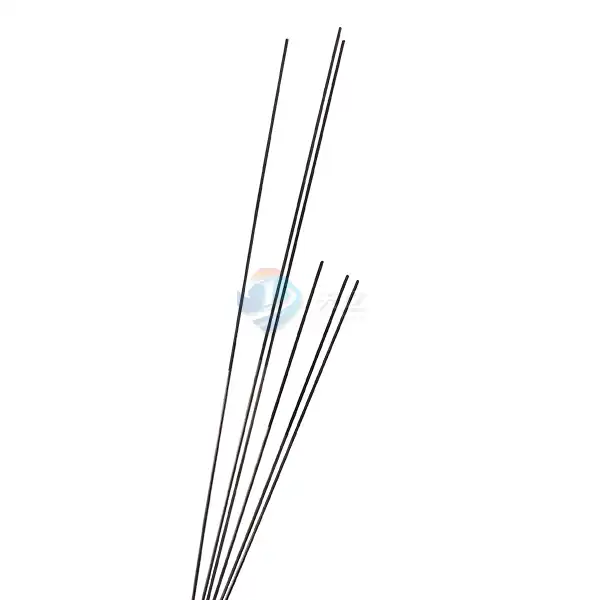

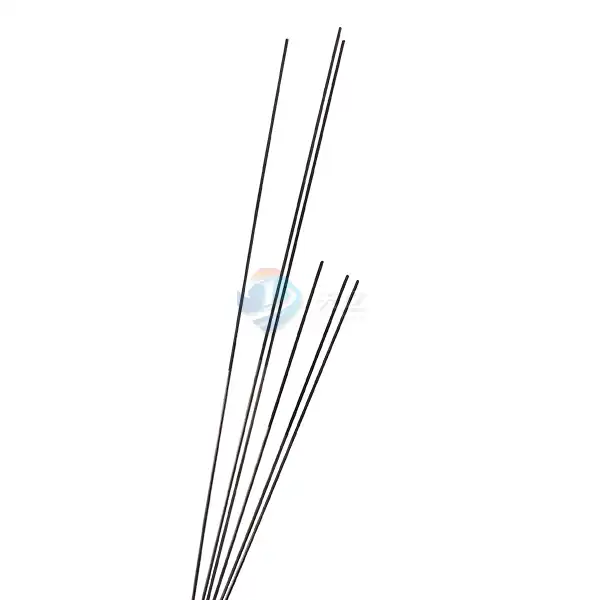

Wire Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Wire Anode Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., where we specialize in high-performance wire anodes designed for a variety of electrochemical applications. Our products are crafted from advanced MMO (Mixed Metal Oxide) coated titanium, ensuring superior durability, corrosion resistance, and efficiency. These products are essential for industries ranging from water treatment to electroplating, providing reliable solutions that meet the highest standards.

Product Specifications

productparameter | ||

Electrolytes | Withstand current density (A/m2) | Life expectancy (years) |

Carbon filler | 50 | 20 |

Calcined coke | 100 | 20 |

freshwater | 100 | 20 |

silt | 100 -300 | 20 |

seawater | 600 | 20 |

Diameter(mm) length can be customized | Coating Type | Output current (mA/m) | Design life (years) |

1.5 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 328 | 20-50 |

2 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 500 | 20-50 |

3 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 656 | 20-50 |

|  |  |

|  |  |

Product Composition and Design

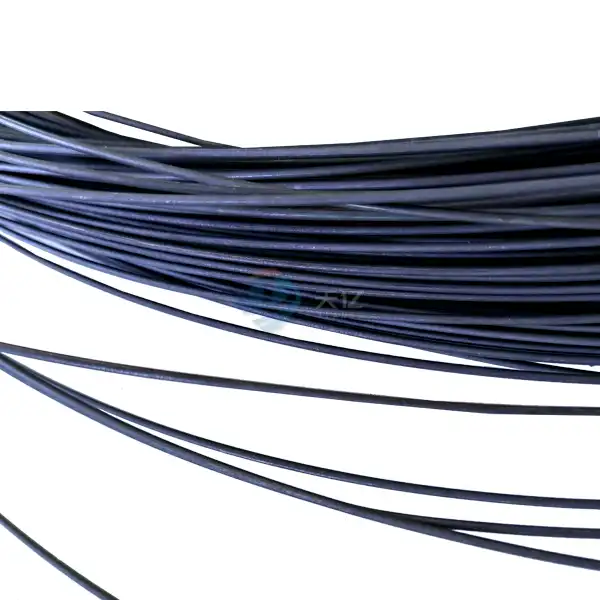

Our wire anodes are designed with a unique composition that maximizes performance. The core is made from high-quality titanium, known for its excellent strength-to-weight ratio and resistance to corrosion. The MMO coating is meticulously applied, enhancing the anode's electrochemical properties, making it highly effective in various applications.

Product Advantages

- High Efficiency: Our products exhibit superior performance in terms of current efficiency, which translates to better energy savings in electrochemical processes.

- Durability: With a robust construction, our anodes are built to last, ensuring longevity and reliability even in harsh environments.

- Customization: We understand that every application is unique, which is why we offer customizable sizes and specifications to meet your specific needs.

- Eco-Friendly: Our production processes prioritize environmental responsibility, contributing to sustainable industrial practices.

Technical Features

- Corrosion Resistance: The titanium base and MMO coating provide excellent protection against corrosion, ensuring a longer service life.

- Lightweight: Our products are significantly lighter than traditional anodes, making them easier to handle and install.

- Wide Application Range: Suitable for various applications, including water treatment systems, industrial electroplating, and cathodic protection systems.

Product Application

Wire anodes are essential in several industries:

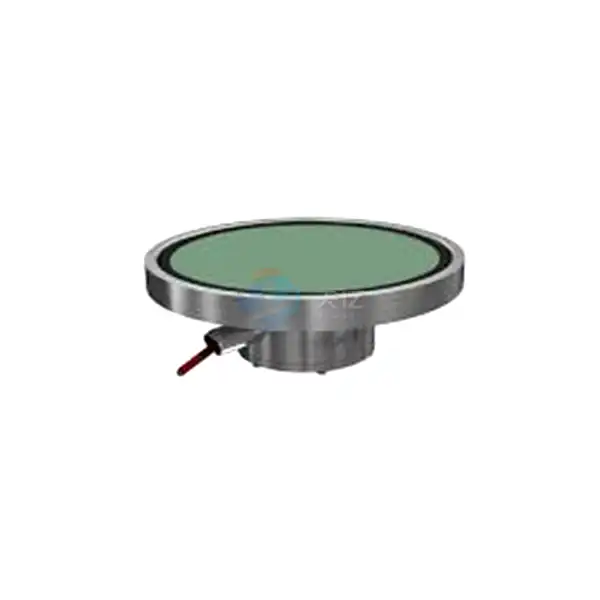

1. Used alone as an auxiliary anode for cathodic protection, or as an MMO electrocatalytic electrode for a cylindrical anode or a flexible anode;

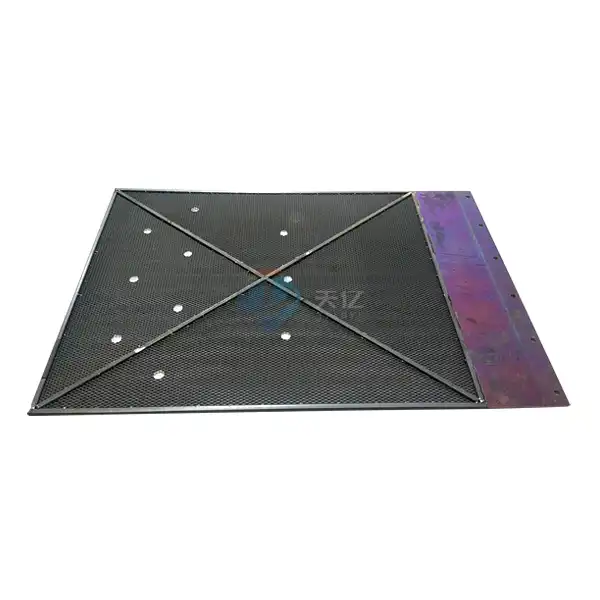

2. Can be used for cathodic protection of continuous horizontal beds, discontinuous vertical surfaces, storage tank equipment, cable protection, water boiling containers, etc.;

3. Can also be used as an auxiliary anode for industrial electroplating and an electrocatalytic oxidation electrode for electrochemical water treatment.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process is rigorous and efficient:

Material Selection

High-quality conductive materials, such as titanium or stainless steel, are selected for wire anodes. These materials are chosen for their excellent corrosion resistance and electrical conductivity, ensuring effective performance in electrolytic applications.

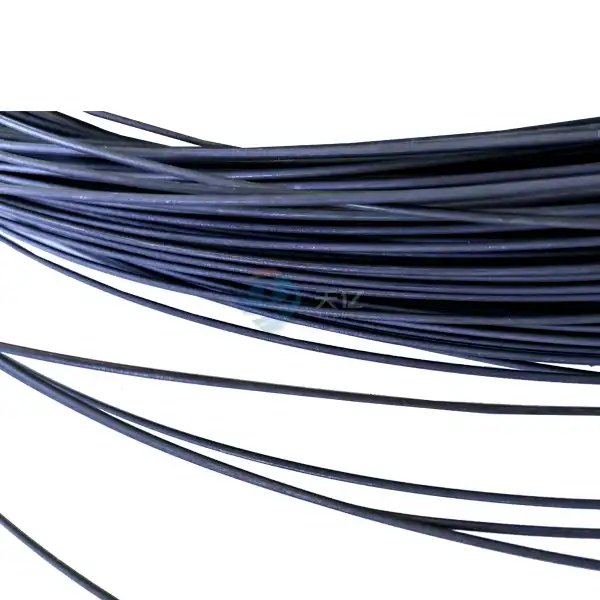

Wire Drawing

The raw material is processed through a wire drawing machine, which reduces the diameter of the metal into thin wires. This process ensures uniform thickness and enhances the mechanical properties of the wire, resulting in a product that meets specific application requirements.

Surface Preparation

The drawn wire undergoes thorough cleaning to remove any oxides, oils, or contaminants. This is often achieved through chemical cleaning, acid pickling, or abrasive blasting, ensuring a clean surface for optimal adhesion of any coatings.

Coating Application

If required, a protective coating, such as mixed metal oxides (MMO) or other specialized coatings, is applied to the wire anode. This process enhances the electrochemical properties and increases the wire’s resistance to corrosion and wear, extending its lifespan in service.

Quality Control Testing

Wire anodes undergo rigorous quality control assessments, which may include tests for tensile strength, elongation, coating thickness, and electrical conductivity. These tests ensure that each anode meets the necessary performance and safety standards.

Cutting and Customization

The wire anodes are cut to desired lengths based on customer specifications. Customization can also include forming the wire into specific shapes or configurations, depending on the application needs.

Final Inspection

Each finished wire anode is subjected to a final inspection to verify dimensions, coating quality, and overall integrity. This ensures that the products are ready for reliable performance in their intended applications.

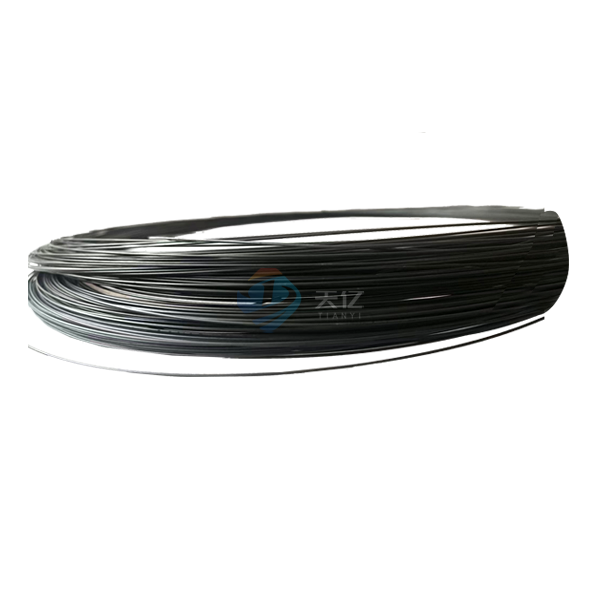

Packaging and Documentation

The completed wire anodes are carefully packaged to prevent damage during transportation. Accompanying documentation typically includes installation instructions, maintenance tips, and warranty information, providing customers with essential information for proper usage and care.

Quality is paramount at Shaanxi Tianyi. Our inspection process includes:

- Raw Material Testing: Ensuring all incoming materials meet stringent quality standards.

- In-Process Inspections: Continuous checks throughout production to maintain consistency.

- Final Product Testing: Each product undergoes thorough testing to ensure it meets performance specifications.

Packaging Method

Our products are packaged with care to prevent damage during transit. We use:

- Custom Packaging: Tailored solutions that protect the product while minimizing waste.

- Labeling: Clear labeling for easy identification and handling.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, allowing you to customize wire anodes to fit your specific requirements. Whether it's unique sizes, coatings, or packaging, we work closely with our clients to deliver tailored solutions.

FAQ

1. What industries use these?

These are commonly used in water treatment, electroplating, cathodic protection, and industrial electrochemical applications.

2. Can I customize the size of the it?

Yes, we offer customizable sizes to meet your specific application needs.

3. What is the expected lifespan of your product?

The lifespan depends on the application, but our products are designed for durability and long service life.

4. Do you provide after-sales support?

Yes, we offer comprehensive after-sales support, including technical assistance and product replacements if needed.

5. How can I place an order?

You can contact us directly at info@di-nol.com for inquiries or to place an order.

Contact Us

For more information on our wire anodes and how they can benefit your business, please contact us at info@di-nol.com. At Shaanxi Tianyi, we are committed to providing high-quality products and exceptional customer service. Let us be your trusted partner in electrochemical technologies!