Titanium Anode Mesh For Swimming Pool Disinfection

Higher current efficiency

Longer service life

No water pollution

Wide application range

- Product Description

Product Introduction

Welcome to the future of swimming pool maintenance with our Titanium Anode Mesh for Swimming Pool Disinfection. This innovative product is designed to enhance your swimming pool’s water quality by providing effective disinfection while ensuring longevity and efficiency. As part of our commitment to sustainable solutions, this titanium anode mesh not only meets the highest industry standards but also contributes to a cleaner environment.

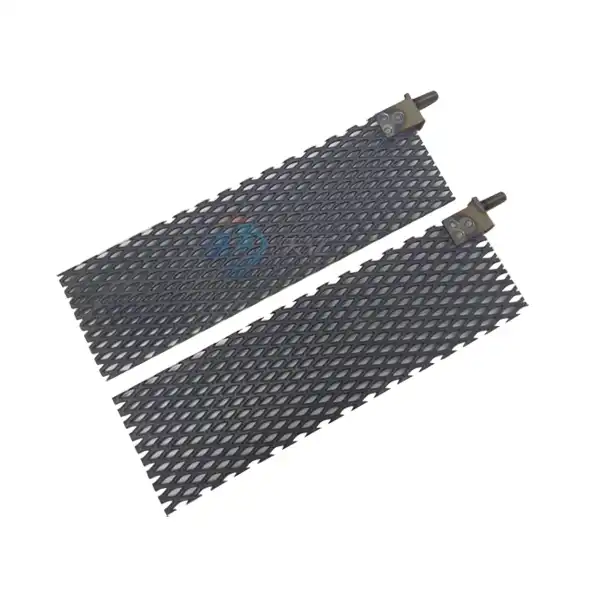

Product Show

Product Composition and Design

Our Titanium Anode Mesh for Swimming Pool Disinfectio is composed of high-quality titanium alloy, featuring a Mixed Metal Oxide (MMO) coating that enhances its durability and corrosion resistance. The mesh design allows for optimal water flow, maximizing the electrochemical reactions that disinfect pool water effectively. This unique composition ensures that our product performs exceptionally well in various water conditions, providing peace of mind for pool owners.

Product Advantages

- Long Lifespan: With a service life of up to 10 years, this titanium anode mesh reduces the frequency of replacements, saving you time and money.

- Eco-Friendly: Made from sustainable materials, our product contributes to the reduction of harmful chemicals in your pool.

- Efficient Disinfection: Effectively eliminates bacteria and algae, ensuring a safe and clean swimming environment.

- Low Maintenance: Designed for easy installation and minimal upkeep, allowing you to enjoy your pool without hassle.

Technical Features

- High Electrolytic Efficiency: Our titanium anode mesh operates efficiently within a voltage range of 6-12V, optimizing disinfection.

- Customizable Sizes: Available in various sizes to fit different pool configurations.

- Corrosion Resistance: The MMO coating provides superior protection against corrosion, ensuring longevity.

Product Application

Chlor-alkali industrial water treatment, chlorine production, sodium hypochlorite electrolysis production,wastewater treatment and swimming pool cleaning.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

Choose high-quality titanium, typically Grade 1 or Grade 2, known for its corrosion resistance and durability in chlorinated environments. This ensures longevity and effective performance in swimming pool disinfection.

Mesh Design and Specifications

Develop specific designs for the anode mesh, including mesh size, wire thickness, and overall dimensions. The design should maximize surface area for effective electrochemical reactions while ensuring proper water flow.

Cutting and Shaping

Use precision cutting techniques to form the titanium sheets into the desired mesh shape. Employ methods such as laser cutting or wire EDM (Electrical Discharge Machining) to achieve accurate and consistent results.

Welding and Assembly

Weld or assemble multiple titanium mesh layers to create the final anode structure. This enhances structural integrity and allows for greater surface area, improving the anode's effectiveness in disinfection.

Surface Treatment

Perform surface preparation by cleaning and polishing the titanium mesh. This may involve degreasing, abrasive blasting, or acid etching to enhance the surface for coating adhesion and improve electrochemical performance.

Coating Application

Apply a specialized coating, such as a mixed metal oxide (MMO) or noble metal layer, to the titanium mesh. This coating improves the anode's electrochemical properties and enhances its efficiency in generating disinfectant solutions.

Curing Process

Cure the coated anode mesh at controlled temperatures to promote optimal bonding of the coating to the titanium substrate. This ensures durability and effectiveness during disinfection processes.

Quality Control Testing

Conduct rigorous quality control inspections to assess the anode mesh for defects, dimensional accuracy, and coating integrity. Test for corrosion resistance and performance to ensure compliance with industry standards.

Electrochemical Testing

Perform electrochemical evaluations in simulated swimming pool conditions to measure the anode's performance. Assess parameters such as current efficiency, stability, and chlorine generation capability.

Final Assembly and Integration

Prepare the titanium anode mesh for installation in swimming pool disinfection systems. Ensure compatibility with existing pool equipment and include necessary mounting hardware or connections.

Packaging and Documentation

Package the finished anode mesh securely to prevent damage during shipping. Include detailed documentation that outlines technical specifications, installation guidelines, and maintenance instructions for end-users.

By adhering to this meticulous production process, manufacturers can ensure that titanium anode meshes for swimming pool disinfection are crafted to meet high performance and durability standards, effectively maintaining water quality and safety.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Each titanium anode mesh undergoes a series of inspections, from raw material sourcing to final product testing. Our quality control team ensures that every product exceeds industry standards, providing you with confidence in your purchase.

Packaging Method

To ensure the integrity of our Titanium Anode Mesh for Swimming Pool Disinfectio during transit, we employ custom packaging solutions that are both protective and cost-effective. Each product is securely packaged to prevent damage, with eco-friendly materials that align with our commitment to sustainability.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services tailored to meet your specific requirements. Whether you need customized sizes, coatings, or branding, our team is dedicated to delivering solutions that fit your needs perfectly.

FAQ

Q: How long does the titanium anode mesh last?

A: Our titanium anode mesh can last up to 10 years with proper maintenance.

Q: Is the product easy to install?

A: Yes, the titanium anode mesh is designed for straightforward installation, allowing you to set it up quickly.

Q: Can I use it in any type of swimming pool?

A: Yes, it is suitable for various pool types, including in-ground and above-ground pools.

Q: What maintenance is required?

A: Minimal maintenance is required; regular inspections and cleaning are recommended to ensure optimal performance.

Contact Us

For more information about our Titanium Anode Mesh for Swimming Pool Disinfection or to place an order, please contact us at info@di-nol.com. Our team is ready to assist you with any inquiries and provide the support you need for your swimming pool solutions.

YOU MAY LIKE

VIEW MOREPlatinum-titanium anode

VIEW MOREPlatinum-titanium anode_1731380858183.webp) VIEW MORETitanium Anode For Slightly Acidic Electrolyzed Water

VIEW MORETitanium Anode For Slightly Acidic Electrolyzed Water VIEW MORETitanium Anode For Steel Plate Galvanizing

VIEW MORETitanium Anode For Steel Plate Galvanizing VIEW MORETitanium Anode For Electrolyzed Oxidizing Water

VIEW MORETitanium Anode For Electrolyzed Oxidizing Water VIEW MORERuthenium-iridium mixed oxide coated titanium anode

VIEW MORERuthenium-iridium mixed oxide coated titanium anode VIEW MORETitanium Anode For Sodium Hypochlorite Generator

VIEW MORETitanium Anode For Sodium Hypochlorite Generator VIEW MORETitanium Anode Tablets For Swimming Pool Disinfection

VIEW MORETitanium Anode Tablets For Swimming Pool Disinfection