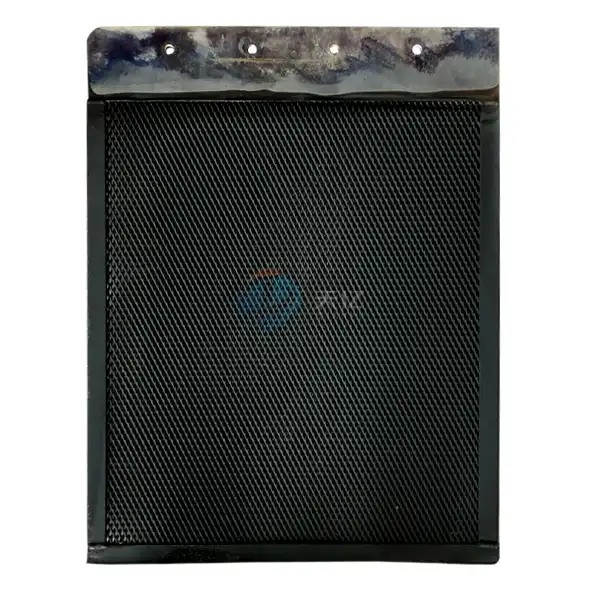

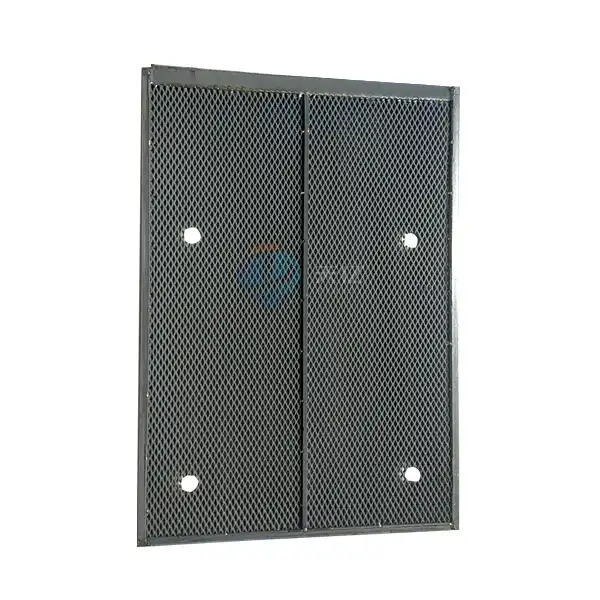

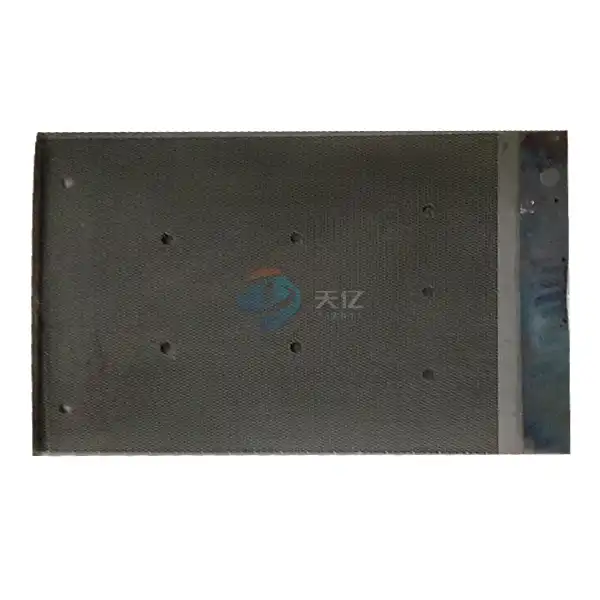

Lead dioxide anode

Corrosion resistance

Versatility

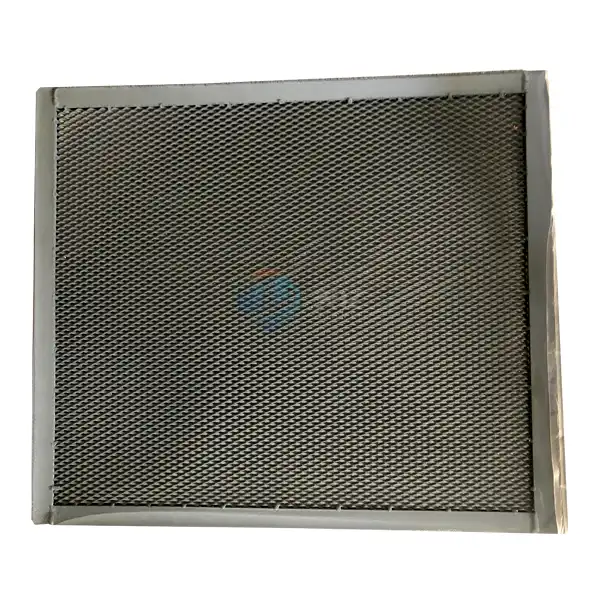

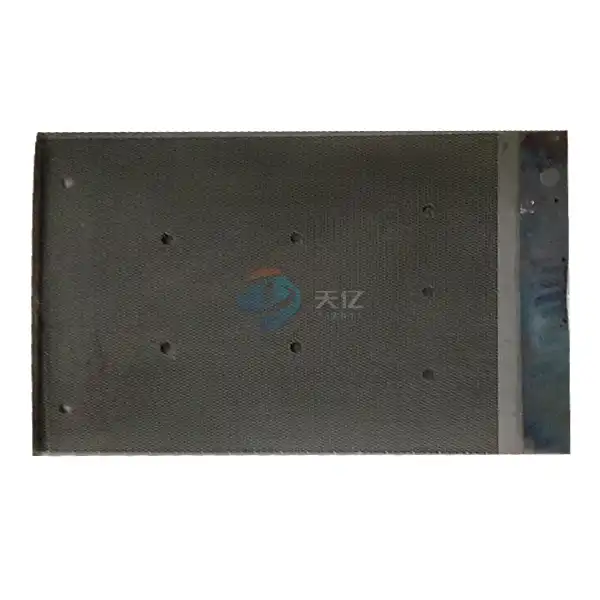

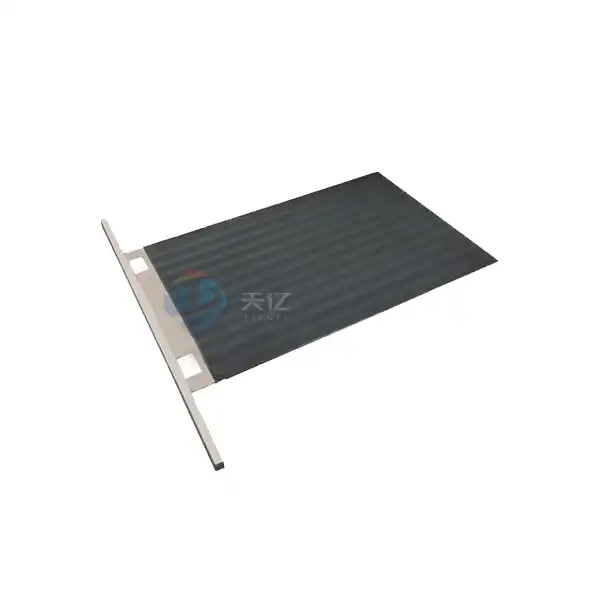

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

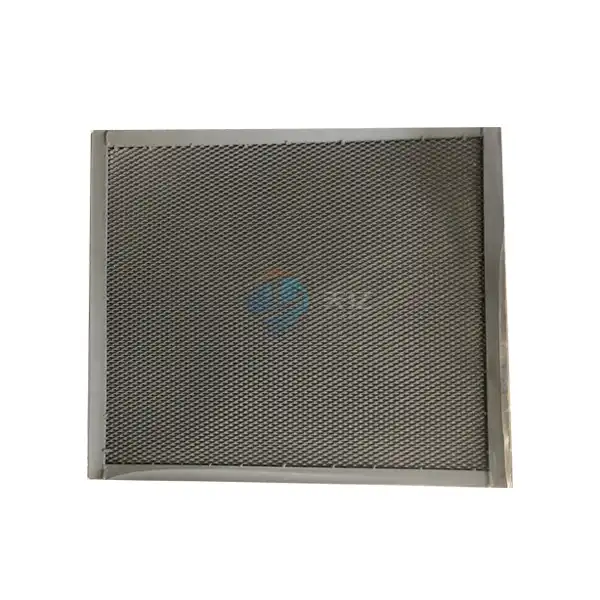

Lead Dioxide Anode Introduction

TianYI's Lead Dioxide Anode stands out with its exceptional quality and innovative design, ensuring superior performance and longevity for your applications. Our anodes deliver high current efficiency and excellent corrosion resistance, reducing your operational costs and increasing productivity. Built with the purest materials and advanced manufacturing processes, our Lead Dioxide Anodes guarantee reliable and consistent results, making them the ideal choice for electroplating, battery manufacturing, and environmental applications. We prioritize consistent quality control and hold international certifications, providing you with a product you can trust to power your success.

Product Specifications

Parameter | Specification |

Substrate | Gr1/Gr2 Titanium |

Coating Type | Lead dioxide |

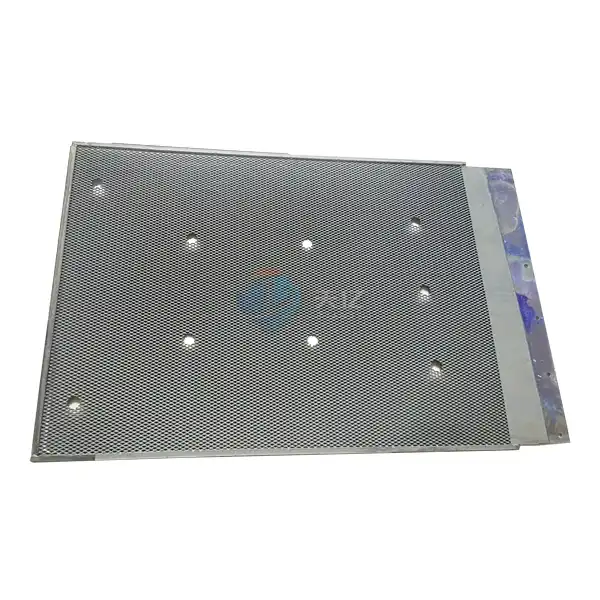

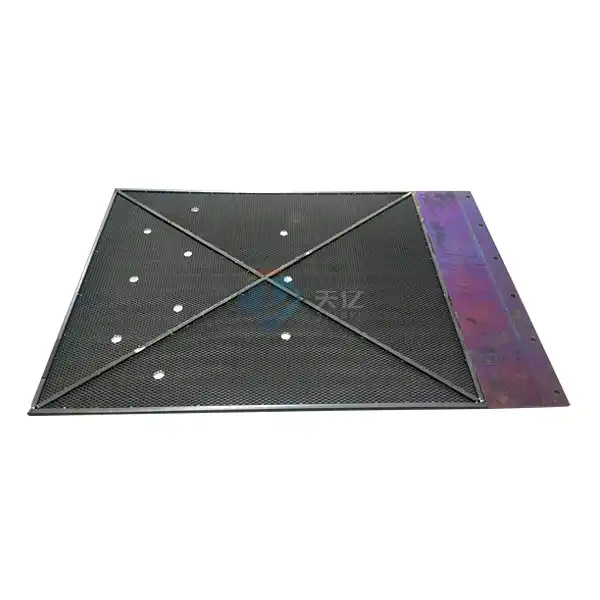

Dimension & Shape | Plate, mesh, rod, or customized |

Voltage | < 1.13V |

Current Density | < 3000A/M^2 |

Work Time | 80-120 hours |

Noble Metal Content | 8-13g/㎡ |

Coating Thickness | 1-15μm |

|  |

|  |

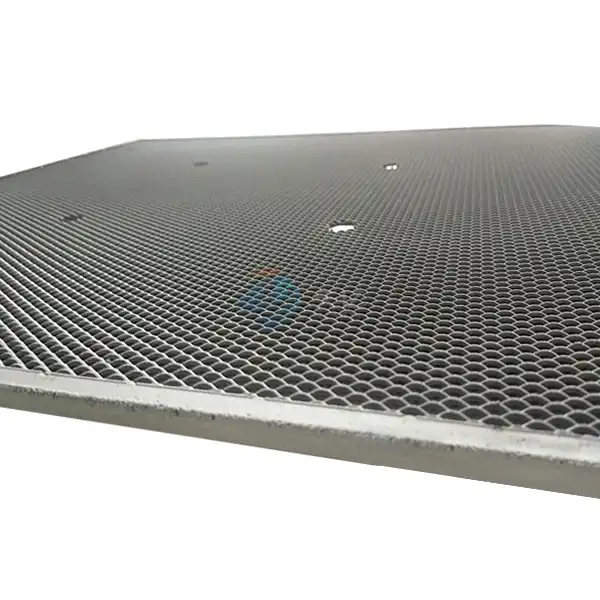

Product Composition and Design

Our Lead Dioxide Anode is constructed from high-grade titanium coated with a robust layer of lead dioxide. This unique composition ensures excellent corrosion resistance and extended service life, even in demanding environments. The design can be tailored to meet specific requirements, allowing us to provide solutions that fit your exact needs.

Product Advantages

- High Durability: The titanium substrate provides exceptional strength and resistance to corrosion, ensuring a longer lifespan for the anode.

- Efficient Performance: Designed for high conductivity, our products facilitate efficient electrochemical reactions.

- Customizable Options: We offer various sizes and thicknesses to meet specific application needs, ensuring optimal performance.

Technical Features

- Stable Operating Conditions: Our products maintain consistent performance under varying operational conditions.

- High Current Efficiency: These anodes provide excellent current efficiency, reducing energy consumption in electrochemical processes.

- Environmentally Friendly: Lead dioxide is a reliable and eco-friendly choice for various applications, promoting sustainability.

Product Application

Lead Dioxide Anodes are widely used in:

1. Electroplating

2. Electrolytic deposition

3. Electrosynthesis

4. Sodium hypochlorite production

5. Wastewater treatment

6. Hydrogen production

7. Laboratory electrolytic cell

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our products undergo a rigorous production process, including:

Raw Material Selection: We begin with sourcing the highest grade Lead Dioxide (PbO2) and substrate materials.

Substrate Preparation: The titanium or tantalum substrate is meticulously cleaned and treated to ensure optimal adhesion.

Coating Application: Advanced techniques are used to apply a uniform layer of Lead Dioxide onto the substrate.

Sintering: The coated anode is sintered under controlled conditions to enhance coating adhesion and durability.

Quality Inspection

Quality is our top priority. We conduct thorough inspections at every stage of production, from raw material evaluation to final product testing. This commitment ensures that our Lead Dioxide Anodes exceed industry benchmarks for performance and reliability.

Packaging Method

Our anodes are packaged securely to prevent damage during transit. Custom packaging options are available to meet specific client needs, ensuring that products arrive in perfect condition.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, allowing businesses to customize their anodes based on specific requirements. Our flexibility ensures that we can meet the diverse needs of our clients, whether for specialized coatings or complete electrochemical systems.

FAQ

Q1: What is the lifespan of the product?

A1: The lifespan can vary based on operating conditions, but with proper maintenance, they can last several years.

Q2: Can you customize the dimensions of the anodes?

A2: Yes, we offer customizable dimensions and thicknesses to meet specific application needs.

Q3: What industries can benefit from using the product?

A3: Industries such as electroplating, water treatment, and cathodic protection are primary users.

Q4: Are there any environmental concerns with using lead dioxide?

A4: We ensure that our products comply with all environmental regulations and promote eco-friendly practices.

Q5: How can I place an order?

A5: Please contact us for pricing and ordering information.

Contact Us

For more information about our Lead Dioxide Anodes or to discuss your specific needs, please reach out to us at [info@di-nol.com]. Our dedicated team is here to assist you and provide tailored solutions for your electrochemical applications. If you have any further requirements or questions, feel free to let me know!