Titanium Anode For Steel Plate Tinning

Uniform current distribution deposits the plating material evenly and consistently

Extremely efficient plating anode accelerates the deposition of the plating material

Excellent thermal performance

High durability

- Product Description

Product Introduction

Welcome to our product page for Titanium Anodes for Steel Plate Tinning. At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we pride ourselves on delivering advanced electrochemical materials, specifically designed to enhance the efficiency and quality of steel plate tinning processes. Our titanium anodes are crafted with precision, ensuring superior performance in various industrial applications.

Product Specifications

System Category | Coating Type | Current density (A/m2) | Dimensions |

Micro-etching liquid | Iridium Tantalum Mixed Oxide | 200-400 | All can be customized |

Alkaline etching solution | Iridium Tantalum/Lead Dioxide | 100-300 | All can be customized |

Acid etching solution | Ruthenium-iridium mixed oxide | 300-500 | All can be customized |

|  |  |

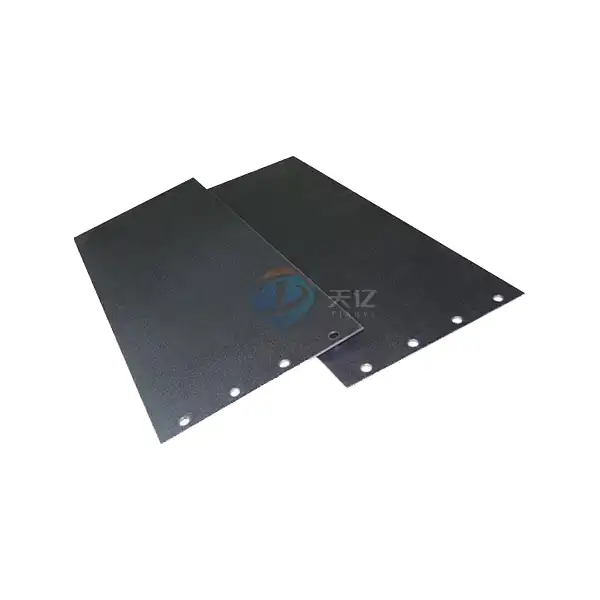

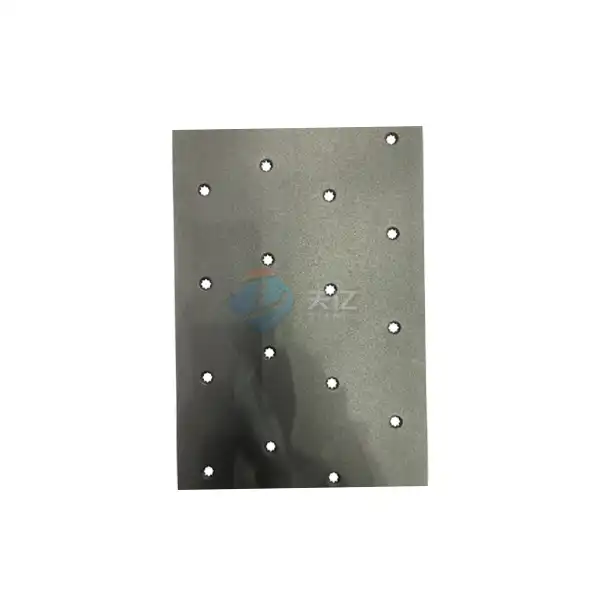

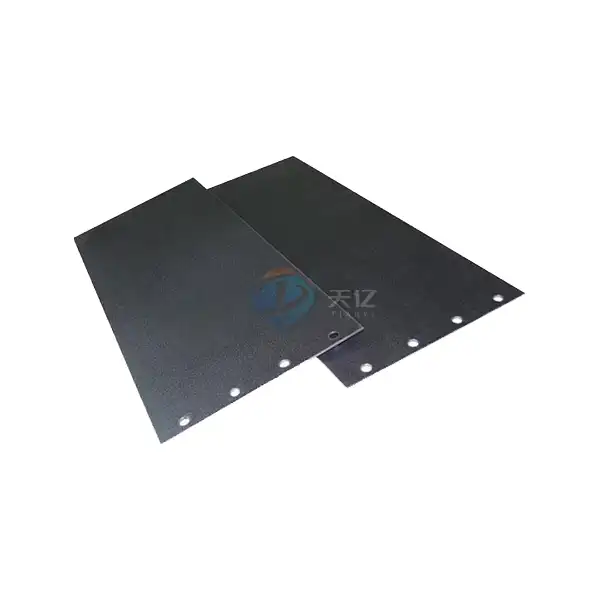

Product Composition and Design

Our Titanium Anodes for Steel Plate Tinning are constructed from high-quality titanium alloys coated with Mixed Metal Oxide (MMO). This combination enhances the anode's durability and corrosion resistance, making it ideal for demanding environments. The design allows for optimal current distribution, ensuring efficient tinning processes.

Product Advantages

- Corrosion Resistance: Titanium's inherent resistance to corrosion prolongs the lifespan of our anodes.

- High Efficiency: Optimized design minimizes energy consumption during the tinning process.

- Customizable: Tailored solutions to meet specific client requirements.

- Eco-Friendly: Our products support sustainable manufacturing practices.

Technical Features

- Robust Construction: Built to withstand harsh electrochemical conditions.

- Low Maintenance: Designed for minimal upkeep, reducing operational costs.

- Wide Compatibility: Suitable for various steel plate tinning setups.

Product Application

Our Titanium Anodes for Steel Plate Tinning are essential for industries involved in steel plate tinning, particularly in:

Electronics Industry: Precision is essential in electronics, and electroplating anodes help achieve flawless coatings on delicate components, enhancing their durability and performance.

Automotive Industry: Electroplating anodes are key to producing durable, corrosion-resistant coatings and polished chrome finishes, contributing to both the functionality and aesthetics of automotive parts.

Aerospace Industry: Aerospace applications require components to withstand extreme conditions. Electroplating anodes are crucial for producing parts that meet the strict standards for quality and durability in this sector.

Jewelry and Decorative Arts: Electroplating anodes enable the creation of beautiful, long-lasting finishes on jewelry and decorative items, ensuring their quality and visual appeal.

Medical Devices: For medical devices, electroplating provides corrosion-resistant and hygienic surfaces, ensuring the safety, reliability, and longevity of critical medical instruments.

Oil and Gas Industry: Electroplating anodes are essential for applying protective coatings that enhance the corrosion resistance and longevity of equipment used in challenging oil and gas environments.

Renewable Energy: In renewable energy systems, electroplated components benefit from enhanced durability and efficiency, contributing to the reliability of sustainable energy solutions.

Agriculture: Electroplating adds wear and corrosion resistance to components used in agricultural machinery, improving their durability under tough working conditions.

Aviation Industry: Precision coatings achieved with electroplating anodes are essential for manufacturing reliable aircraft components that meet stringent aviation standards.

Textile Industry: Electroplating anodes provide durable coatings for textile machinery parts, boosting their performance and longevity in demanding operational settings.

Telecommunications: In telecommunications, electroplated components enable dependable connections and efficient signal transmission, ensuring network reliability.

General Manufacturing: Electroplating anodes support numerous manufacturing processes by enhancing the quality and lifespan of items, from fasteners to industrial equipment, across various sectors.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

The process begins with selecting high-purity titanium, known for its excellent corrosion resistance and mechanical strength, essential for the steel plate tinning process. The chosen titanium must meet stringent quality standards to ensure optimal performance.

Substrate Preparation

The titanium is then cut into the required shapes and dimensions, typically utilizing methods like laser cutting or water jet cutting. This ensures that the anodes are tailored to fit specific applications in steel plate tinning.

Surface Cleaning

Prior to coating, the titanium surfaces undergo a rigorous cleaning process. This includes degreasing and removing any oxides or contaminants through chemical baths and abrasive blasting. This step is crucial to enhance adhesion for subsequent coatings.

Coating Application

A mixed metal oxide (MMO) coating is applied to the titanium substrate. This coating enhances the anode's electrochemical performance and extends its lifespan. Methods such as thermal spraying or electrochemical deposition may be employed for an even and robust coating.

Curing Process

Following coating application, the anodes are subjected to a curing process. This typically involves heating the anodes to facilitate proper bonding between the titanium substrate and the MMO layer, ensuring durability under operating conditions.

Quality Control

Stringent quality control checks are conducted throughout the production process. Tests for coating thickness, adhesion strength, and electrical conductivity are performed to ensure that the anodes meet industry specifications and performance standards.

Dimensional Inspection

Each titanium anode undergoes a thorough dimensional inspection to confirm that it adheres to the required specifications. This ensures that the anodes will perform optimally when utilized in steel plate tinning operations.

Final Surface Treatment

A final surface treatment may be applied to optimize the performance of the titanium anodes. This can involve additional cleaning or passivation to improve the electroplating characteristics necessary for effective tinning.

Packaging

Once all quality checks are completed, the titanium anodes are carefully packaged using protective materials to prevent damage during transport. Proper packaging is vital to maintain the integrity of the anodes until they reach the customer.

Documentation

Each shipment includes detailed documentation, such as specifications, handling instructions, and operational guidelines. This information assists customers in effectively utilizing the titanium anodes for steel plate tinning.

Logistics and Shipping

The finished titanium anodes are shipped using reliable logistics services. Tracking information is provided to ensure timely and secure delivery to customers.

Technical Support

Manufacturers often offer ongoing technical support for customers, assisting with installation, operation, and troubleshooting related to the titanium anodes. This support ensures that users can maximize the performance of the anodes in their steel plate tinning processes.

Through this meticulous production process, titanium anodes for steel plate tinning are produced to meet high standards of quality and reliability, ensuring their effectiveness in enhancing the tinning process in steel manufacturing.

Quality Inspection

Each titanium anode undergoes thorough quality inspections, including:

- Dimensional Checks: Ensuring compliance with specifications.

- Performance Testing: Verifying operational efficiency under various conditions.

- Corrosion Resistance Tests: Confirming longevity in electrochemical applications.

Packaging Method

Our Titanium Anodes for Steel Plate Tinning are packaged securely to prevent damage during transportation. Custom packaging options are available to meet specific client needs, ensuring safe delivery worldwide. We recognize the importance of safeguarding our products from potential perils during transit. Damaged products can result in losses and negatively impact brand credibility. Therefore, we invest in quality packaging materials, such as robust boxes and cushioning materials like bubble wrap or foam inserts, to ensure a snug fit and prevent movement during shipping .

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, allowing clients to customize their anodes in terms of size, coating, and packaging. Our team collaborates closely with clients to deliver tailored solutions that meet exact specifications. Our commitment to customization is evident in our ability to work with you to develop anode rods that are not only tailored to your market's needs but also designed to withstand the rigors of industrial use. We pride ourselves on providing solutions that enhance your product line without compromising on quality or performance. By leveraging our advanced manufacturing techniques and strict quality control measures, we ensure that each anode rod is produced to the highest standards. Whether you need rods for cathodic protection, electrochemical processes, or other specialized applications, our team is dedicated to delivering products that meet and exceed your expectations.

FAQ

Q: How long do titanium anodes last?

A: Our titanium anodes can last up to 10 years, depending on usage conditions.

Q: Can I customize the size of the anodes?

A: Yes, we provide fully customizable sizes to meet your specific requirements.

Q: What industries use titanium anodes?

A: Our anodes are used in automotive, construction, and electronics industries, among others.

Contact Us

For more information on our Titanium Anodes for Steel Plate Tinning or to discuss your specific needs, please contact us at [info@di-nol.com]. Let Shaanxi Tianyi be your trusted partner in advanced electrochemical technologies!

YOU MAY LIKE

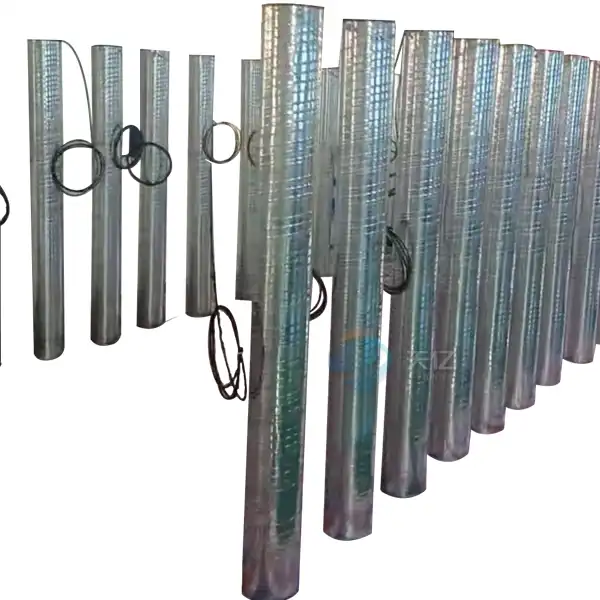

VIEW MOREMMO/Ti Linear Anode

VIEW MOREMMO/Ti Linear Anode VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating

VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating VIEW MOREICCP MMO Canister Anode

VIEW MOREICCP MMO Canister Anode VIEW MORETitanium Anode For Steel Plate Galvanizing

VIEW MORETitanium Anode For Steel Plate Galvanizing VIEW MORETitanium Anode For PCB Electroplating

VIEW MORETitanium Anode For PCB Electroplating_1731396613400.webp) VIEW MOREElectrode for electro-oxidation waste water treatment

VIEW MOREElectrode for electro-oxidation waste water treatment VIEW MOREtitanium electrode

VIEW MOREtitanium electrode VIEW MORETitanium Anode For Metal Electroplating

VIEW MORETitanium Anode For Metal Electroplating