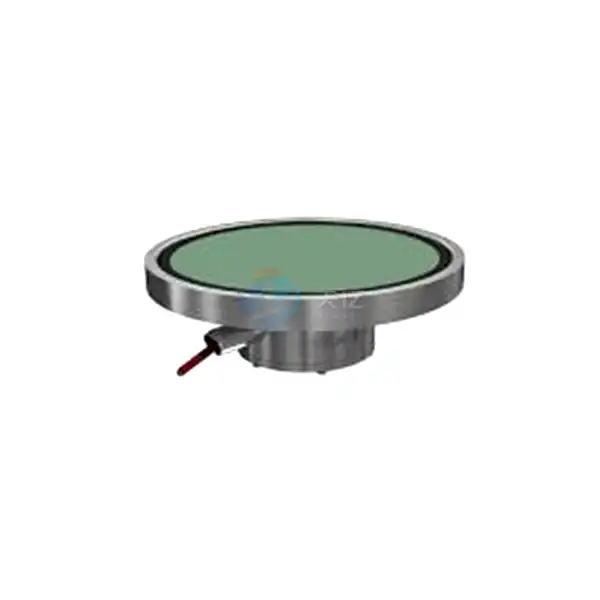

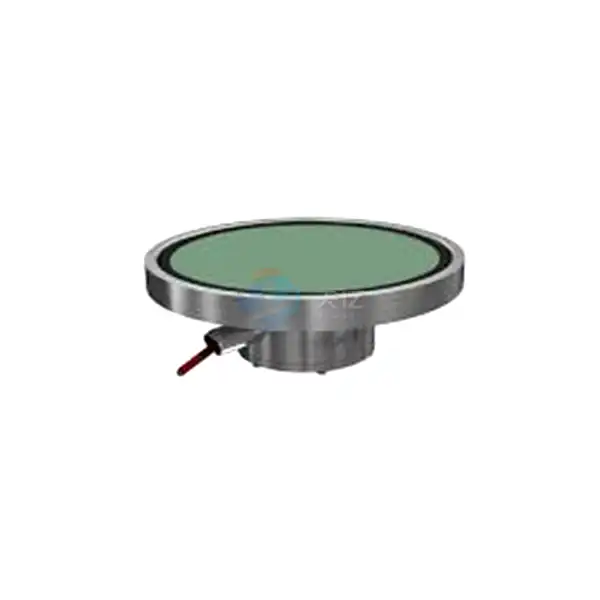

Elliptical Vessel Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., where we proudly present our Elliptical Vessel Anode. This innovative product is designed for optimal electrochemical performance in various applications, including water treatment, electroplating, and cathodic protection. Crafted from high-quality MMO (Mixed Metal Oxide) coated titanium, our elliptical anodes deliver exceptional durability and efficiency, ensuring that your electrochemical processes run smoothly.

Product Specifications

Substrate | Titanium Gr1 |

Coating | Iridium Oxide (IrO2), Ruthenium Oxide (RuO2), Tantalum Oxide (Ta2O5) |

Shape | Disc or Disk |

Diameter | φ25, φ60, φ100, φ150, |

Application | water tanks, Pressure Vessels, Oil and Gas Pipeline, Vessels |

Design Life | Specified 20-100 years |

Environment | Seawater environments/Marine Structures |

|  |

|  |

Product Composition and Design

Our Elliptical Vessel Anode is composed of premium-grade titanium coated with a mixture of ruthenium and iridium. This unique combination not only enhances the anode’s corrosion resistance but also maximizes its electrochemical activity. The elliptical shape provides increased surface area, allowing for improved current distribution, which is crucial for efficient operation in various applications.

Product Advantages

- High Performance: Enhanced current efficiency and lower voltage requirements lead to energy savings.

- Long Lifespan: Designed for extended service life with minimal degradation.

- Versatility: Suitable for a wide range of applications, including industrial electroplating and water treatment.

- Eco-Friendly: Our products are manufactured with sustainable practices, contributing to environmental protection.

Technical Features

- Corrosion Resistance: The MMO coating provides exceptional resistance to corrosive environments, ensuring reliability in harsh conditions.

- Custom Design Options: We offer customizable shapes and sizes to meet specific customer requirements.

- Efficient Electrochemical Activity: Optimized design for maximum electrochemical performance and minimal energy consumption.

Product Application

The Elliptical Vessel Anode is ideal for various applications, including:

Marine Structures: MMO disc anodes are widely used to protect marine structures such as ship hulls, docks, piers and offshore platforms. They counteract the corrosive effects of seawater on these structures.

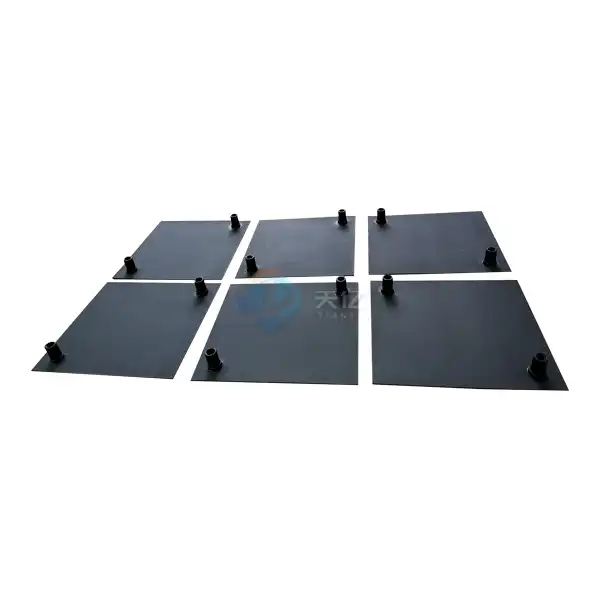

Storage Tanks: They can be used on the bottom of above-ground storage tanks, on the outside of underground tanks to prevent corrosion.

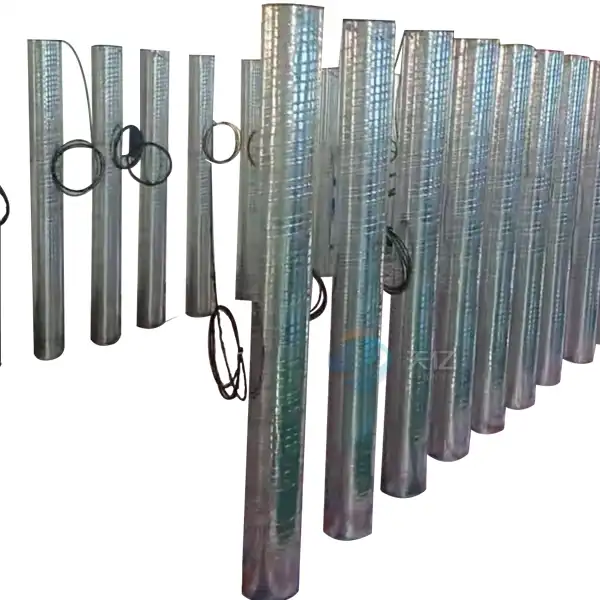

Pipelines: MMO disc anodes are used to protect both onshore and offshore pipelines, ensuring they are protected from corrosion throughout their service life.

Water Treatment Facilities: They are also used in water treatment plants and desalination facilities to protect equipment from corrosive elements in the water.

Reinforced Concrete Structures: MMO disc anodes can be used to protect the steel reinforcement within concrete structures, preventing corrosion of the steel, thereby extending the service life of the structure.

Cooling Systems: In industrial cooling systems, MMO disc anodes can help protect infrastructure from the corrosive effects of coolants.

Electrochlorination Systems: They play a role in the production of chlorine from salt water, a process called electrochlorination.

Heat Exchangers: They can be used to protect heat exchangers from the corrosive effects of the fluids they handle.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process ensures the highest quality standards:

Material Selection

The production of elliptical vessel anodes begins with selecting high-quality materials. Titanium is commonly used due to its excellent corrosion resistance, high strength-to-weight ratio, and ability to withstand harsh electrolytic environments.

Design Specifications

Engineers create detailed design specifications for the elliptical vessel anode, including dimensions, thickness, and overall shape. CAD software is often used to simulate the design and ensure it meets performance requirements.

Sheet Cutting

Large titanium sheets are cut into the desired elliptical shape using advanced techniques like laser cutting or CNC machining. This ensures precision in the dimensions and a clean edge finish, which is vital for effective welding and assembly.

Forming and Shaping

The cut titanium sheets are then subjected to forming processes, such as hydraulic pressing or rolling, to achieve the elliptical contour required for the vessel anode. This step is crucial for maintaining structural integrity and ensuring proper fit within the intended application.

Welding

The formed pieces are welded together using TIG (Tungsten Inert Gas) welding techniques, which provide strong, high-quality joints. Special care is taken to prevent contamination during the welding process, as impurities can affect the anode's performance.

Surface Treatment

After welding, the elliptical vessel anode undergoes surface treatment to enhance its performance. This may involve cleaning, passivation, or surface roughening processes to improve adhesion for the subsequent coating.

Coating Application

The next step involves applying a protective and conductive coating, often consisting of mixed metal oxides. This can be accomplished through dip coating, spray coating, or electrochemical deposition, ensuring a uniform layer across the anode's surface.

Curing and Drying

Once the coating is applied, the anode is subjected to a curing process, typically involving heating to specific temperatures. This enhances the bond between the coating and the titanium substrate, ensuring durability and longevity in operation.

Quality Assurance

Each elliptical vessel anode undergoes rigorous quality assurance checks, which include evaluating the coating thickness, adhesion, and overall structural integrity. Testing is conducted to ensure that the anode meets industry standards and customer specifications.

Final Inspection

Before packaging, the anodes undergo a comprehensive final inspection to identify any defects in the shape, surface finish, or coating. This ensures that only high-quality products are dispatched to customers.

Packaging

The finished elliptical vessel anodes are packaged with care to prevent damage during transport. Each package is labeled with essential information, including product specifications, handling instructions, and compliance certifications.

Documentation

Accompanying the anodes is detailed documentation that includes specifications, installation guidelines, and operational instructions. This ensures customers have all necessary information for proper use and maintenance.

Shipping

Finally, the packaged elliptical vessel anodes are shipped to customers using reliable logistics providers. Tracking systems are employed to monitor delivery and ensure timely arrival.

This meticulous production process ensures that elliptical vessel anodes are manufactured to the highest standards, providing exceptional performance in a variety of electrolytic applications.

Quality Inspection

At Shaanxi Tianyi, we prioritize quality. Each Elliptical Vessel Anode undergoes stringent inspections, including:

- Material testing for purity and composition.

- Coating thickness verification.

- Performance testing under operational conditions.

Packaging Method

We employ custom packaging solutions that prioritize safety and cost-effectiveness. Each anode is securely packaged to prevent damage during transit, ensuring that it reaches you in perfect condition.Our commitment to safety and efficiency in packaging does not end with the physical packaging itself. We also monitor environmental conditions to protect sensitive goods from factors such as extreme temperatures or moisture .

OEM Service

We offer comprehensive OEM services tailored to your specific needs. Whether you require unique designs, customized coatings, or specific packaging, our team is here to help.We also monitor environmental conditions to protect sensitive goods from factors such as extreme temperatures or moisture .

FAQ

1. What is the lifespan of the product?

- The service life can exceed 10 years, depending on operational conditions.

2. Can the anodes be customized?

- Yes, we provide customizable shapes and sizes to fit your requirements.

3. What industries can benefit from using these anodes?

- Industries such as water treatment, electroplating, and cathodic protection can greatly benefit from our anodes.

4. How are the anodes packaged for delivery?

- Our anodes are packaged with safety in mind, using secure materials to prevent damage during transport.

5. What is your return policy?

- We offer a customer-friendly return policy. Please contact our support team for specific inquiries.

Contact Us

For more information about our Elliptical Vessel Anode or to discuss your specific requirements, please reach out to us at [info@di-nol.com]. Our dedicated team is ready to assist you with all your needs!