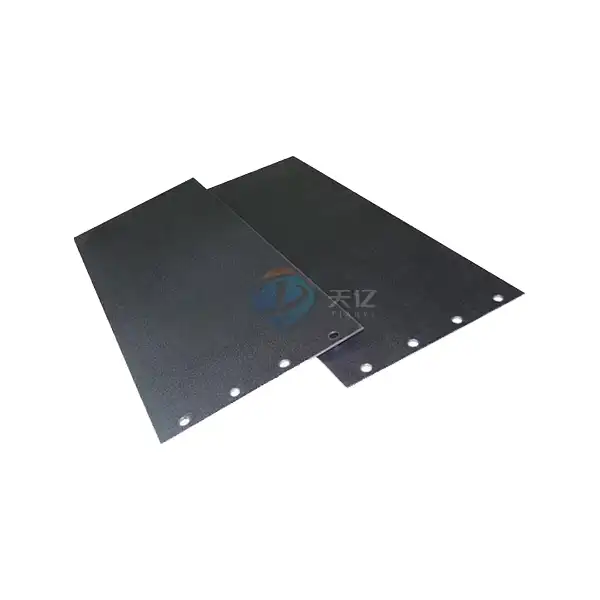

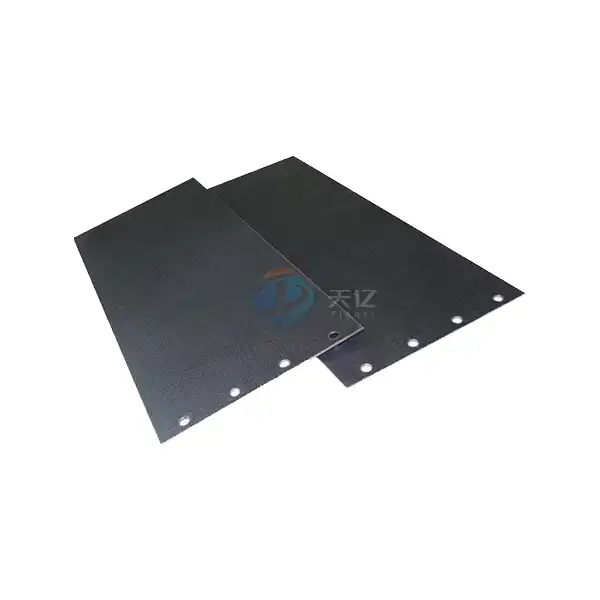

Ir-Ta coated titanium oxide anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Ir-Ta Coated Titanium Oxide Anode Introduction

Ir-Ta coated titanium oxide anode is widely considered the optimal choice across various industries due to their exceptional corrosion resistance in acidic media, low oxygen evolution overpotential, excellent physical stability, and environmental safety. In comparison to conventional electrodes, these Ir-Ta mixed metal oxide (MMO) electrodes exhibit superior electrochemical stability in sulfate/chloride solutions and extended service life. Our electrodes find applications in copper foil production, electroplating, cathodic protection, organic synthesis, acid solution electrolysis, and electrowinning.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

The Ir-Ta Coated Titanium Oxide Anode features a unique composition that enhances its performance and longevity. The base titanium substrate provides excellent strength and corrosion resistance, while the Ir-Ta coating ensures high electrical conductivity and catalytic activity. This combination not only increases the anode's efficiency but also extends its operational life.

Product Advantages

- High Performance: Exceptional durability and resistance to corrosion, making it suitable for harsh environments.

- Long Service Life: Designed to last up to 10 years, reducing the need for frequent replacements.

- Customizable: Tailored to meet specific client requirements regarding size and application.

Technical Features

- Superior Electrochemical Activity: Enhances efficiency in electrochemical reactions, leading to reduced energy consumption.

- Wide Application Range: Suitable for various industries including electroplating, water treatment, and cathodic protection.

- Environmental Compliance: Manufactured in adherence to sustainable practices, contributing to global environmental protection efforts.

Ir-Ta Coated Titanium Oxide Anode Application

The Ir-Ta Coated Titanium Oxide Anode is widely used in:

1. Water Treatment

Electrochemical Chlorination: Ir-Ta coated titanium oxide anodes are used to generate chlorine from seawater or brine for water disinfection.

Wastewater Treatment: They help in breaking down pollutants and organic compounds through processes like electrochemical oxidation.

Electrocoagulation: Effective in removing heavy metals and contaminants from water.

2. Metal Recovery and Electroplating

Electroplating: These anodes ensure uniform deposition of metals such as gold, platinum, and nickel.

Metal Recovery: Used in recovering precious and heavy metals from industrial effluents and mining operations.

3. Chemical Production

Chlor-Alkali Process: Produces chlorine and caustic soda by electrolyzing brine. Ir-Ta anodes are highly resistant to chlorine corrosion, making them ideal for this application.

Hydrogen Production: Applied in water electrolysis to generate hydrogen in green energy initiatives.

4. Cathodic Protection

Protects steel structures such as pipelines, storage tanks, and offshore platforms from corrosion by acting as a durable anode in impressed current cathodic protection (ICCP) systems.

5. Organic and Inorganic Synthesis

Used in the electrochemical synthesis of organic compounds, including pharmaceuticals and dyes.

Facilitates the production of persulfates and other oxidizing agents in inorganic chemical processes.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process for the Ir-Ta Coated Titanium Oxide Anode is meticulously optimized to ensure quality and consistency:

Substrate Material Selection

High-purity titanium substrates are selected for their excellent mechanical properties and resistance to corrosion. The choice of titanium grade is crucial for ensuring long-lasting performance in electrochemical environments.

Surface Cleaning and Activation

The titanium surfaces are cleaned using solvents to remove any grease or contaminants. They are then subjected to surface activation processes, such as sandblasting and acid etching, to enhance surface roughness and promote better adhesion for the oxide coating.

Preparation of Iridium and Tantalum Oxides

High-purity iridium and tantalum compounds are prepared to create the oxide coating. These materials are often mixed in specific ratios to achieve optimal electrochemical properties and stability for the intended application.

Coating Application

The Ir-Ta oxide mixture is applied to the prepared titanium substrate using electrochemical deposition or thermal spray methods. Precise control of application parameters ensures a uniform and consistent coating thickness across the substrate.

Curing and Bonding

Following the application, the coated anodes are subjected to a heat treatment process. This curing step promotes the formation of strong bonds between the titanium substrate and the oxide layer, enhancing adhesion and durability.

Electrochemical Testing

The Ir-Ta coated titanium oxide anodes undergo thorough electrochemical performance testing, assessing factors like catalytic activity, current efficiency, and stability under operational conditions. This ensures that the anodes meet rigorous performance standards.

Final Quality Control

After testing, the coated anodes are inspected for defects, such as coating uniformity and surface imperfections. This final quality control step is vital to guarantee that only high-quality products are approved for distribution.

Packaging and Documentation

Once the anodes pass quality inspections, they are packaged in protective materials to prevent damage during transport. Accompanying documentation includes product specifications, usage instructions, and safety guidelines for end users.

Quality Inspection

At Shaanxi Tianyi, we believe in delivering products that exceed industry benchmarks. Our quality inspection process includes:

- Continuous monitoring during production.

- Comprehensive testing of finished products for performance and reliability.

Packaging Method

At Shaanxi Tianyi, we place a strong emphasis on safety and cost-effectiveness in our packaging solutions. Our product is packaged with care, using high-quality materials and protective designs to prevent any damage during transit. This meticulous approach ensures that each anode arrives in perfect condition, ready for immediate use. We understand that reliable packaging not only protects the product but also enhances customer satisfaction by minimizing delays and potential losses. By prioritizing both safety and efficiency, we demonstrate our commitment to delivering exceptional products that meet the needs of our clients.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi provides comprehensive OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services designed to meet the specific needs of our clients. We collaborate closely with our partners to develop customized solutions that enhance product performance and ensure long service life. Our focus on quality and innovation helps us deliver reliable products that support our clients’ success in a competitive market.

FAQ

Q1: What is the service life of the product?

A1: The service life can reach up to 10 years, depending on the operating conditions.

Q2: Can I customize the dimensions of the anodes?

A2: Yes, we provide fully customizable options to meet your specific requirements.

Q3: What industries can benefit from using these anodes?

A3: They are suitable for various industries, including electroplating, water treatment, and cathodic protection.

Contact Us

For more information about our Ir-Ta Coated Titanium Oxide Anode, please contact us at [info@di-nol.com]. Our dedicated team is here to assist you with any inquiries or customization needs.

YOU MAY LIKE

VIEW MOREIridium tantalum oxide anode

VIEW MOREIridium tantalum oxide anode VIEW MOREIr-Ta oxide coated DSA electrode

VIEW MOREIr-Ta oxide coated DSA electrode VIEW MOREdsa coating titanium anode

VIEW MOREdsa coating titanium anode VIEW MOREmmo coated titanium anodes for cathodic protection

VIEW MOREmmo coated titanium anodes for cathodic protection VIEW MOREIr-Ta coated titanium anode

VIEW MOREIr-Ta coated titanium anode VIEW MORETitanium Anode For Electrodialysis

VIEW MORETitanium Anode For Electrodialysis VIEW MOREanodic oxide coating titanium

VIEW MOREanodic oxide coating titanium VIEW MOREanodic coating titanium

VIEW MOREanodic coating titanium