ICCP Tubular Anode

Efficient electrochemical process

Easy installation

Low maintenance

- Product Description

ICCP Tubular Anode Introduction

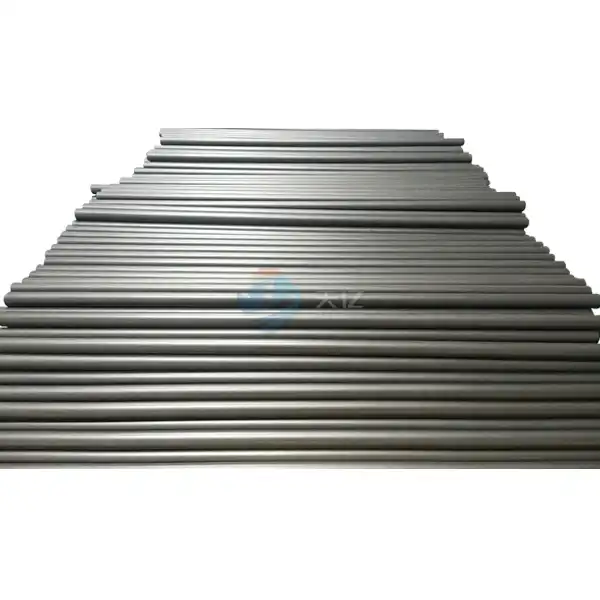

The ICCP Tubular Anode is a key component in Impressed Current Cathodic Protection (ICCP) systems, designed to protect metal structures, such as pipelines, underground tanks, marine structures, and other buried or submerged metallic assets, from corrosion. These tubular anodes are highly efficient and durable, making them ideal for long-term corrosion protection in harsh environments.

Product Specifications

Outer diameter (mm)/customizable | Length (mm)ke / can be customized | Output current(A) | Life expectancy (years) |

19 | 1200 | 7.2 | 20-50 |

25 | 500 | 4 | 20-50 |

25 | 1000 | 8 | 20-50 |

25 | 1200 | 10 | 20-50 |

25 | 1500 | 12 | 20-50 |

32 | 1200 | 12 | 20-50 |

Product name: Anode tube with cable

Cable type: 16m ²* 8mtr Length XLPE/PVC,single core

Specifications: Φ 25 * 1000mm (customizable)

Wall thickness: 0.9mm

Coating system: Ru Ir mixed oxide, Ir Ta mixed oxide coating

Product use environment: fresh water, sea water, soil, tank bottom, cooler and other anti-corrosion and control

Output current: 8A

Base material grade: ASTM B-265 Grade1

Product service life: 20 years (customizable)

|  |

Product Composition and Design

Our ICCP Tubular Anodes are made from high-quality titanium alloys, coated with a Mixed Metal Oxide (MMO) layer. This design ensures superior corrosion resistance and enhances the anode's longevity, making it suitable for harsh environmental conditions. The tubular shape allows for efficient current distribution, optimizing cathodic protection performance.

Product Advantages

High Durability: The use of titanium alloy and MMO coatings ensures exceptional resistance to corrosion and wear, providing a longer service life.

Customizable Options: We offer various lengths and diameters to meet specific project requirements, ensuring tailored solutions for every client.

Environmentally Friendly: Our anodes are designed to minimize environmental impact while providing effective protection.

Technical Features

Enhanced Conductivity: The MMO coating allows for better electron flow, improving the efficiency of the anode.

Lightweight Design: The titanium alloy construction ensures that the anodes are lightweight, facilitating easier installation and handling.

Corrosion Resistance: Designed to withstand even the most aggressive environments, ensuring that your assets are protected over time.

Product Application

MMO tubular anode

Application areas: Suitable for many environments, such as soil, fresh water, saline water and seawater, and it is light in weight, has a long service life and is cost-effective.

1. MMO tubular anode is also called titanium tube anode, MMO anode titanium tube, or precious metal oxide (MMO) titanium anode tube. It is a metal oxide with electrocatalytic activity formed by coating, sintering and other processes on the titanium tube substrate. Suitable for many environments, such as soil, fresh water, saline water and seawater, and it is light in weight, has a long service life and is cost-effective;

2. In the application of impressed current cathodic protection, as the MMO auxiliary anode of the cathodic protection system, it constitutes a set of cathodic protection system together with a constant potential instrument, test pile, reference electrode, etc.;

3. In the process of using it as an auxiliary anode for deep well anode or bridge cathodic protection, weld the connecting cable to form a 2/3 anode string, which is simple to install and convenient to construct;

4. The service life and output current required by different requirements can be designed and produced by adjusting the coating ratio. MMO tubular anode coating type, thickness and anode size can be customized according to the user, depending on the required current density, medium environment and design life.

Be used in a wide range of industries.

Water treatment

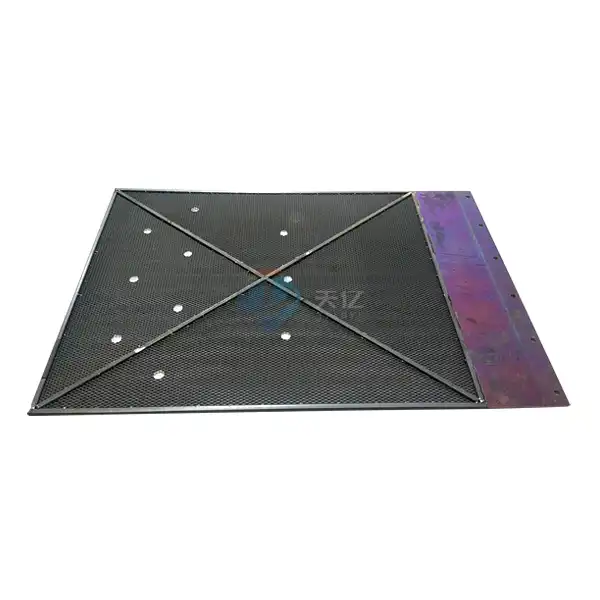

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process follows strict quality control measures to guarantee the highest product standards. Key steps include:

Material Selection

Titanium is selected as the primary material due to its corrosion resistance and conductive properties. The material undergoes thorough quality checks to ensure it meets the standards for ICCP applications, especially for use in marine and buried structures.

Tube Cutting and Preparation

The titanium tubes are cut to precise lengths based on the design specifications for ICCP systems. The tubes are then cleaned and treated with an acid etch or sandblasting process to create a roughened surface, enhancing the adhesion of the coating applied later.

Mixed Metal Oxide (MMO) Coating Application

A layer of MMO, typically a blend of iridium and tantalum oxides, is applied to the tube surface. This coating significantly improves conductivity and provides longevity in corrosive environments. The coating process involves dipping the tubes in MMO solution or spraying them, followed by heat treatment to cure the coating and secure it to the titanium.

Electrical Connections

Once coated, the tubes are equipped with durable, corrosion-resistant electrical connections. High-quality cable and sealing materials are used to ensure that the anode can withstand the harsh environments where it will be deployed.

Testing for Conductivity and Durability

Each anode undergoes extensive testing for conductivity to verify that the MMO coating provides uniform current distribution. Additional tests for adhesion, corrosion resistance, and overall durability ensure that the anode meets industry standards for ICCP systems.

Assembly of Anode Strings

In applications where multiple tubular anodes are needed, the tubes are assembled into strings with flexible wiring to allow for easy deployment. The connections are insulated to prevent current loss and to maintain system efficiency.

Insulation and Sealing

Protective seals are applied at the ends of each anode tube and along connecting points. These seals help prevent water ingress and corrosion, which could compromise the anode’s performance over time.

Quality Inspection

Each ICCP Tubular Anode undergoes rigorous quality inspections at every stage of production. This includes:

Raw Material Testing: Ensuring only the best materials are used.

In-Process Inspections: Regular checks during manufacturing to maintain quality.

Final Product Testing: Comprehensive testing to confirm compliance with industry standards.

Packaging Method

We prioritize safety and efficiency in our packaging methods. Our products are securely packed to prevent damage during transportation. Options include:

Custom Crates: For bulk orders, ensuring protection against impact.

Moisture-Proof Materials: To prevent corrosion during shipping.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services tailored to meet your specific requirements. Our team collaborates with you to design and produce our products that align with your project specifications, ensuring high performance and reliability.

FAQ

Q: What is the lifespan of them?

A: Our anodes are designed for a life expectancy of up to 20 years under optimal conditions.

Q: Can these anodes be customized?

A: Yes, we provide customizable options for length, diameter, and coating types to meet your needs.

Q: How do I install them?

A: Installation guidelines are provided with each order, ensuring proper setup for effective performance.

Contact Us

For more data on our ICCP Tubular Anodes or to demand a statement, if it's not too much trouble, contact us at info@di-nol.com.

_1731918881191.webp)

_1731398246364.webp)

_1731642168251.webp)