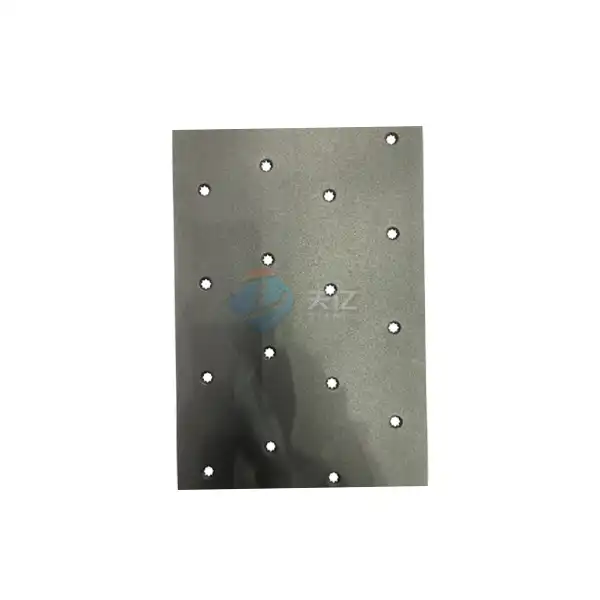

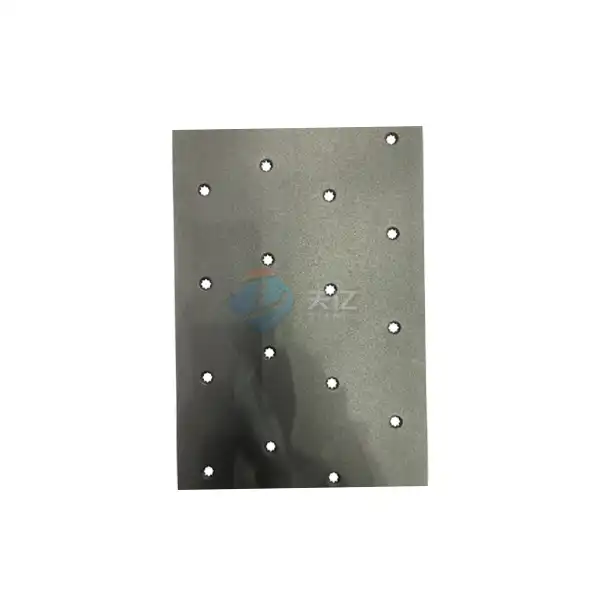

Titanium anode for hexavalent/trivalent chromium electroplating

Uniform current distribution deposits the plating material evenly and consistently

Extremely efficient plating anode accelerates the deposition of the plating material

Excellent thermal performance

High durability

- Product Description

Titanium Anode for Hexavalent/Trivalent Chromium Electroplating Introduction

Titanium anode for hexavalent/trivalent chromium electroplating are used in chromium electroplating, and can be coated with iridium oxide, ruthenium oxide, or mixed iridium tantalum oxide. These anodes are insoluble in the plating bath matrix and have the following benefits:

Inhibit oxidation

Titanium anodes with iridium mixed metal oxide coatings can inhibit the oxidation of Cr3+.

Ensure uniform plating

Titanium anodes provide excellent conductivity and stability, which can result in uniform and high-quality plating.

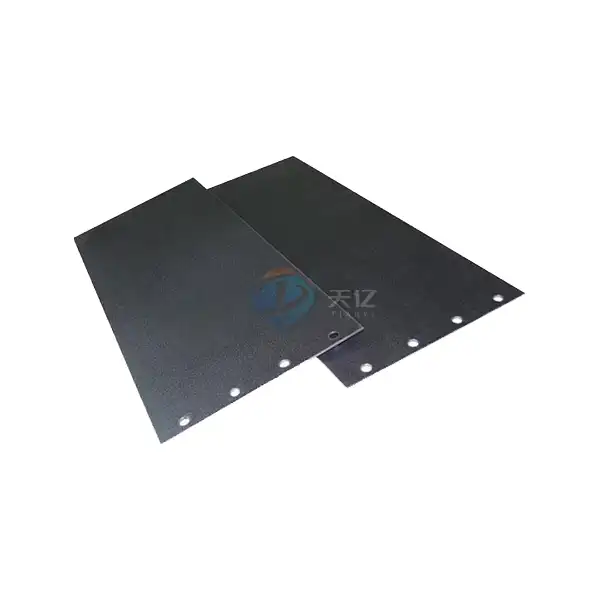

Lightweight and flexible

Mixed-metal oxide (MMO) coated titanium anodes are lightweight and geometrically flexible, and can be refurbished multiple times.

Product Specifications

System Category | Coating Type | Current density (A/m2) | Dimensions |

Micro-etching liquid | Iridium Tantalum Mixed Oxide | 200-400 | All can be customized |

Alkaline etching solution | Iridium Tantalum/Lead Dioxide | 100-300 | All can be customized |

Acid etching solution | Ruthenium-iridium mixed oxide | 300-500 | All can be customized |

|  |

|  |

Product Composition and Design

Our Titanium anode for hexavalent/trivalent chromium electroplatings are composed of high-purity titanium substrates, coated with advanced MMO technology. This combination ensures excellent conductivity and resistance to corrosion, which is crucial in electroplating applications. The design of our anodes allows for optimal current distribution, minimizing the risk of localized corrosion and enhancing plating quality.

Product Advantages

- Enhanced Durability: Our titanium anodes exhibit superior resistance to corrosion and degradation, ensuring a longer service life.

- High Efficiency: The advanced coating technology improves current efficiency, resulting in faster plating times and reduced energy consumption.

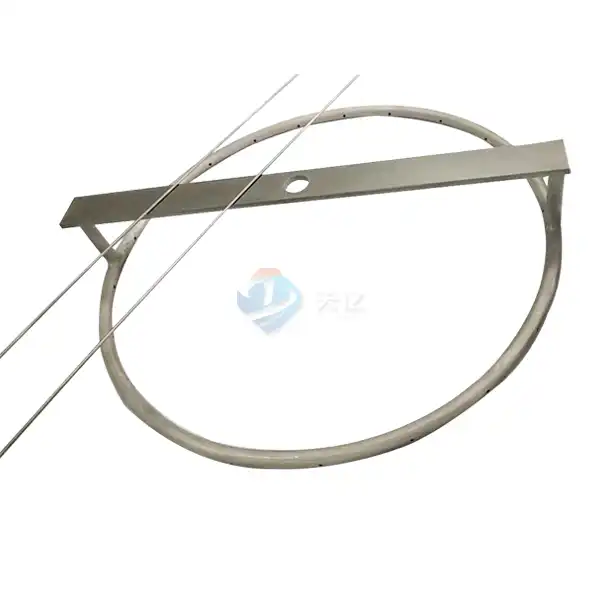

- Customizable Options: We offer customizable dimensions and configurations to meet the specific requirements of our clients.

- Eco-Friendly: Our anodes contribute to environmentally friendly electroplating processes by reducing waste and harmful emissions.

Technical Features

- Superior Conductivity: High conductivity ensures optimal performance during electroplating.

- Robust Coating: The MMO coating provides exceptional wear resistance and enhances the anode’s lifespan.

- Flexible Design: Capable of being tailored to various electroplating setups and requirements.

Product Application

Our Titanium anode for hexavalent/trivalent chromium electroplating are ideal for use in various electroplating processes, including:

Electronics Industry: Precision is essential in electronics, and electroplating anodes help achieve flawless coatings on delicate components, enhancing their durability and performance.

Automotive Industry: Electroplating anodes are key to producing durable, corrosion-resistant coatings and polished chrome finishes, contributing to both the functionality and aesthetics of automotive parts.

Aerospace Industry: Aerospace applications require components to withstand extreme conditions. Electroplating anodes are crucial for producing parts that meet the strict standards for quality and durability in this sector.

Jewelry and Decorative Arts: Electroplating anodes enable the creation of beautiful, long-lasting finishes on jewelry and decorative items, ensuring their quality and visual appeal.

Medical Devices: For medical devices, electroplating provides corrosion-resistant and hygienic surfaces, ensuring the safety, reliability, and longevity of critical medical instruments.

Oil and Gas Industry: Electroplating anodes are essential for applying protective coatings that enhance the corrosion resistance and longevity of equipment used in challenging oil and gas environments.

Renewable Energy: In renewable energy systems, electroplated components benefit from enhanced durability and efficiency, contributing to the reliability of sustainable energy solutions.

Agriculture: Electroplating adds wear and corrosion resistance to components used in agricultural machinery, improving their durability under tough working conditions.

Aviation Industry: Precision coatings achieved with electroplating anodes are essential for manufacturing reliable aircraft components that meet stringent aviation standards.

Textile Industry: Electroplating anodes provide durable coatings for textile machinery parts, boosting their performance and longevity in demanding operational settings.

Telecommunications: In telecommunications, electroplated components enable dependable connections and efficient signal transmission, ensuring network reliability.

General Manufacturing: Electroplating anodes support numerous manufacturing processes by enhancing the quality and lifespan of items, from fasteners to industrial equipment, across various sectors.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process involves several critical stages:

Material Selection

Choose high-purity titanium (Grade 2 or Grade 5) as the base material for its excellent strength-to-weight ratio and corrosion resistance.

Cutting and Shaping

Cut the titanium sheets or rods to the desired dimensions using precision CNC machines to ensure uniformity and accuracy in shape.

Surface Preparation

Clean the titanium surfaces using a combination of mechanical polishing and chemical etching to remove any surface contaminants. This step is crucial for ensuring proper adhesion of the subsequent coating.

Coating Application

Apply a mixed metal oxide (MMO) coating using thermal spraying or electroplating techniques. The MMO coating typically consists of a mixture of noble metals such as iridium and tantalum, which enhance electrochemical performance.

Control the coating thickness to between 10 to 50 microns, ensuring optimal conductivity and durability.

Quality Inspection

We implement stringent quality control measures throughout the production process, including:

- Raw material inspections

- Coating thickness assessments

- Performance testing to ensure compliance with specifications.

Packaging Method

Our packaging solutions prioritize safety and cost-effectiveness. Each anode is carefully packed to prevent damage during transportation, ensuring that they arrive at their destination in optimal condition. We clearly label fragile contents and provide explicit handling instructions to ensure that carriers and handlers exercise proper care during transit .

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, allowing our clients to customize the anodes according to their specific requirements. Our team collaborates closely with clients to develop tailored solutions that align with their production processes. Our commitment to customization is evident in our ability to work with you to develop anode rods that are not only tailored to your market's needs but also designed to withstand the rigors of industrial use.

FAQ

Q: What is the lifespan of your titanium anodes?

A: Our Titanium anode for hexavalent/trivalent chromium electroplating typically have a lifespan of over 5 years, depending on the application and usage conditions.

Q: Can you customize the anodes for specific electroplating processes?

A: Yes, we provide customizable solutions tailored to meet the specific requirements of our clients.

Q: Are your anodes environmentally friendly?

A: Absolutely. Our anodes contribute to eco-friendly electroplating processes by minimizing waste and harmful emissions.

Contact Us

For more information on our Titanium anode for hexavalent/trivalent chromium electroplating, please contact us at [info@di-nol.com]. Our team is ready to assist you with your electroplating needs and provide the best solutions tailored to your requirements.

YOU MAY LIKE

VIEW MORETitanium Wire Anode

VIEW MORETitanium Wire Anode VIEW MOREPlatinum-coated titanium electrode

VIEW MOREPlatinum-coated titanium electrode VIEW MORERuthenium oxide coated titanium anode

VIEW MORERuthenium oxide coated titanium anode VIEW MORETitanium Anode For Steel Plate Galvanizing

VIEW MORETitanium Anode For Steel Plate Galvanizing VIEW MORETitanium Anode For Steel Plate Tinning

VIEW MORETitanium Anode For Steel Plate Tinning VIEW MORETitanium Anode For PCB Electroplating

VIEW MORETitanium Anode For PCB Electroplating VIEW MORETitanium Anode For Metal Electroplating

VIEW MORETitanium Anode For Metal Electroplating