Welcome to our product page for Ribbon MMO Anodes. At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we specialize in providing high-performance MMO (Mixed Metal Oxide) coated titanium anodes, designed to enhance efficiency in various electrochemical applications. Our products are specifically engineered to deliver superior performance in industrial processes, ensuring longevity and reliability.

Product Specifications

| Coating | Titanium substrate | Specification | Standard length | Design life |

| Iridium-tantalum/ruthenium-iridium mixed oxide | GR1/GR2 | 6.35mm × thickness 0.635mm | 152 meters/roll | 20 to 50 years |

|

| (MMO coating) | 12.7mm × thickness 0.9mm | or 150 meters/roll |

Product Composition and Design

Our Ribbon MMO Anodes are constructed from a high-quality titanium substrate coated with a precise mixture of metal oxides, including ruthenium, iridium, and tantalum. This unique composition ensures optimal performance, even in harsh environments. The ribbon design allows for efficient current distribution, enhancing the anode's effectiveness and operational life.

Product Advantages

Durability: The combination of titanium and MMO coating provides exceptional corrosion resistance, ensuring a long service life.

Efficiency: Designed for low overpotential, our products minimize energy consumption in electrochemical processes.

Customizability: Available in various sizes and thicknesses to meet specific project requirements.

Versatility: Suitable for a wide range of applications, including industrial electroplating and wastewater treatment.

Technical Features

Low Maintenance: The robust design reduces the need for frequent replacements, minimizing operational downtime.

High Performance: Capable of delivering consistent performance under varying conditions, ensuring reliability in demanding applications.

Eco-Friendly: Contributes to sustainable practices in water treatment and metal processing industries.

Product Application

Ribbon MMO Anodes are widely used in several industries, including:

1.Pipeline inner wall corrosion protection

2.Underground storage tanks, ground storage tanks, water storage tanks

3.Condensate tanks, heat exchangers, water treatment equipment

4.Ships, roads, bridges, building steel corrosion protection, etc.

5.Continuous horizontal ground bed, non-continuous horizontal ground bed, shallow buried vertical ground bed.

Be used in a wide range of industries.

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Our Workshop

Product Production Process

Our production process is rooted in advanced manufacturing techniques:

Titanium Ribbon Selection

High-quality titanium ribbons are selected for their strength, flexibility, and corrosion resistance. Each ribbon undergoes an inspection to ensure it meets industry standards for cathodic protection in environments like concrete structures and pipelines.

Surface Treatment

The titanium ribbons are cleaned and treated using processes such as acid etching or sandblasting. This creates a slightly roughened surface, which improves the adherence of the mixed metal oxide (MMO) coating.

MMO Coating Application

A mixed metal oxide coating, typically comprising a blend of iridium, tantalum, or ruthenium oxides, is applied to the prepared ribbons. The coating process may involve dipping or spraying, followed by curing at high temperatures to secure the MMO layer onto the titanium substrate.

Quality Testing of Coating

The coated ribbons undergo rigorous testing to ensure uniform coating thickness and strong adhesion. Conductivity and durability are also tested to confirm the anode’s performance in high-chloride environments like seawater or soil.

Cutting and Customization

Based on project specifications, the ribbon anodes are cut to required lengths. This customization allows for optimal fitting and effectiveness in varied cathodic protection systems, including those with complex geometries.

Connection Assembly

Connection points are reinforced with high-quality, corrosion-resistant materials. These connections are insulated to prevent current loss and maintain performance, particularly in aggressive environments.

Final Inspection and Testing

Each ribbon anode undergoes a final inspection for mechanical strength, coating uniformity, and electrical conductivity. This ensures that every anode meets the standards required for long-term cathodic protection applications.

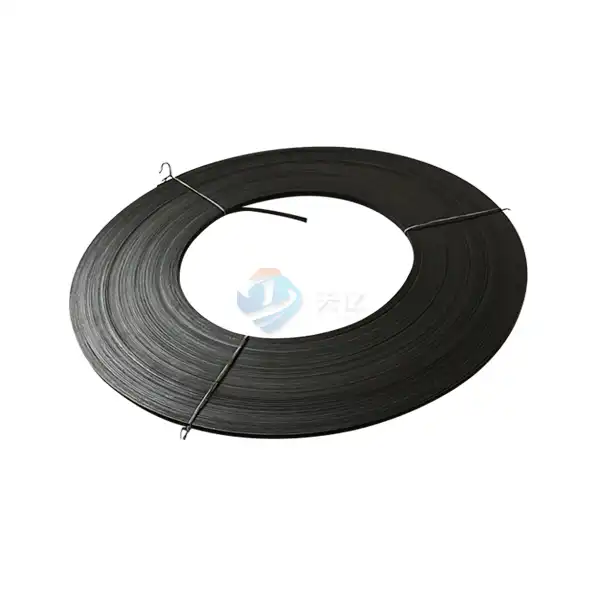

Packaging and Documentation

The ribbon MMO anodes are packaged with care to prevent bending or damage. Documentation, including installation instructions, maintenance guidelines, and technical specifications, is included to assist in the correct and effective installation of the anodes.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Each Ribbon MMO Anode undergoes a comprehensive inspection process, including:

Raw Material Testing: Ensures only the highest quality materials are used.

Coating Thickness Measurement: Verifies adherence to specified coating parameters.

Performance Testing: Each anode is tested under operational conditions to ensure reliability.

Packaging Method

We take great care in packaging our products to ensure they reach you in perfect condition. Our packaging solutions are designed for safety and include moisture-proof materials to protect the anodes during transport.

Our Certificates

Our Team

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services tailored to your unique requirements. Whether you need customized anodes or complete electrochemical systems, we can deliver solutions that meet your specifications.

FAQ

Q1: What are the products used for?

A1: They are primarily used in electroplating, water treatment, and cathodic protection applications.

Q2: Can you customize the size of the anodes?

A2: Yes, we provide fully customizable options to meet your specific needs.

Q3: How long do it last?

A3: Their longevity depends on the operating conditions, but they are designed to provide long service life with minimal maintenance.

Q4: Do you offer technical support?

A4: Absolutely! We provide comprehensive after-sales support, including technical assistance.

Contact Us

For more data about our Ribbon MMO Anode or to examine your particular necessities, kindly connect with us at info@di-nol.com. We anticipate assisting you with tracking down the ideal answer for your electrochemical necessities! Our Strip MMO Anodes are intended for high proficiency and life span, pursuing them an incredible decision for different applications, including cathodic insurance and electrochemical cycles. We comprehend that each task has novel details, and our committed group is here to give master direction to guarantee you select the right item. Whether you really want definite specialized data, help with establishment, or redid choices, we are focused on conveying uncommon help. Feel free to us today to investigate how our answers can improve your tasks!