anodic oxide coating titanium

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

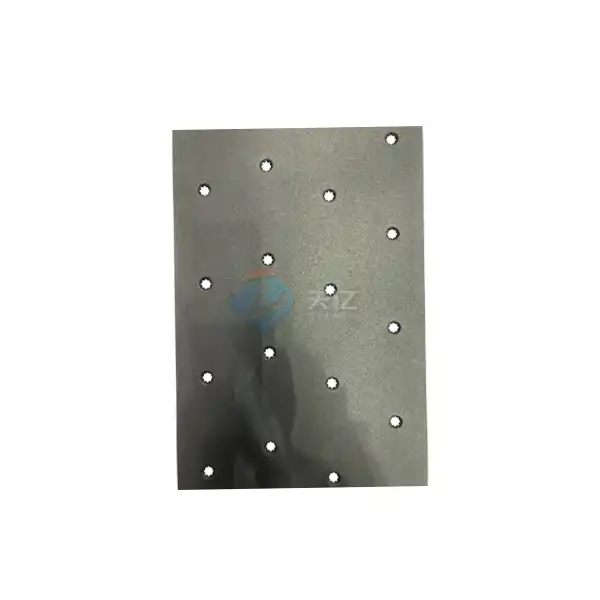

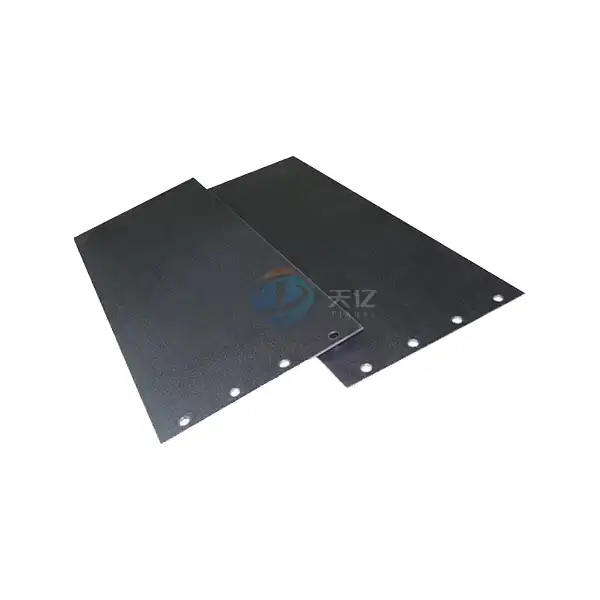

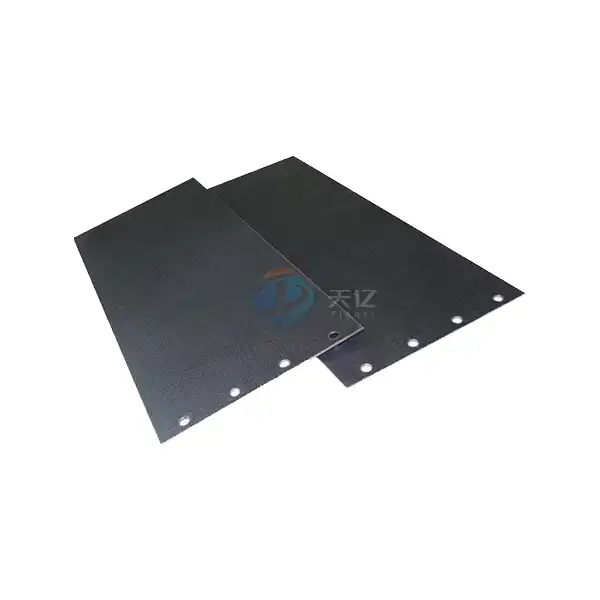

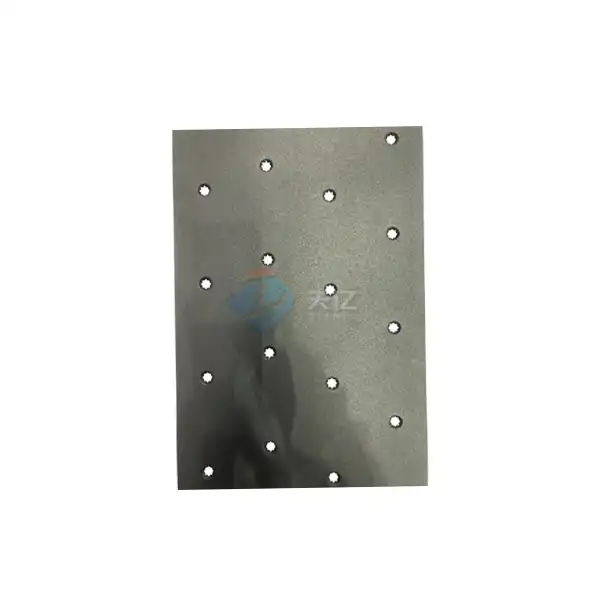

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Anodic oxide coating titanium is a revolutionary advancement in electrochemical technologies, specifically designed to enhance the performance and durability of titanium-based products. This specialized coating process involves applying an oxide layer to titanium surfaces, resulting in improved corrosion resistance and longevity. Whether utilized in industrial electroplating, cathodic protection, or advanced water treatment systems, they stands at the forefront of innovation, making it an essential choice for various applications across multiple industries.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

Anodic oxide coating titanium is composed of a titanium base, often Grade 5 (Ti-6Al-4V) or Grade 23 (Ti-6Al-4V ELI), which is renowned for its high strength and biocompatibility. The anodic layer, primarily composed of titanium dioxide (TiO2), is formed through an electrolytic process that enhances the surface properties of titanium, making it suitable for demanding environments. The design is customizable, allowing for specific coatings that meet the requirements of diverse applications.

Product Advantages

- Enhanced Durability: The anodic oxide coating significantly increases the wear resistance of titanium products, extending their lifespan in harsh conditions.

- Corrosion Resistance: This coating offers superior protection against corrosive substances, ensuring reliability in applications such as water treatment and electroplating.

- Biocompatibility: Ideal for medical applications, it is biocompatible, making it suitable for implants and surgical instruments.

- Customizability: The coating can be tailored to meet specific aesthetic and functional requirements, allowing for flexibility in design.

Technical Features

- High Temperature Stability: The anodic oxide layer can withstand extreme temperatures without degrading, making it suitable for high-performance applications.

- Electrical Insulation: The coating provides excellent electrical insulation, crucial for certain electrochemical processes.

- Chemical Stability: Resistant to a wide range of chemicals, enhancing its suitability for industrial applications.

Product Application

Anodic oxide coating titanium is versatile and is widely used in:

1. Electroplating

2. Aluminum foil production

3. Electrolytic copper foil production

4. Galvanized steel sheet

5. Water treatment

6. Cathodic protection

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

The production of the product involves several critical steps:

Titanium Substrate Selection

High-grade titanium substrates are chosen based on their purity and mechanical properties. The selection of the appropriate titanium alloy is critical for achieving optimal anodic oxide coating performance.

Surface Cleaning

The titanium surfaces undergo a meticulous cleaning process to eliminate contaminants. This typically includes degreasing with solvents and ultrasonic cleaning, ensuring a clean surface for effective anodization.

Anodizing Electrolyte Preparation

A specific anodizing electrolyte solution is prepared, usually consisting of sulfuric acid, oxalic acid, or other suitable electrolytes. The concentration and temperature are optimized to enhance the anodizing reaction.

Anodizing Process Setup

The titanium substrate is submerged in the electrolyte and connected to the power supply as the anode. A cathode is placed in the electrolyte solution, and the system is configured for the anodizing process.

Application of Electric Current

An electric current is applied, initiating the anodizing reaction. The voltage and duration are carefully controlled to facilitate the growth of the anodic oxide layer, ensuring it meets the required thickness and quality.

Post-Anodizing Rinse

After anodization, the coated titanium is thoroughly rinsed with distilled water to remove residual electrolyte and prevent contamination of the anodic layer. This step is crucial for maintaining the integrity of the oxide coating.

Quality Assessment

The anodic oxide coating undergoes quality assessment through various tests, including thickness measurement, adhesion tests, and corrosion resistance evaluations. These tests ensure compliance with industry standards and specifications.

Final Packaging

Once quality assurance is complete, the anodized titanium products are packaged in protective materials to prevent damage during transportation. Each package includes relevant product documentation, handling instructions, and safety information for end users.

Quality Inspection

Quality assurance is paramount at Shaanxi Tianyi. Each batch of anodic oxide coated titanium undergoes rigorous inspection processes, including:

- Material Testing: Ensuring that raw materials meet industry standards.

- Thickness Measurement: Confirming the uniformity of the coating.

- Corrosion Resistance Testing: Evaluating performance in simulated environments.

Packaging Method

We prioritize the safe transportation of our products. Anodic oxide coating titanium is packaged using:

- Custom Foam Inserts: Protecting products during transit.

- Sealed Containers: Ensuring contamination-free delivery.

- Environmentally Friendly Materials: Committed to sustainability in our packaging choices.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services, providing tailored solutions to meet your specific needs. Our team collaborates closely with clients to develop custom products that align with their operational requirements.

FAQ

1. What industries can benefit from the product?

- It is widely used in electroplating, water treatment, and medical fields.

2. How does anodic oxide coating improve titanium’s performance?

- The coating enhances corrosion resistance and durability, making it suitable for harsh environments.

3. Can I get custom sizes and colors for the product?

- Yes, we offer customization options for both dimensions and color finishes.

4. What is the lead time for orders?

- Typically, orders are processed within 4-6 weeks, depending on specifications.

5. Do you provide samples before bulk orders?

- Yes, we can provide samples for evaluation upon request.

Contact Us

For more information or to request a quote on anodic oxide coating titanium, please reach out to us at info@di-nol.com. We look forward to assisting you with your electrochemical material needs!