Titanium Anode For Sodium Hypochlorite Generator

Higher current efficiency

Longer service life

No water pollution

Wide application range

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. Our Titanium Anode for Sodium Hypochlorite Generator is engineered for superior performance in the production of sodium hypochlorite through electrolysis. This anode plays a crucial role in ensuring efficient and consistent chlorine generation for various applications, including water treatment and disinfection.

Product Specifications

|  |  |

|  |  |

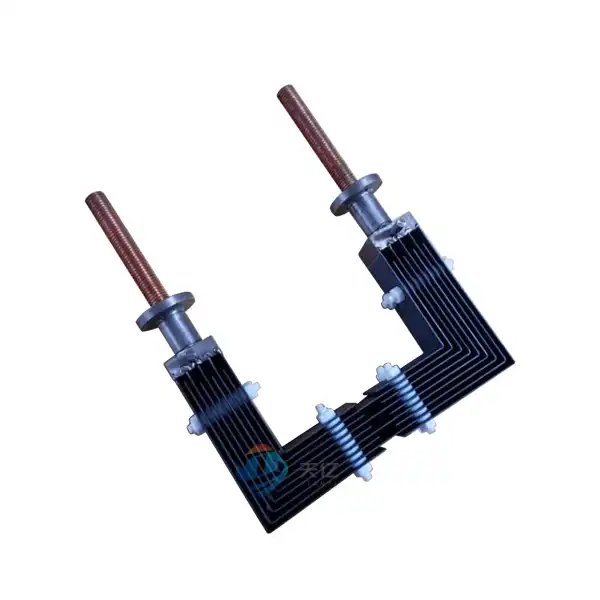

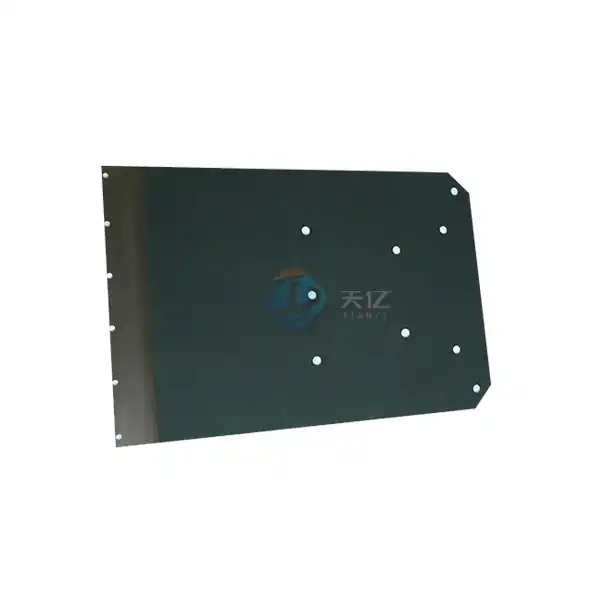

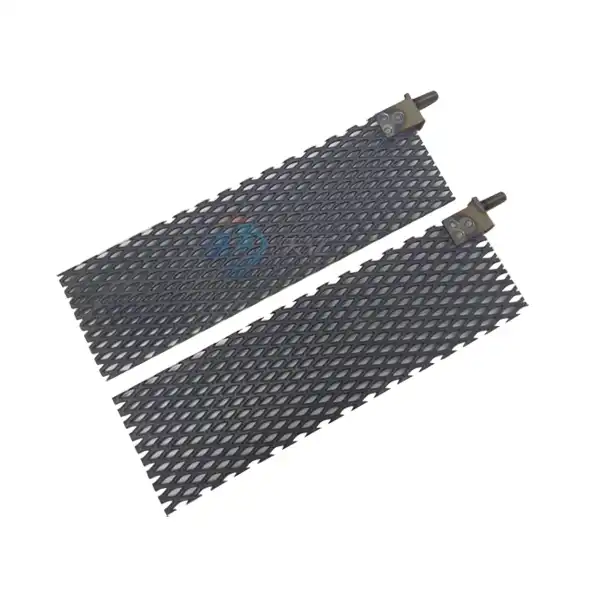

Product Composition and Design

Our titanium anodes are composed of high-grade titanium substrates coated with MMO. This coating enhances the anode's performance, allowing it to withstand high current densities while minimizing corrosion and maximizing longevity. The design is tailored to fit a variety of sodium hypochlorite generator systems, ensuring compatibility and optimal performance.

Product Advantages

- High Efficiency: Our Titanium Anode for Sodium Hypochlorite Generator provide excellent electrochemical performance, significantly enhancing the efficiency of sodium hypochlorite generation.

- Corrosion Resistance: The advanced MMO coating offers exceptional resistance to corrosion, extending the lifespan of the anode.

- Customizable Options: We understand that each application may have unique requirements; therefore, we offer customizable sizes and specifications.

Technical Features

- Stability: Maintains consistent performance under varying operational conditions.

- Durability: Designed for long-term use with minimal degradation over time.

- Eco-Friendly: Contributes to environmentally friendly practices by facilitating effective disinfection and water treatment.

Product Application

The Titanium Anode for Sodium Hypochlorite Generator is ideal for:

Chlor-alkali industrial water treatment, chlorine production, sodium hypochlorite electrolysis production,wastewater treatment and swimming pool cleaning.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

Begin with high-purity titanium, typically Grade 1 or Grade 2, known for its excellent corrosion resistance and mechanical strength. This ensures optimal performance in harsh electrolytic environments, especially in sodium hypochlorite generation.

Design and Specifications

Define the dimensions and shape of the titanium anode, considering factors like surface area and thickness to enhance the efficiency of the electrochemical reaction involved in sodium hypochlorite production.

Powder Preparation (if applicable)

If using titanium powder, prepare it through methods such as atomization or grinding. The titanium powder should be of high purity and uniform particle size for effective processing.

Anode Formation

Form the titanium anode using techniques like extrusion, pressing, or machining. This involves shaping the titanium into the desired configuration, ensuring proper density and structural integrity.

Surface Preparation

Perform surface treatments, such as sandblasting or acid etching, to clean and prepare the titanium surface. This enhances the adhesion of subsequent coatings and increases the active surface area.

Coating Application

Apply a mixed metal oxide (MMO) coating or a noble metal coating, such as ruthenium or iridium, using electroplating or thermal spraying methods. This coating improves the electrochemical properties and longevity of the anode during operation.

Curing Process

Cure the coated titanium anodes at specified temperatures to ensure proper bonding of the coating. This step is crucial for enhancing the durability and performance of the anodes in sodium hypochlorite generation.

Quality Control Testing

Conduct thorough quality control inspections, including dimensional checks, surface integrity assessments, and evaluation of the coating quality. Ensure that the anodes meet established industry standards.

Electrochemical Testing

Perform electrochemical testing to assess the efficiency of the titanium anodes in sodium hypochlorite production. Test their performance in simulated operational conditions to ensure reliability and effectiveness.

Final Finishing

Apply any necessary finishing touches, such as polishing or additional surface treatments, to enhance the appearance and performance of the titanium anodes.

Packaging and Labeling

Package the finished titanium anodes in protective materials to prevent damage during transport. Clearly label the packaging with product specifications, usage instructions, and safety information.

Documentation and Certification

Provide comprehensive documentation that includes technical specifications, installation guidelines, and maintenance instructions. Include any relevant certifications to assure customers of the product's quality and safety.

By following this structured production process, manufacturers can ensure that titanium anodes for sodium hypochlorite generators are produced to high standards, optimizing their performance in water disinfection applications.

Quality Inspection

Quality is our priority. Every batch of Titanium Anode for Sodium Hypochlorite Generator undergoes rigorous quality checks, including:

- Raw material inspection

- Coating thickness measurement

- Performance testing under simulated operational conditions

Packaging Method

Our packaging solutions are designed to protect the anodes during transit. We utilize:

- Custom-sized cartons

- Anti-static wrapping

- Shock-absorbent materials

This ensures that your products arrive safely and in perfect condition.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM/ODM services that empower clients to fully customize their orders according to their specific requirements. Whether you need tailored dimensions, unique coating compositions, or specialized formulations, our experienced team is dedicated to providing expert assistance at every stage of the process. From initial consultation to final production, we ensure that your vision is brought to life with precision and quality. With our commitment to flexibility and innovation, we strive to meet your unique needs and help you achieve your business goals.

FAQ

Q1: How long does the titanium anode last?

A1: Our Titanium Anode for Sodium Hypochlorite Generator can last up to 10,000 hours, depending on operational conditions.

Q2: Can I customize the size of the anode?

A2: Yes, we offer customizable sizes to fit various generator models.

Q3: What is the typical current density for these anodes?

A3: Our anodes can operate effectively at current densities up to 1000 A/m².

Contact Us

For more information or to discuss your specific needs, please reach out to us at info@di-nol.com. Our dedicated team is here to help you find the best solutions for your electrochemical applications.

YOU MAY LIKE

VIEW MORELead dioxide anode

VIEW MORELead dioxide anode_1731380858183.webp) VIEW MORETitanium Anode For Slightly Acidic Electrolyzed Water

VIEW MORETitanium Anode For Slightly Acidic Electrolyzed Water VIEW MORETitanium Anode For Electrolyzed Oxidizing Water

VIEW MORETitanium Anode For Electrolyzed Oxidizing Water VIEW MOREtitanium electrodes for salt water electrolysis

VIEW MOREtitanium electrodes for salt water electrolysis VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil

VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil VIEW MORETitanium Anode Tablets For Swimming Pool Disinfection

VIEW MORETitanium Anode Tablets For Swimming Pool Disinfection VIEW MORETitanium Anode Mesh For Swimming Pool Disinfection

VIEW MORETitanium Anode Mesh For Swimming Pool Disinfection