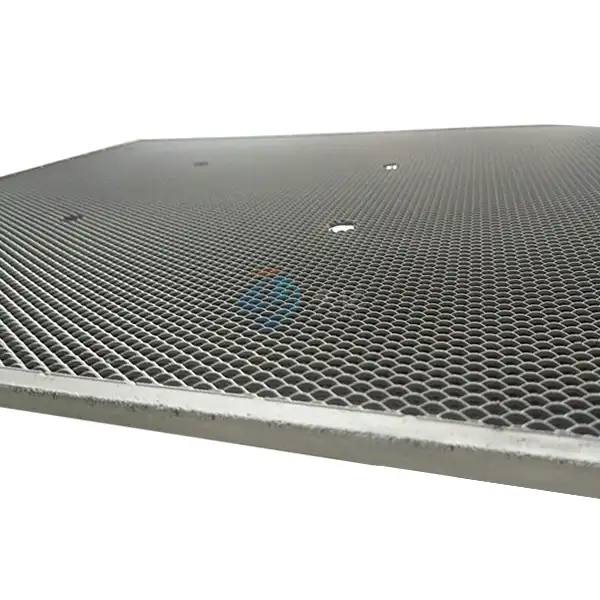

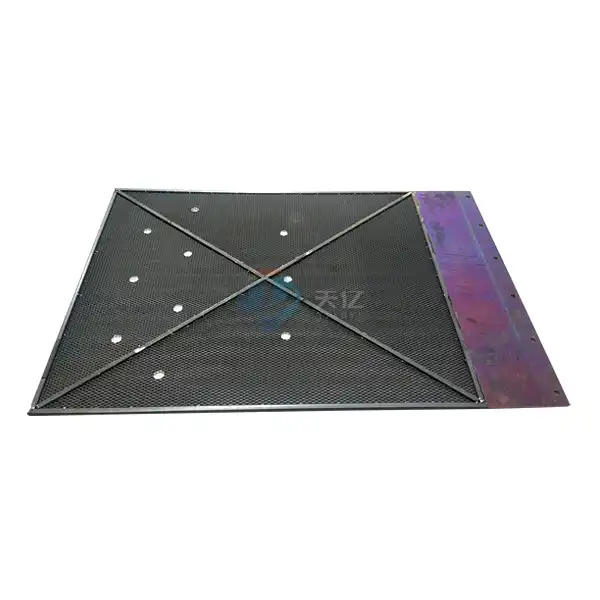

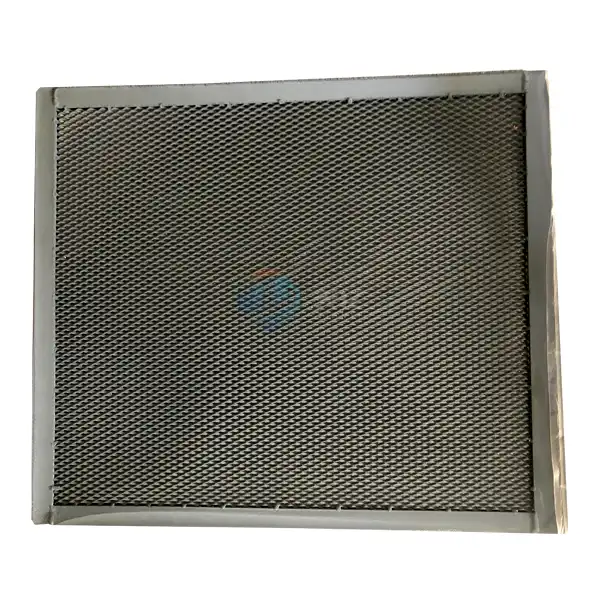

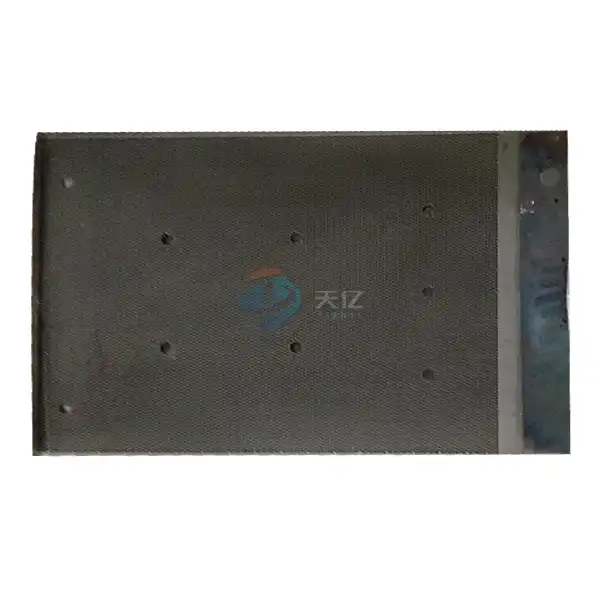

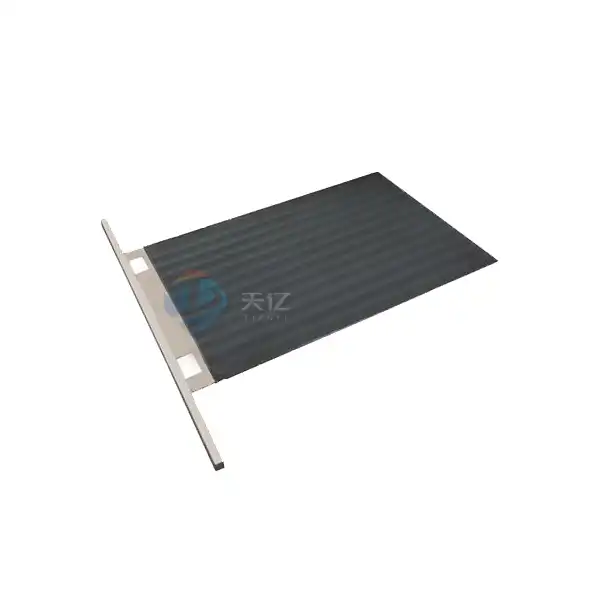

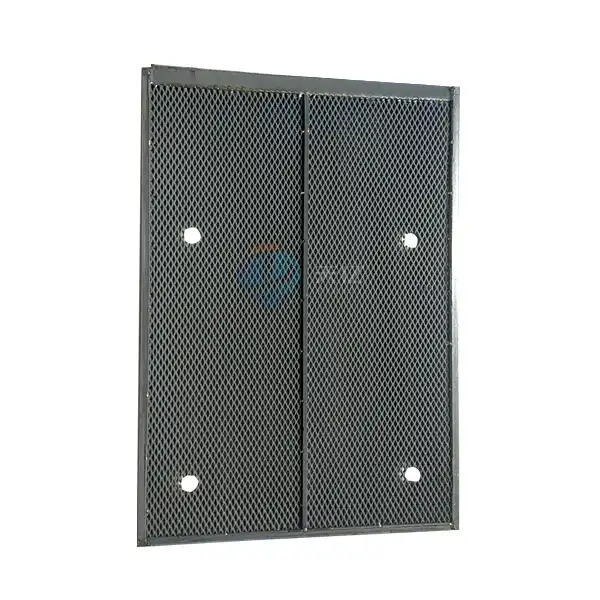

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Lead Oxide Anode Introduction

TianYI's Lead oxide anode offer a superior solution for your battery manufacturing, electronics, and industrial chemical needs. Our anodes are meticulously crafted to deliver exceptional performance and reliability, ensuring consistent quality and efficiency throughout your production processes. We understand the specific demands of the modern market, and our anodes are designed to meet and exceed your expectations. Choose TianYI for guaranteed quality, competitive pricing, and an unwavering commitment to customer satisfaction.

Product Specifications

Parameter | Specification |

Substrate | Gr1/Gr2 Titanium |

Coating Type | Lead dioxide |

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | < 1.13V |

Current Density | < 3000A/M^2 |

Work Time | 80-120 hours |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 1-15μm |

|  |

|  |

Product Composition and Design

Our Lead Oxide Anodes are made from a robust titanium base, coated with high-purity lead oxide to ensure maximum efficiency and longevity. The coating process involves advanced electrochemical techniques, resulting in a uniform and durable layer that enhances performance across various applications.

Product Advantages

- Durability: High resistance to corrosion and degradation.

- Performance: Optimized for excellent electrochemical properties, leading to higher efficiency in applications.

- Customizability: Available in various sizes and specifications to meet specific client requirements.

Technical Features

- High Conductivity: Ensures effective current distribution across the anode surface.

- Thermal Stability: Maintains performance under varying temperatures.

- Low Maintenance: Designed to reduce operational downtime.

Lead oxide anode Application

Lead Oxide Anodes are widely used in:

1. Electroplating

2. Electrolytic deposition

3. Electrosynthesis

4. Sodium hypochlorite production

5. Wastewater treatment

6. Hydrogen production

7. Laboratory electrolytic cell

1. Electroplating 2. Electrolytic deposition 3. Electrosynthesis 4. Sodium hypochlorite production 5. Wastewater treatment 6. Hydrogen production 7. Laboratory electrolytic cellProduct Production Process

Our Lead oxide anode process adheres to strict quality control measures:

Raw Material Sourcing: We select only the highest purity lead to ensure superior product quality.

Controlled Oxidation: Precise oxidation processes to achieve the desired lead oxide properties.

Grinding and Milling: Achieving uniform particle sizes for consistent performance.

Quality Testing: Comprehensive testing at each stage to meet stringent standards.

Packaging and Distribution: Secure packaging ensures safe delivery to your facilities.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Every Lead Oxide Anode undergoes extensive testing, including:

- Visual Inspections: Checking for coating uniformity and defects.

- Performance Testing: Evaluating electrochemical properties to ensure efficiency.

- Durability Testing: Ensuring longevity under operational conditions.

Packaging Method

Our packaging solutions are designed for safety and efficiency, ensuring that products reach customers in pristine condition. We use eco-friendly materials and custom packaging based on client needs, including:

- Foam Inserts: For shock absorption.

- Sealed Containers: To protect against moisture and contamination.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer extensive OEM administrations intended to take care of the assorted necessities of our clients. Our committed group works intimately with clients to foster customized arrangements that meet their particular necessities, guaranteeing that everything about with their vision. From hand crafts that mirror your image personality to specific creation processes that improve proficiency and quality, we invest heavily in our capacity to convey outstanding outcomes. Our cutting edge fabricating offices and talented labor force empower us to create a great many items while keeping up with severe quality control. We focus on correspondence and joint effort all through the task, guaranteeing that we address any worries and make changes on a case by case basis. By picking Shaanxi Tianyi, you gain a dependable accomplice focused on transforming your thoughts into the real world and assisting you with accomplishing your business objectives. Allow us to rejuvenate your vision!

FAQ

1.What is our product?

- Our product is an electrochemical component made from titanium coated with lead oxide, used in various applications for its efficient performance.

2.What are the main applications of the product?

- They are primarily used in electroplating, battery manufacturing, and water treatment processes.

3.How can I customize my Lead oxide anode?

- We offer customization in size, thickness, and specific coatings to meet your project needs.

4.What quality control measures do you have in place?

- Our products undergo rigorous quality checks at each production stage, ensuring durability and performance.

5.What is your lead time for orders?

- Lead times vary based on order size and specifications, but we strive for timely delivery.

Contact Us

For more information or to place an order for our Lead Oxide Anodes, please contact us at info@di-nol.com. Our dedicated team is here to assist you with all your electrochemical material needs. Feel free to reach out if you have any further questions or require additional assistance!