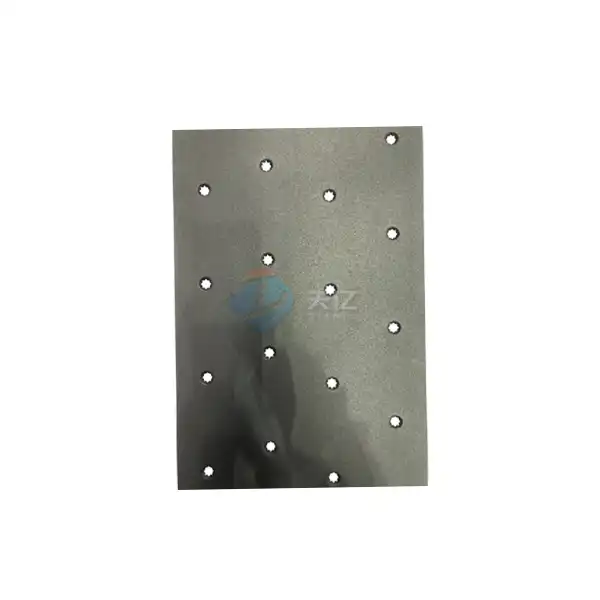

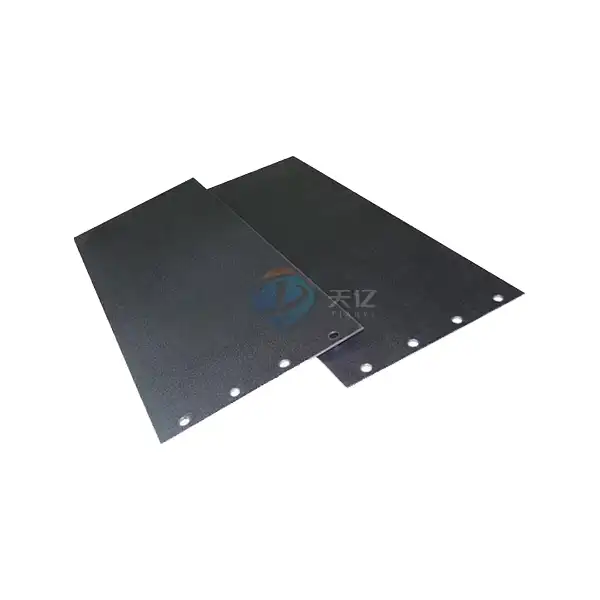

Ir-Ta coated titanium anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Ir-Ta Coated Titanium Anode Introduction

An Ir-Ta coated titanium anode is an electrode coated with an iridium and tantalum oxide film that's used in a variety of industries:

Corrosion resistance

Ir-Ta coated titanium anode is resistant to corrosion in acidic environments.

Electrochemical stability

They have better electrochemical stability in sulfate and chloride environments than traditional electrodes.

Service life

They have a long service life, typically two to five years.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

Our Ir-Ta coated titanium anode feature a robust titanium base, providing excellent mechanical strength and corrosion resistance. The iridium-tantalum coating enhances the anode's electrochemical performance, making it ideal for demanding environments such as electroplating, cathodic protection, and water treatment.

Product Advantages

- High Efficiency: Our anodes provide superior electrochemical performance, resulting in lower energy consumption.

- Longevity: The durable coatings extend the service life of the anodes, reducing replacement costs.

- Customizable Solutions: We tailor our products to meet the specific needs of each client, ensuring optimal performance.

- Environmental Compliance: Our manufacturing processes adhere to stringent environmental standards, promoting sustainability.

Technical Features

- Low Overpotential: Our Ir-Ta coated anodes exhibit low overpotential, enhancing current efficiency.

- Stable Performance: They maintain consistent performance across various operating conditions.

- Rapid Response: Quick response to changes in operational parameters ensures optimal process control.

Product Application

Ir-Ta coated titanium anodes are widely used in various industries, including:

1. Electroplating

2. Aluminum foil production

3. Electrolytic copper foil production

4. Galvanized steel sheet

5. Water treatment

6. Cathodic protection

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Quality Inspection

We maintain a comprehensive quality control system, including:

- Incoming Material Inspection: Thorough testing of raw materials for quality assurance.

- In-Process Monitoring: Regular checks during production to ensure adherence to specifications.

- Final Product Testing: Extensive evaluation of finished products to verify performance and durability.

Packaging Method

Our packaging solutions are designed to protect products during transport and handling:

- Safety Packaging: Each anode is securely packaged to prevent damage.

- Custom Packaging Options: Available upon request to meet specific client requirements.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer tailored OEM services, providing customized Ir-Ta coated titanium anodes designed to meet your unique specifications and applications. Our dedicated team collaborates closely with you throughout the process, ensuring that every detail aligns with your exact needs. By understanding your operational requirements, we deliver high-performance anodes that enhance efficiency and durability. With our advanced coating techniques and stringent quality control, we guarantee that the final product exceeds your expectations and supports the success of your projects. Whether you need specific dimensions or specialized features, we are committed to providing innovative solutions that drive your business forward.

FAQ

1. What is the lifespan of an Ir-Ta coated titanium anode?

The lifespan varies based on operating conditions but typically exceeds 5 years with proper maintenance.

2. Can I customize the dimensions of the anodes?

Yes, we offer customizable diameters and lengths to meet your specific requirements.

3. What industries benefit from using Ir-Ta coated titanium anodes?

They are widely used in electroplating, water treatment, cathodic protection, and more.

4. How do I place an order?

You can contact us directly via email at [info@di-nol.com] to discuss your requirements.