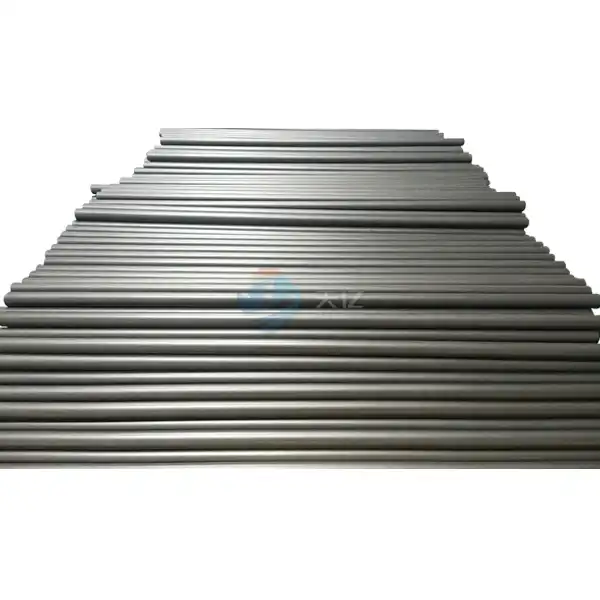

MMO Tubular String Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

Welcome to our product page for the MMO Tubular String Anode! Designed for efficiency and durability, our product is engineered to enhance performance across various electrochemical applications. Utilizing advanced materials and manufacturing processes, this anode is perfect for industries requiring reliable and effective solutions, including electroplating, cathodic protection, and water treatment.

Product Specifications

Outer diameter (mm)/customizable | Length (mm)ke / can be customized | Output current(A) | Life expectancy (years) |

19 | 1200 | 7.2 | 20-50 |

25 | 500 | 4 | 20-50 |

25 | 1000 | 8 | 20-50 |

25 | 1200 | 10 | 20-50 |

25 | 1500 | 12 | 20-50 |

32 | 1200 | 12 | 20-50 |

Product name: Anode tube with cable

Cable type: 16m ²* 8mtr Length XLPE/PVC,single core

Specifications: Φ 25 * 1000mm (customizable)

Wall thickness: 0.9mm

Coating system: Ru Ir mixed oxide, Ir Ta mixed oxide coating

Product use environment: fresh water, sea water, soil, tank bottom, cooler and other anti-corrosion and control

Output current: 8A

Base material grade: ASTM B-265 Grade1

Product service life: 20 years (customizable)

|  |

Product Composition and Design

The MMO Tubular String Anode features a robust design that maximizes surface area for optimal performance. The anode is coated with high-quality Mixed Metal Oxides (MMO), ensuring excellent conductivity and corrosion resistance. Our innovative design allows for easy installation and integration into existing systems.

Product Advantages

High Performance: Enhanced efficiency in electrochemical reactions, providing a higher output with lower energy consumption.

Durability: Built to withstand harsh conditions, our anodes exhibit superior longevity and minimal maintenance.

Versatility: Suitable for a variety of applications, from industrial electroplating to environmental protection measures.

Customization: We offer tailored solutions to meet specific client requirements, ensuring the best fit for every application.

Technical Features

Enhanced Conductivity: The MMO coating offers superior electrical conductivity, improving overall system efficiency.

Corrosion Resistance: Designed to resist corrosive environments, prolonging the lifespan of the anode.

Customizable Lengths and Diameters: Adaptable to fit various installation requirements.

Product Application

MMO tubular anode

Application areas: Suitable for many environments, such as soil, fresh water, saline water and seawater, and it is light in weight, has a long service life and is cost-effective.

1. MMO tubular anode is also called titanium tube anode, MMO anode titanium tube, or precious metal oxide (MMO) titanium anode tube. It is a metal oxide with electrocatalytic activity formed by coating, sintering and other processes on the titanium tube substrate. Suitable for many environments, such as soil, fresh water, saline water and seawater, and it is light in weight, has a long service life and is cost-effective;

2. In the application of impressed current cathodic protection, as the MMO auxiliary anode of the cathodic protection system, it constitutes a set of cathodic protection system together with a constant potential instrument, test pile, reference electrode, etc.;

3. In the process of using it as an auxiliary anode for deep well anode or bridge cathodic protection, weld the connecting cable to form a 2/3 anode string, which is simple to install and convenient to construct;

4. The service life and output current required by different requirements can be designed and produced by adjusting the coating ratio. MMO tubular anode coating type, thickness and anode size can be customized according to the user, depending on the required current density, medium environment and design life.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process involves:

Material Selection

Pure titanium tubes are chosen as the base material for their corrosion resistance and conductivity. The material must meet specific quality standards to ensure durability in harsh environments.

Tube Preparation

The titanium tubes are cut to the required length and then cleaned to remove any impurities. Surface preparation includes acid etching or sandblasting, which enhances the adhesion of the MMO coating.

Coating Application

A mixed metal oxide (MMO) coating, typically composed of iridium and tantalum oxides, is applied to the titanium tube surface. This coating serves as the catalyst, increasing electrical conductivity and extending the anode’s lifespan. The coating is applied through thermal spraying or a dipping process, followed by heat treatment for uniform adherence.

Assembly of Anode Strings

Individual tubular anodes are connected into a string formation with durable connecting wires. The wires are attached securely to ensure continuous electrical conductivity along the entire string.

Sealing and Insulation

Each tubular anode is sealed with insulating materials at connection points to prevent unintended current loss. This insulation is especially crucial in applications where the anode string is deployed underwater.

Current Distribution Testing

The anode string undergoes current distribution testing to confirm that the MMO coating ensures uniform conductivity across all tubular sections. This step is critical for effective cathodic protection in the final application.

Quality Control

Each anode string is inspected for coating quality, adhesion strength, and resistance to corrosion. Additionally, tests are conducted to ensure that the anode meets industry standards for electrochemical performance.

Packaging and Documentation

The anode string is packaged with care, accompanied by documentation that includes installation instructions, performance guidelines, and maintenance recommendations for optimal operation in cathodic protection systems.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. We conduct rigorous inspections at every production stage, ensuring each MMO Tubular String Anode meets our high standards for durability and performance. Our quality control process includes:

Raw material testing

Coating thickness verification

Performance assessments under simulated operating conditions

Packaging Method

We prioritize safe and efficient packaging to ensure your anodes arrive in perfect condition. Our packaging includes:

Protective cushioning to prevent damage during transit

Custom boxes designed to fit the product specifications

Eco-friendly materials to support our commitment to sustainability

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing you to customize products to your specifications. Whether you need unique sizes, coatings, or branding options, we can provide tailored solutions to meet your requirements.

FAQ

Q1: What is the product?

A1: It is a type of titanium anode coated with Mixed Metal Oxides, designed for various electrochemical applications.

Q2: How long do these anodes last?

A2: With proper maintenance, our anodes can last several years, depending on the application and environment.

Q3: Can I customize the size of the anodes?

A3: Yes, we offer customizable lengths and diameters to meet specific project needs.

Q4: What industries use it?

A4: They are used in industries such as electroplating, water treatment, and cathodic protection.

Q5: How can I order?

A5: Please contact us directly through the information below, and our team will assist you with your order.

Contact Us

For more data or to submit a request for the MMO Tubular String Anode, if it's not too much trouble, connect with us at info@di-nol.com. We're here to give you the best answers for your electrochemical necessities! Our MMO Cylindrical String Anodes are intended for outstanding toughness and proficiency, making them reasonable for many applications, including water treatment and modern cycles. Our accomplished group is focused on understanding your particular prerequisites and guaranteeing you get the right item to upgrade your tasks. We likewise offer specialized help and direction all through the requesting system, guaranteeing a consistent encounter beginning to end. Feel free to us today to examine your necessities or solicitation a statement!

YOU MAY LIKE

VIEW MORETitanium Wire Anode

VIEW MORETitanium Wire Anode VIEW MOREiccp protected mmo coated titanium anodes

VIEW MOREiccp protected mmo coated titanium anodes VIEW MOREPowered Water Heater Anode Rod

VIEW MOREPowered Water Heater Anode Rod VIEW MORETubular Anode

VIEW MORETubular Anode VIEW MORETitanium Electrodes for Water Ionization

VIEW MORETitanium Electrodes for Water Ionization VIEW MOREICCP Tubular Anode

VIEW MOREICCP Tubular Anode VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating

VIEW MORETitanium anode for hexavalent/trivalent chromium electroplating VIEW MORETitanium Mesh Anode For Water Treatment

VIEW MORETitanium Mesh Anode For Water Treatment

_1731398246364.webp)