FIP Titanium Anode For Copper Foil Electrolysis

Maximum recovery

High-precision metal extraction

Environmental sustainability

High versatility

- Product Description

Product Introduction

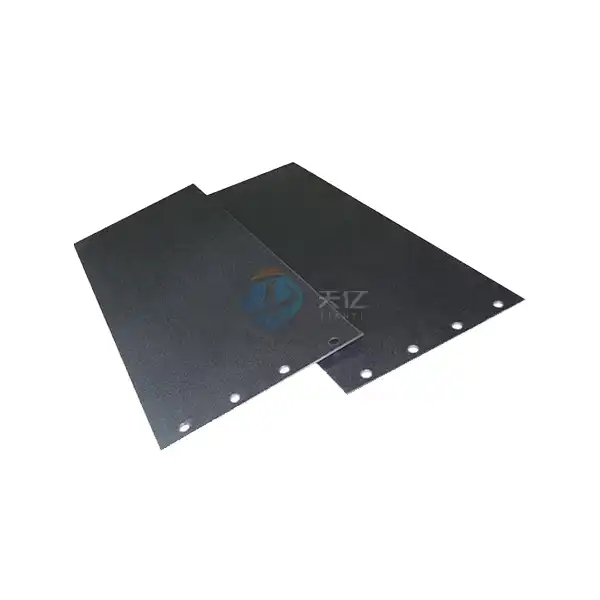

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. We are proud to present our FIP Titanium Anode for Copper Foil Electrolysis. This high-performance anode is specifically designed to enhance the electrolysis process in copper foil production, ensuring high efficiency and longevity. Our expertise in electrochemical materials guarantees that our products meet the most stringent industry standards.

Product Specifications

Substrate: Gr1/Gr2 Pure Titanium ASTM265

Coating: Ir-Ta

Operation Current: 5000-8000A/m2

Electrolyte:Cu2+:50-150g/L,

H2SO4:60-150g/L

Cl-:30-60ppm

Additives: 2-5ppm

Operation temperature:50-80℃

Lifespan: More than 8 month

|  |

|  |

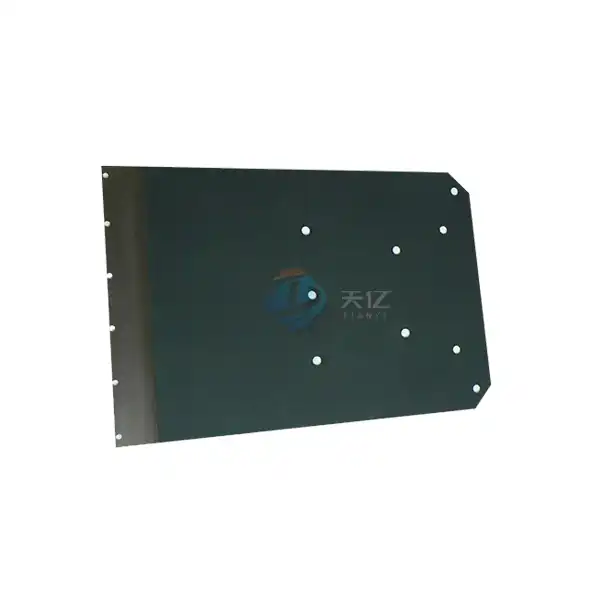

Product Composition and Design

Our FIP Titanium Anode for Copper Foil Electrolysis are crafted from high-grade titanium alloys and coated with a proprietary MMO layer. This advanced coating enhances the anode's electrical conductivity and resistance to corrosion, making it ideal for demanding electrolysis applications. The design is optimized for maximum surface area to improve efficiency and reduce operational costs.

Product Advantages

- High Efficiency: Our anodes are designed to facilitate optimal electrolysis, significantly increasing copper deposition rates.

- Durability: The robust construction and advanced coating technology ensure long-lasting performance, reducing the need for frequent replacements.

- Eco-Friendly: Our production processes prioritize environmental responsibility, aligning with global sustainability goals.

- Customization: We offer tailored solutions to meet specific requirements, ensuring compatibility with various electrolysis systems.

Technical Features

- Electrochemical Stability: Our titanium anodes maintain stable performance over extended periods, even under challenging conditions.

- Low Overpotential: Designed to minimize energy losses during operation, our anodes help optimize energy consumption in the electrolysis process.

- Enhanced Corrosion Resistance: The MMO coating significantly extends the anode's lifespan, making it suitable for various industrial applications.

Product Application

FIP Titanium Anode For Copper Foil Electrolysis is widely used for metal deposition such as copper, nickel, cobalt, manganese, chromium, zinc, etc.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Material Selection

The production of FIP (Fluorine-Impregnated Polymer) titanium anodes begins with selecting high-purity titanium as the base material. The titanium is chosen for its excellent corrosion resistance, mechanical strength, and ability to withstand the electrolysis environment.

Titanium Rod Preparation

The titanium is processed into rods or sheets, depending on the required specifications for the FIP titanium anode. This may involve cutting, grinding, and machining to achieve precise dimensions, ensuring compatibility with electrolysis equipment.

Surface Treatment

To enhance adhesion and performance, the titanium surface undergoes treatment, which may include sandblasting or acid etching. This treatment improves the surface roughness and prepares it for the subsequent fluorine impregnation process.

Fluorine Impregnation

The key step in producing FIP titanium anodes involves the fluorine impregnation process. The titanium substrate is treated with a fluorine-based solution, allowing fluorine to penetrate the titanium surface. This process is critical for creating a protective layer that enhances the anode’s performance in electrolysis.

Coating Application

After fluorine impregnation, a conductive coating may be applied to the titanium substrate. This coating is usually a mixed metal oxide (MMO) layer, which improves the anode’s efficiency and longevity by facilitating better current distribution during the electrolysis process.

Curing Process

The coated anodes undergo a curing process, typically involving heat treatment. This step ensures that the fluorine and coating adhere properly to the titanium, enhancing their durability and effectiveness under operational conditions.

Quality Control Testing

Quality control is integral throughout the production process. Each batch of anodes is subjected to rigorous testing, including measurements of thickness, electrical conductivity, and resistance to corrosion. This ensures that the anodes meet specified performance criteria.

Final Inspection

A thorough final inspection is conducted to check for any defects or inconsistencies. This includes visual inspections and dimensional checks to confirm that the FIP titanium anodes meet the highest quality standards before packaging.

Packaging

Once approved, the anodes are carefully packaged to prevent damage during transportation. Packaging materials are selected to protect the anodes from physical impacts and environmental factors, ensuring they remain in optimal condition.

Documentation and Certification

Each package is accompanied by documentation detailing the anode's specifications, installation guidelines, and maintenance recommendations. This information is vital for users to ensure proper handling and effective use.

Shipping Logistics

The finished FIP titanium anodes are shipped to customers using reliable logistics providers. Customers receive tracking information to monitor their orders until delivery.

Post-Delivery Support

After delivery, manufacturers offer technical support to assist customers with installation, operation, and maintenance queries. This ensures that the FIP titanium anodes perform efficiently and effectively in copper foil electrolysis applications.

Through this comprehensive production process, FIP titanium anodes are engineered to deliver superior performance in copper foil electrolysis, significantly enhancing efficiency and longevity while minimizing maintenance needs.

Quality Inspection

Quality is our top priority. Each FIP Titanium Anode undergoes comprehensive inspections, including:

- Material Testing: Ensuring that only the highest quality titanium is used.

- Coating Thickness Measurement: Verifying the consistency and quality of the MMO coating.

- Functional Testing: Assessing performance parameters to meet or exceed industry standards.

Packaging Method

We understand the importance of safe and efficient packaging. Our titanium anodes are carefully packaged to prevent damage during transit. Our solutions include:

- Customized packaging options

- Moisture-proof and corrosion-resistant materials

- Secure handling for international shipping

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services. We collaborate closely with clients to develop bespoke solutions that meet their unique requirements. This includes customized designs, sizes, and packaging to ensure that our products fit seamlessly into your processes.

FAQ

Q1: What is the lifespan of the FIP Titanium Anode?

A1: Our FIP Titanium Anode for Copper Foil Electrolysis typically have a lifespan of approximately 5,000 hours, depending on operating conditions.

Q2: Can I get customized sizes?

A2: Yes, we provide tailored solutions to meet specific dimensions and requirements.

Q3: Are these anodes environmentally friendly?

A3: Absolutely! We are committed to sustainable practices in our production processes.

Q4: What industries benefit from using these anodes?

A4: They are widely used in the copper foil industry, electronics manufacturing, and renewable energy sectors.

Q5: How do I order?

A5: Please contact us via the information below to discuss your requirements.

Contact Us

For more information on our FIP Titanium Anode for Copper Foil Electrolysis, please reach out to us at [info@di-nol.com]. Our dedicated team is ready to assist you with any inquiries and provide you with the best solutions tailored to your needs.

YOU MAY LIKE

VIEW MOREdsa coating titanium anode

VIEW MOREdsa coating titanium anode VIEW MOREelectrolysis titanium electrode

VIEW MOREelectrolysis titanium electrode_1731398246364.webp) VIEW MOREMMO Tubular String Anode

VIEW MOREMMO Tubular String Anode VIEW MOREDisc Anode

VIEW MOREDisc Anode VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil

VIEW MOREIr-Ta Titanium Anode for Electrolytic Copper Foil_1731229210902.webp) VIEW MORETitanium Anode For PCB Etching Solution

VIEW MORETitanium Anode For PCB Etching Solution VIEW MORETitanium Mesh Anode For Water Treatment

VIEW MORETitanium Mesh Anode For Water Treatment_1731642483124.webp) VIEW MOREMicro acidic electrolyzed water generator

VIEW MOREMicro acidic electrolyzed water generator