Titanium Wire Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

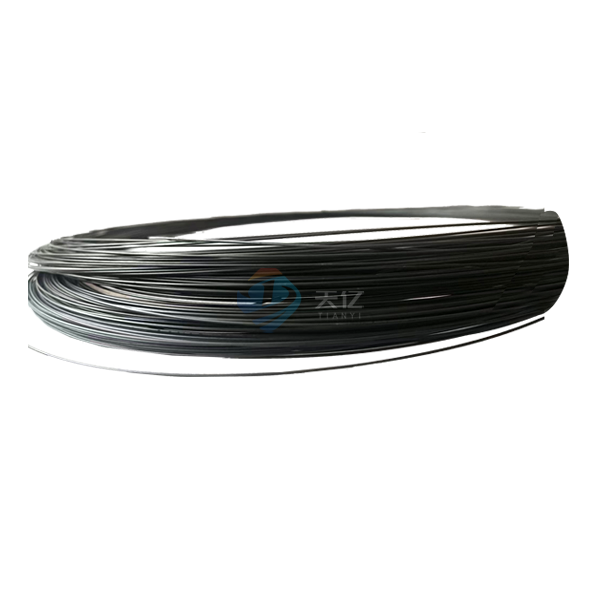

Titanium Wire Anode Introduction

At TianYI, we specialize in high-quality titanium wire anode designed for superior performance in a variety of industrial applications. Our products making them the preferred choice for businesses seeking reliable solutions in water treatment, chemical production, maritime protection, oil and gas refining, and power generation.

Product Specifications

productparameter | ||

Electrolytes | Withstand current density (A/m2) | Life expectancy (years) |

Carbon filler | 50 | 20 |

Calcined coke | 100 | 20 |

freshwater | 100 | 20 |

silt | 100 -300 | 20 |

seawater | 600 | 20 |

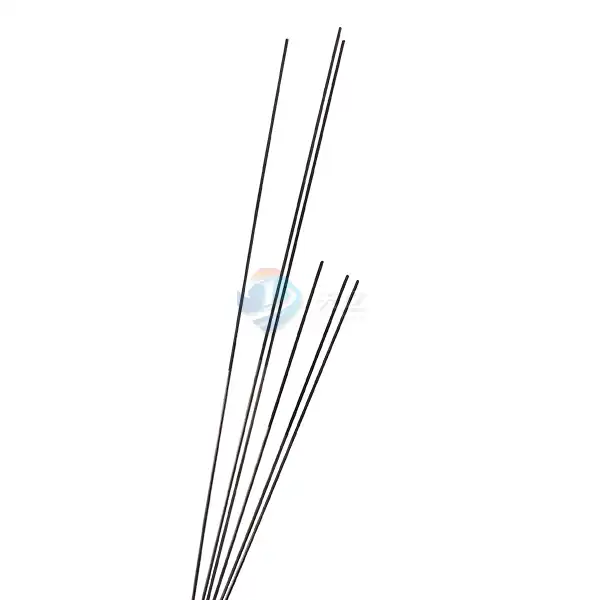

Diameter(mm) length can be customized | Coating Type | Output current (mA/m) | Design life (years) |

1.5 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 328 | 20-50 |

2 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 500 | 20-50 |

3 | Ruthenium-iridium, iridium-tantalum, platinum-plated | 656 | 20-50 |

|  |  |

|  |  |

Product Composition and Design

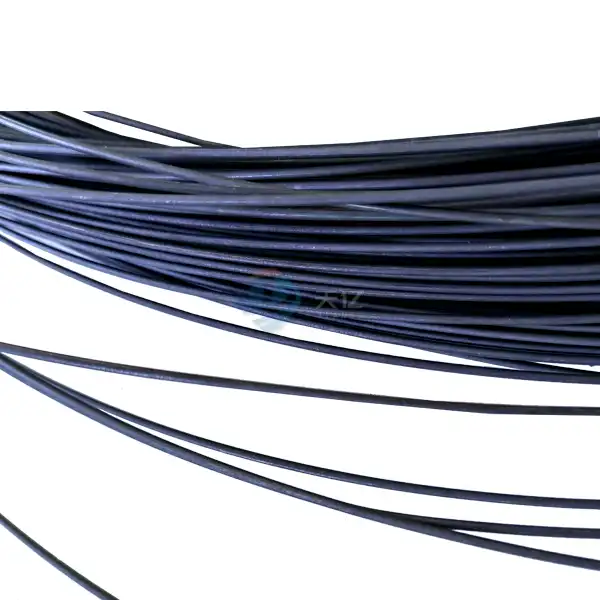

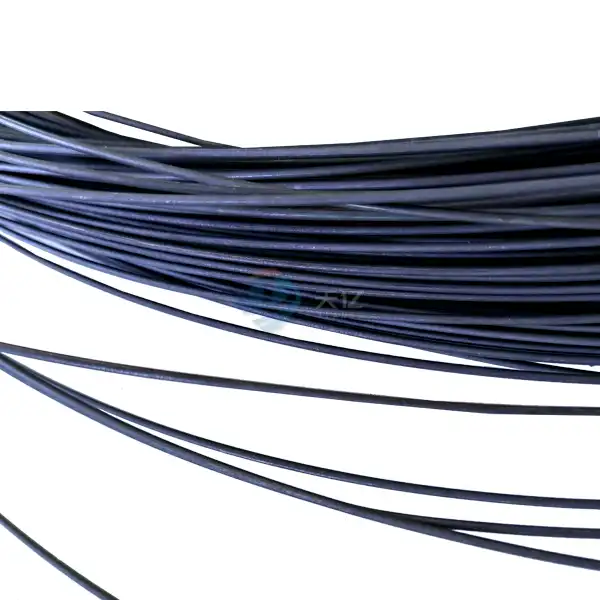

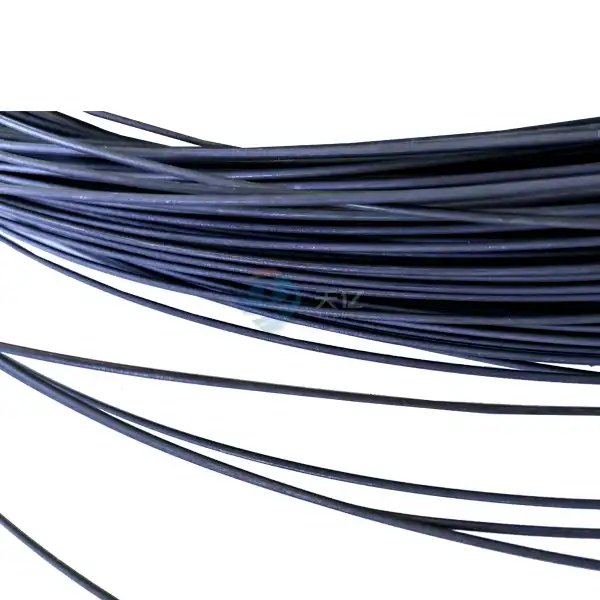

Our Titanium Wire Anodes are crafted from high-purity titanium alloys, providing exceptional corrosion resistance and mechanical strength. The anodes feature an MMO coating, which enhances their electrochemical properties and extends their lifespan. The design is flexible, allowing for various configurations tailored to your specific needs.

Product Advantages

- Corrosion Resistance: Titanium's natural resistance to corrosion ensures longevity, even in harsh environments.

- High Performance: The MMO coating improves current efficiency and enhances electrochemical reactions.

- Customizable: We offer tailored sizes and specifications to meet unique project requirements.

- Lightweight: Titanium's low density reduces the overall weight of your systems, making installation easier.

Technical Features

- Superior Electrical Conductivity: Our products deliver consistent performance with minimal resistance.

- Durability: Designed to withstand extreme conditions, ensuring long-term reliability in various applications.

- Eco-Friendly: Titanium is recyclable and contributes to sustainable practices in electrochemical applications.

Product Application

Titanium Wire Anodes are versatile and used in numerous applications, including:

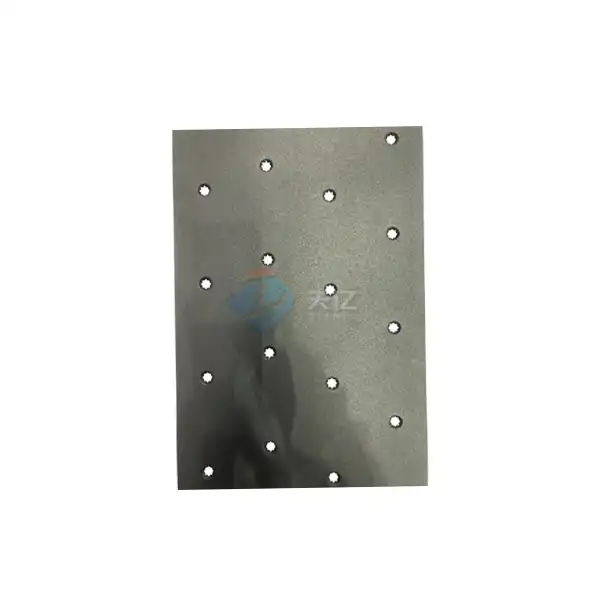

1. Used alone as an auxiliary anode for cathodic protection, or as an MMO electrocatalytic electrode for a cylindrical anode or a flexible anode;

2. Can be used for cathodic protection of continuous horizontal beds, discontinuous vertical surfaces, storage tank equipment, cable protection, water boiling containers, etc.;

3. Can also be used as an auxiliary anode for industrial electroplating and an electrocatalytic oxidation electrode for electrochemical water treatment.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our titanium wire anode production process adheres to strict quality standards to deliver top-notch products:

Material Selection: Only the finest grade titanium is used.

Wire Drawing: Precision drawing to achieve accurate diameters.

Coating Application: Advanced techniques ensure uniform and effective coatings.

Testing & Quality Assurance: Rigorous testing for durability and performance.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Each batch of Titanium Wire Anodes undergoes rigorous testing, including:

- Dimensional inspections

- Coating thickness assessments

- Electrochemical performance tests

Packaging Method

Our packaging solutions are designed to ensure safe transit and delivery. Each product is packaged securely, using protective materials to prevent damage during transportation. We also offer custom packaging options based on client needs.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services that enable you to customize products according to your exact specifications. Our dedicated team collaborates closely with you throughout the process, ensuring that your unique requirements are fully understood and implemented. From design to production, we prioritize quality and performance, utilizing advanced manufacturing techniques to meet the highest standards.

FAQ

Q: What is the typical lifespan of a product?

A: With proper maintenance and usage, our titanium anodes can last several years, significantly reducing replacement frequency.

Q: Can I get customized sizes?

A: Yes, we offer fully customizable lengths and diameters to meet your project requirements.

Q: Are these anodes suitable for seawater applications?

A: Absolutely! Our titanium anodes are designed to perform well in both fresh and seawater environments.

Q: What is the minimum order quantity?

A: We accommodate various order sizes, with no minimum order requirement for standard products.

Contact Us

For more information about our Titanium Wire Anodes or to discuss your specific needs, please reach out to us at info@di-nol.com. Our team is ready to assist you in finding the perfect solution for your electrochemical applications!

YOU MAY LIKE

_1731641984159.webp) VIEW MOREDiaphragmless electrolyzer

VIEW MOREDiaphragmless electrolyzer VIEW MORERuthenium-iridium coated titanium anode

VIEW MORERuthenium-iridium coated titanium anode VIEW MOREMMO-Ti Wire Anode

VIEW MOREMMO-Ti Wire Anode VIEW MOREMMO Wire Anode

VIEW MOREMMO Wire Anode VIEW MOREWire Anode

VIEW MOREWire Anode VIEW MOREIr-Ta coated titanium oxide anode

VIEW MOREIr-Ta coated titanium oxide anode VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating

VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating VIEW MORETitanium Anode For Sodium Hypochlorite Generator

VIEW MORETitanium Anode For Sodium Hypochlorite Generator