MMO Wire Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

MMO Wire Anode Product Introduction

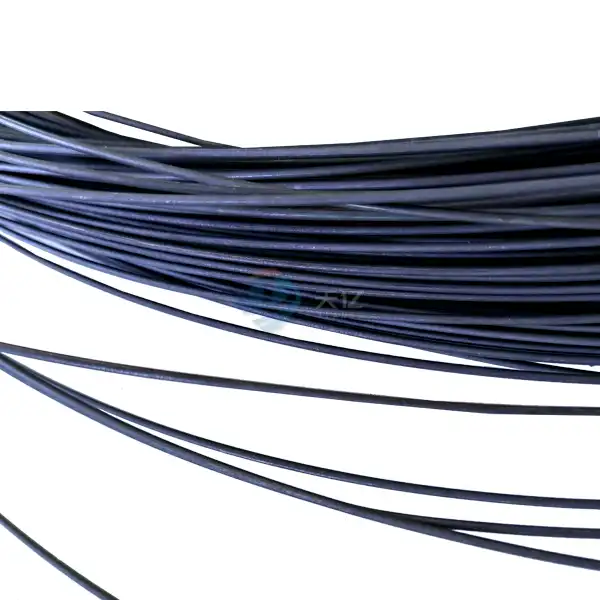

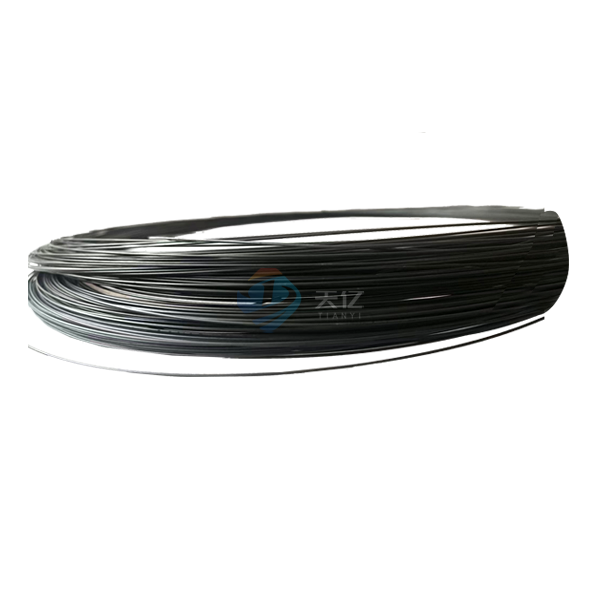

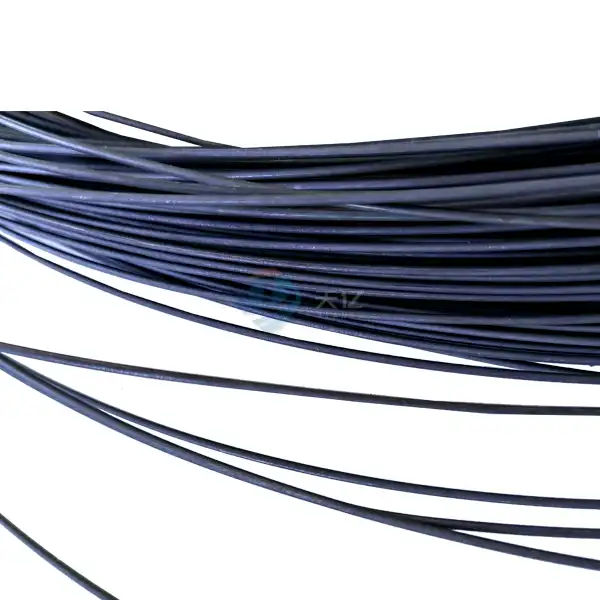

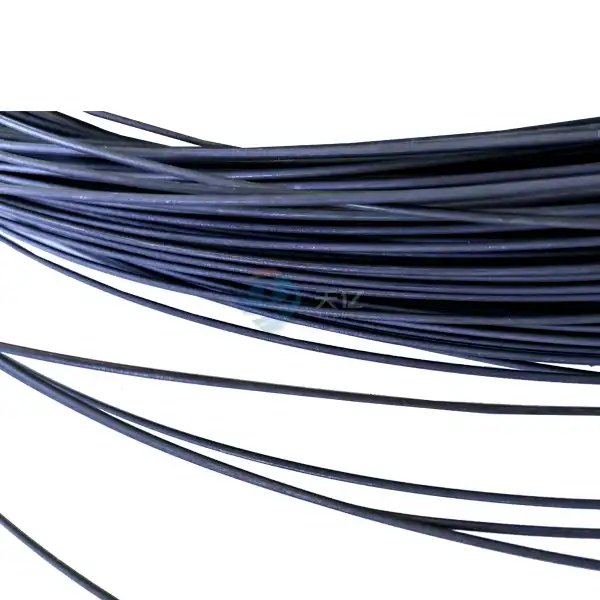

Welcome to our product page for MMO Wire Anodes—a cutting-edge solution designed to meet the demanding needs of various industries. Our products are specially crafted from high-performance titanium and coated with advanced materials to enhance durability and efficiency. These anodes are essential for applications in electroplating, cathodic protection, and other electrochemical processes, making them a vital component in achieving optimal results.

Product Specifications

productparameter | ||

Electrolytes | Withstand current density (A/m2) | Life expectancy (years) |

Carbon filler | 50 | 20 |

Calcined coke | 100 | 20 |

freshwater | 100 | 20 |

silt | 100 -300 | 20 |

seawater | 600 | 20 |

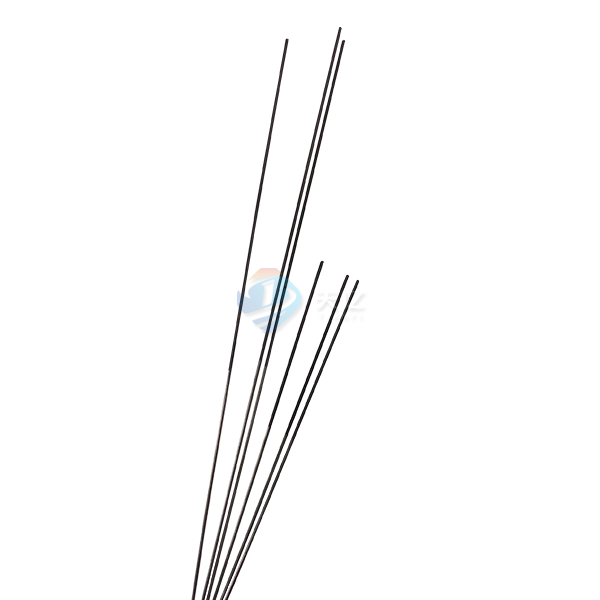

Diameter(mm) length can be customized | Coating Type | Output current (mA/m) | Design life (years) |

1.5 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 328 | 20-50 |

2 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 500 | 20-50 |

3 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 656 | 20-50 |

|  |  |

|  |  |

Product Composition and Design

Our MMO Wire Anodes are designed using a unique combination of titanium and mixed metal oxide coatings, ensuring optimal performance in corrosive environments. The titanium core provides excellent strength and corrosion resistance, while the MMO coating enhances the anode's efficiency and longevity. This innovative design allows for a significant reduction in anode consumption, providing a cost-effective solution for our clients.

Product Advantages

- High Durability: Our anodes are built to withstand harsh conditions, ensuring a longer service life.

- Excellent Corrosion Resistance: The advanced coating technology protects against corrosion, extending the anode’s usability.

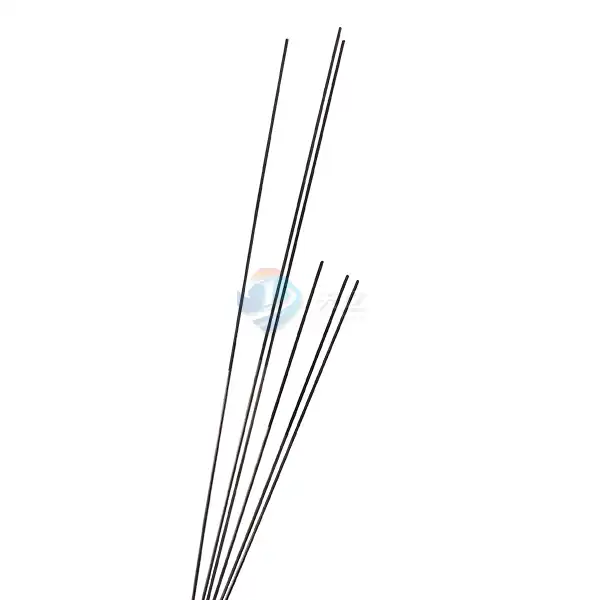

- Customizable Sizes: We offer flexible dimensions to meet specific application requirements.

- Environmentally Friendly: Our products contribute to eco-friendly practices in various industries.

Technical Features

- High Current Efficiency: Designed for efficient electron transfer, ensuring optimal performance during electrochemical reactions.

- Low Operating Costs: With enhanced durability, these anodes reduce the need for frequent replacements.

- Versatile Applications: Suitable for a range of industries, including water treatment, electroplating, and mining.

Product Application

MMO Wire Anodes find their use in multiple industries, such as:

1. Used alone as an auxiliary anode for cathodic protection, or as an MMO electrocatalytic electrode for a cylindrical anode or a flexible anode;

2. Can be used for cathodic protection of continuous horizontal beds, discontinuous vertical surfaces, storage tank equipment, cable protection, water boiling containers, etc.;

3. Can also be used as an auxiliary anode for industrial electroplating and an electrocatalytic oxidation electrode for electrochemical water treatment.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

We adhere to strict production protocols to ensure the highest quality:

Material Selection

High-purity titanium wire is chosen as the substrate for the MMO (Mixed Metal Oxide) wire anode due to its excellent corrosion resistance and mechanical strength. This base material is crucial for ensuring long-term durability in electrolytic processes.

Wire Drawing

The selected titanium is drawn into fine wire using specialized wire drawing machines. This process reduces the diameter to precise specifications, creating a uniform wire that meets the required electrical and mechanical properties for optimal performance.

Surface Preparation

The wire undergoes rigorous cleaning and surface preparation. This may involve chemical cleaning or electro-polishing to remove impurities, oxides, and contaminants, ensuring a clean surface that promotes better adhesion of the MMO coating.

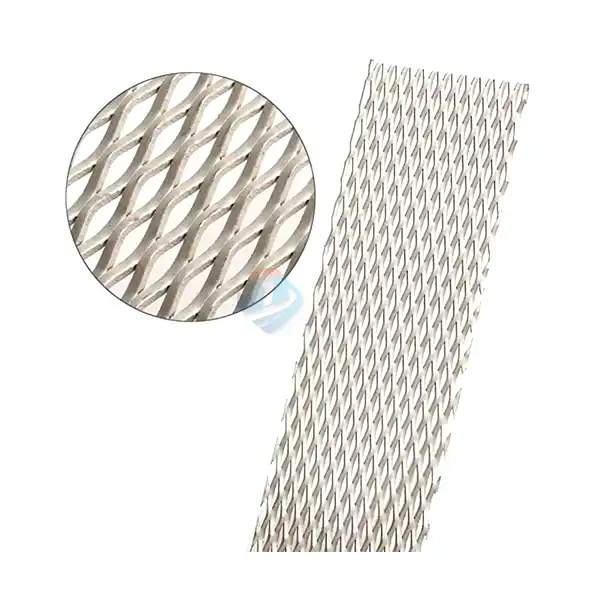

MMO Coating Application

The prepared titanium wire is coated with a layer of mixed metal oxides. This is typically done using a thermal spray process or chemical vapor deposition. The MMO coating is crucial for enhancing the electrochemical activity of the anode, significantly improving its performance in electrolytic applications.

Curing Process

After coating, the wire anode is subjected to a curing process at controlled temperatures. This step ensures that the MMO coating adheres properly to the titanium substrate, enhancing its stability and effectiveness in service.

Quality Control Testing

Each batch of MMO wire anodes is subjected to stringent quality control measures. Testing includes evaluating the thickness of the coating, checking for uniformity, measuring electrical conductivity, and conducting tensile strength assessments to ensure the anodes meet industry standards.

Cutting and Customization

The MMO wire anodes are cut to specific lengths as per customer requirements. Customization options may include bending or shaping the wire to fit various applications, ensuring versatility in installation.

Final Inspection

A final inspection is conducted on each wire anode to verify its dimensions, coating quality, and overall integrity. This step is crucial for ensuring that each product is ready for reliable performance in electrolytic processes.

Packaging and Documentation

The finished MMO wire anodes are packaged securely to prevent damage during transit. Documentation accompanying the product typically includes installation instructions, maintenance guidelines, and warranty information, ensuring customers have the necessary information for proper use.

Quality Inspection

Quality is our top priority. Each batch of MMO Wire Anodes undergoes rigorous testing, including:

- Corrosion Resistance Tests: To ensure longevity and performance.

- Adhesion Tests: To confirm the durability of the coating.

- Dimensional Checks: To verify that all specifications are met.

Packaging Method

Our packaging solutions are designed to protect the integrity of the anodes during transport:

- Custom Packaging: Tailored to fit each order, ensuring safe delivery.

- Moisture-Proof Materials: To prevent corrosion during shipping.

- Eco-Friendly Options: Committed to sustainable practices in our packaging.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, allowing for:

- Custom Coating Solutions: Tailored to your specific needs.

- Branding Options: Personalize products to fit your brand identity.

- Flexible Production Runs: Small or large quantities, we can accommodate your requirements.

FAQ

Q: What industries benefit from products?

A: Industries such as water treatment, mining, electroplating, and disinfection rely on our anodes for optimal performance.

Q: How long do these last?

A: With proper use, our anodes can last over 10 years, significantly reducing replacement frequency.

Q: Can I customize the size of the anodes?

A: Yes, we offer customizable sizes to meet specific application requirements.

Q: Are your products environmentally friendly?

A: Absolutely! We focus on eco-friendly technologies and sustainable practices in our production process.

Q: How can I place an order?

A: You can contact us directly for inquiries and orders.

Contact Us

For more information about our MMO Wire Anodes or to place an order, please reach out to us at info@di-nol.com. Our dedicated team is here to assist you with any questions and ensure you find the right solution for your needs.

_1731229210902.webp)