Titanium Anode For Steel Plate Galvanizing

Uniform current distribution deposits the plating material evenly and consistently

Extremely efficient plating anode accelerates the deposition of the plating material

Excellent thermal performance

High durability

- Product Description

Product Introduction

At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we are proud to present our Titanium Anode for Steel Plate Galvanizing, a cutting-edge solution designed to enhance the efficiency and effectiveness of galvanizing processes. Our titanium anodes are crafted using advanced electrochemical technologies, ensuring optimal performance and longevity. These anodes play a vital role in protecting steel surfaces from corrosion while providing a smooth and uniform zinc coating during the galvanization process.

Product Specifications

System Category | Coating Type | Current density (A/m2) | Dimensions |

Micro-etching liquid | Iridium Tantalum Mixed Oxide | 200-400 | All can be customized |

Alkaline etching solution | Iridium Tantalum/Lead Dioxide | 100-300 | All can be customized |

Acid etching solution | Ruthenium-iridium mixed oxide | 300-500 | All can be customized |

|  |

|  |

Product Composition and Design

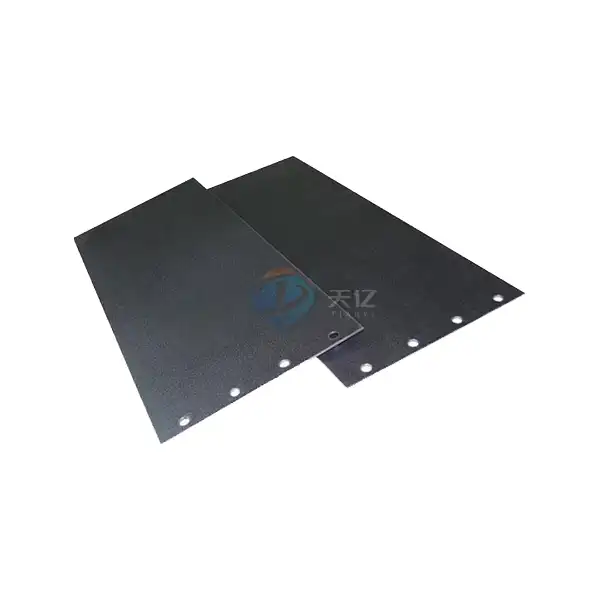

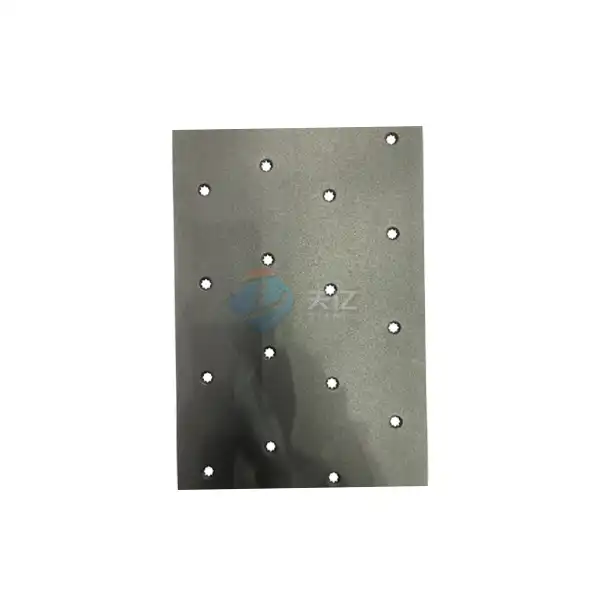

Our Titanium Anode for Steel Plate Galvanizing feature a robust design that incorporates MMO coatings for enhanced electrochemical performance. The use of high-quality titanium ensures excellent corrosion resistance and durability, making them suitable for long-term use in galvanizing applications. The customizable thickness and dimensions allow for tailored solutions that meet specific operational needs.

Product Advantages

- Exceptional Durability: Our titanium anodes are resistant to wear and corrosion, ensuring a long service life even in harsh environments.

- High Efficiency: The MMO coating maximizes current efficiency, leading to faster galvanizing processes and reduced energy consumption.

- Custom Solutions: We offer fully customizable anodes designed to meet your specific galvanizing requirements, ensuring compatibility with your systems.

Technical Features

- Enhanced Current Distribution: Our anodes provide uniform current distribution, ensuring consistent coating thickness across the steel surface.

- Eco-Friendly: Our manufacturing processes prioritize sustainability, contributing to environmental protection efforts.

- Easy Installation: Designed for seamless integration into existing galvanizing systems, our anodes can be easily installed and maintained.

Product Application

Our Titanium Anode for Steel Plate Galvanizing is ideal for:

Electronics Industry: Precision is essential in electronics, and electroplating anodes help achieve flawless coatings on delicate components, enhancing their durability and performance.

Automotive Industry: Electroplating anodes are key to producing durable, corrosion-resistant coatings and polished chrome finishes, contributing to both the functionality and aesthetics of automotive parts.

Aerospace Industry: Aerospace applications require components to withstand extreme conditions. Electroplating anodes are crucial for producing parts that meet the strict standards for quality and durability in this sector.

Jewelry and Decorative Arts: Electroplating anodes enable the creation of beautiful, long-lasting finishes on jewelry and decorative items, ensuring their quality and visual appeal.

Medical Devices: For medical devices, electroplating provides corrosion-resistant and hygienic surfaces, ensuring the safety, reliability, and longevity of critical medical instruments.

Oil and Gas Industry: Electroplating anodes are essential for applying protective coatings that enhance the corrosion resistance and longevity of equipment used in challenging oil and gas environments.

Renewable Energy: In renewable energy systems, electroplated components benefit from enhanced durability and efficiency, contributing to the reliability of sustainable energy solutions.

Agriculture: Electroplating adds wear and corrosion resistance to components used in agricultural machinery, improving their durability under tough working conditions.

Aviation Industry: Precision coatings achieved with electroplating anodes are essential for manufacturing reliable aircraft components that meet stringent aviation standards.

Textile Industry: Electroplating anodes provide durable coatings for textile machinery parts, boosting their performance and longevity in demanding operational settings.

Telecommunications: In telecommunications, electroplated components enable dependable connections and efficient signal transmission, ensuring network reliability.

General Manufacturing: Electroplating anodes support numerous manufacturing processes by enhancing the quality and lifespan of items, from fasteners to industrial equipment, across various sectors.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

The production process starts with the careful selection of high-purity titanium as the base material. Titanium is preferred for its exceptional corrosion resistance and strength, making it ideal for use in galvanizing applications.

Cutting and Shaping

The titanium is cut into specific shapes and sizes required for the galvanizing process. Precision cutting techniques, such as laser cutting or water jet cutting, are used to ensure that each anode meets the dimensional specifications necessary for effective performance.

Surface Preparation

After cutting, the titanium anodes undergo thorough surface preparation. This involves cleaning the surfaces to remove any contaminants, oils, or oxides, typically using chemical cleaning agents and mechanical abrasion. This step is crucial for ensuring proper adhesion of the coating.

Coating Application

A mixed metal oxide (MMO) coating is applied to the titanium anodes. This coating is essential for improving the anodes’ electrochemical properties, ensuring high efficiency during the galvanizing process. The application may be done using thermal spraying or electrochemical deposition techniques.

Curing and Bonding

Following the coating application, the anodes are subjected to a curing process. This involves heating the anodes to promote a strong bond between the titanium substrate and the MMO layer, enhancing durability and performance under operating conditions.

Quality Assurance

Rigorous quality assurance checks are conducted at various stages of production. Tests for coating thickness, adhesion strength, and electrochemical performance are performed to ensure that the anodes comply with industry standards and specifications.

Dimensional Verification

Each titanium anode undergoes a dimensional verification process to confirm that it meets the required specifications. This step ensures that the anodes fit correctly into the galvanizing equipment, allowing for optimal performance.

Final Surface Treatment

A final surface treatment may be applied to enhance the anodes’ characteristics further. This can include passivation processes to improve corrosion resistance and ensure that the anodes perform effectively in galvanizing applications.

Packaging

Once the anodes have passed all quality checks, they are carefully packaged using protective materials to prevent any damage during transport. Proper packaging is crucial to maintain the integrity of the anodes until they reach the customer.

Documentation

Each shipment includes comprehensive documentation, such as product specifications, handling instructions, and operational guidelines. This information is essential for customers to understand how to properly use and maintain the titanium anodes in galvanizing processes.

Logistics and Delivery

The finished titanium anodes are shipped using reliable logistics services, ensuring timely delivery. Tracking information is often provided to keep customers informed of their orders' status.

Technical Support

Manufacturers typically offer ongoing technical support for customers. This assistance can include guidance on installation, operational best practices, and troubleshooting, helping users maximize the efficiency and lifespan of the titanium anodes during the steel plate galvanizing process.

This comprehensive production process ensures that titanium anodes for steel plate galvanizing are manufactured to high standards of quality and performance, thereby enhancing the galvanizing process in steel production.

Quality Inspection

Every Titanium Anode for Steel Plate Galvanizing is subjected to a comprehensive quality inspection process. This includes:

- Raw Material Testing: Ensuring all materials used meet industry standards.

- Coating Thickness Measurement: Verifying that the MMO coating is applied uniformly and to specification.

- Performance Testing: Assessing the electrochemical performance under various conditions to guarantee reliability.

Packaging Method

We prioritize the safety and integrity of our products during transport. Our packaging methods include:

- Protective Wrapping: Each anode is carefully wrapped to prevent damage during shipping.

- Custom Packaging Solutions: Tailored packaging options to suit specific shipping requirements.

- Eco-Friendly Materials: We use recyclable materials whenever possible to minimize our environmental footprint.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services to customize our titanium anodes according to your specific needs. Our team works closely with clients to ensure that each product is tailored for optimal performance in their galvanizing systems.

FAQ

Q1: What is the lifespan of your titanium anodes?

A1: Our titanium anodes typically have a service life of 10-15 years, depending on operating conditions.

Q2: Can you customize the dimensions of the anodes?

A2: Yes, we provide fully customizable solutions to meet your specific requirements.

Q3: Are your products eco-friendly?

A3: Absolutely! We prioritize sustainable practices in our manufacturing processes.

Q4: How do I order your titanium anodes?

A4: You can contact us directly at info@di-nol.com to discuss your needs and place an order.

Q5: What industries do you serve?

A5: We serve a broad spectrum of industries, including construction, automotive, and electroplating.

Contact Us

For more information about our Titanium Anode for Steel Plate Galvanizing or to discuss your specific requirements, please reach out to us at info@di-nol.com. We look forward to partnering with you in achieving superior galvanizing solutions!

YOU MAY LIKE

VIEW MORERibbon MMO Anodes

VIEW MORERibbon MMO Anodes VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating

VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating VIEW MOREtitanium electrode for electrolysis

VIEW MOREtitanium electrode for electrolysis_1731642084407.webp) VIEW MOREchlorine electrolyzer

VIEW MOREchlorine electrolyzer VIEW MORETitanium Anode For Steel Plate Tinning

VIEW MORETitanium Anode For Steel Plate Tinning VIEW MORETitanium Anode For PCB Electroplating

VIEW MORETitanium Anode For PCB Electroplating VIEW MOREFIP Titanium Anode For Copper Foil Electrolysis

VIEW MOREFIP Titanium Anode For Copper Foil Electrolysis VIEW MORETitanium Anode For Metal Electroplating

VIEW MORETitanium Anode For Metal Electroplating