anodic coating titanium

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

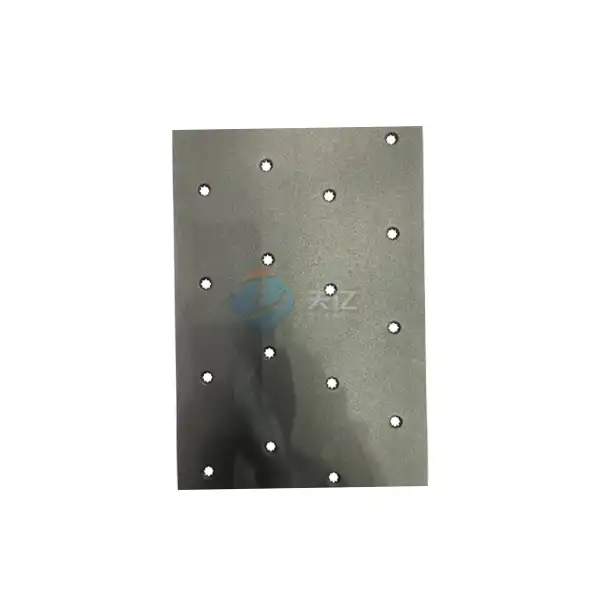

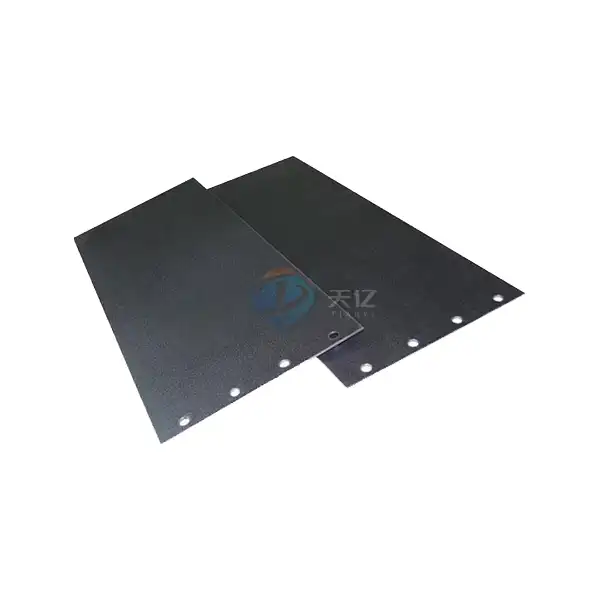

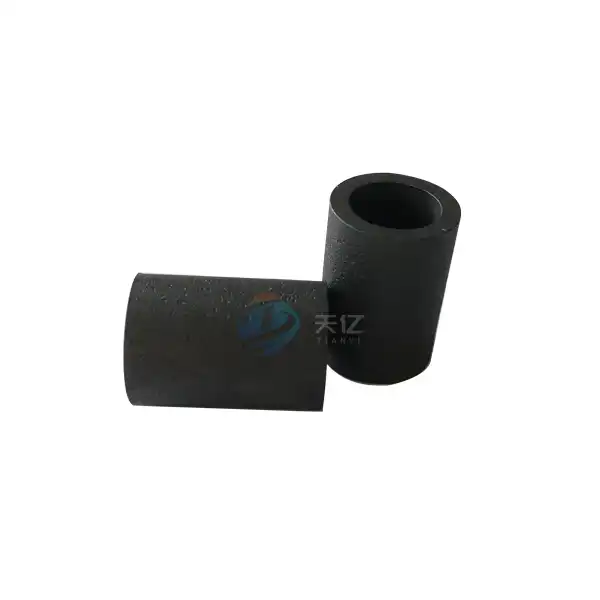

Customizable geometry of oxide-coated titanium anodes

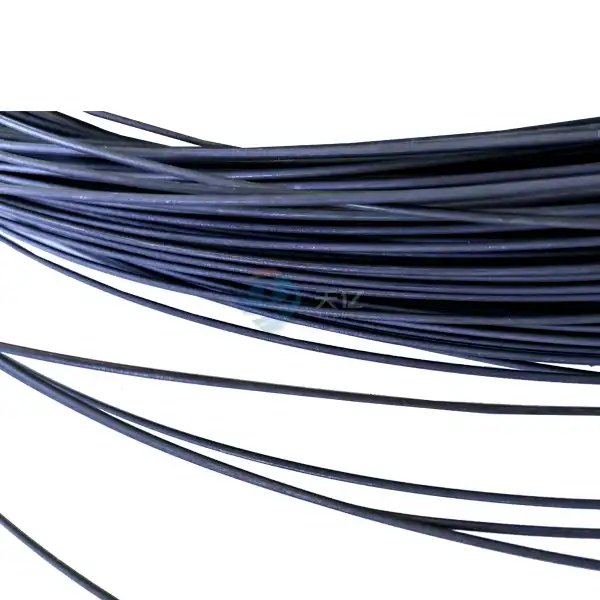

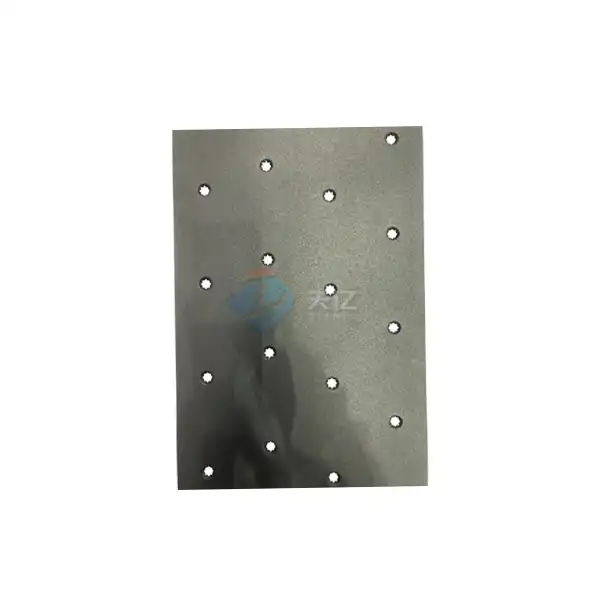

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. Our anodic coating titanium products are engineered for excellence in various electrochemical applications. Specializing in high-performance MMO (Mixed Metal Oxide) coated titanium anodes, we offer cutting-edge solutions that cater to diverse industries such as water treatment, metal processing, and disinfection.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

Our anodic coating titanium products feature a robust titanium base with advanced MMO coatings. This unique combination ensures exceptional durability, corrosion resistance, and performance across various environments. Our design focuses on flexibility, allowing us to customize dimensions and coatings to meet specific client needs.

Product Advantages

- Durability: Resistant to wear and corrosion, ensuring long-lasting performance.

- High Efficiency: Optimized for superior electrochemical reactions, enhancing operational efficiency.

- Customizable Solutions: Tailored coatings and dimensions to fit specific applications.

- Eco-Friendly: Supports sustainable practices in industrial processes.

Technical Features

Our anodic coating titanium is engineered to provide:

- Excellent Electrical Conductivity: This property enhances overall system performance and allows for faster reaction rates, making it ideal for a wide range of electrochemical applications.

- Reduced Energy Consumption During Operation: This not only lowers operational costs for users but also contributes to more sustainable practices by minimizing the environmental impact associated with high energy usage.

- Compatibility with Various Electrolytic Environments: The product is engineered to be compatible with a wide range of electrolytic environments, making it versatile for different applications.

- Minimal Maintenance Requirements: With a focus on durability and reliability, the system is designed to require minimal maintenance. This feature reduces downtime and operational disruptions, allowing users to focus on their core activities while enjoying long-lasting performance without frequent service interventions.

Product Applications

Our anodic coating titanium products are widely utilized in:

1. Electroplating

2. Aluminum foil production

3. Electrolytic copper foil production

4. Galvanized steel sheet

5. Water treatment

6. Cathodic protection

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our manufacturing process incorporates:

Material Selection

High-purity titanium substrates are chosen for anodic coating due to their excellent corrosion resistance and mechanical strength. The selection of titanium grade is crucial for achieving desired performance characteristics.

Surface Preparation

The titanium surfaces undergo a thorough cleaning process, including degreasing and mechanical polishing. This step is essential to remove contaminants and prepare the surface for uniform anodization, ensuring strong adhesion of the anodic coating.

Electrolyte Preparation

A suitable electrolyte solution is prepared, typically containing acids such as sulfuric or phosphoric acid. The concentration and temperature of the electrolyte are carefully controlled to optimize the anodizing process.

Anodizing Process

The titanium substrate is submerged in the electrolyte and connected to the anode in an electrochemical cell. An electric current is applied, causing the formation of a titanium oxide layer on the surface. The voltage and duration are controlled to achieve the desired coating thickness and properties.

Post-Anodizing Treatment

After anodization, the coated titanium is rinsed with distilled water to remove any residual electrolyte. This is often followed by sealing treatments, such as hot water sealing or dyeing, to enhance the protective qualities and aesthetic appearance of the coating.

Quality Control Testing

Finished anodic coatings undergo rigorous testing to assess their thickness, adhesion, and corrosion resistance. Various methods, including visual inspections and electrochemical tests, are employed to ensure compliance with industry standards.

Final Inspection and Packaging

The anodized titanium products are inspected for defects and packaged in protective materials to prevent damage during transit. Each package includes product specifications, handling instructions, and safety guidelines for users.

Quality Inspection

We implement a comprehensive quality control system that includes:

- Material inspections before production

- In-process quality checks

- Final product testing to ensure compliance with industry standards.

Packaging Method

Our packaging solutions are designed to protect your products during transport. We use:

- Customized packaging for safe delivery

- Moisture-proof and durable materials

- Clear labeling for easy identification

|  |  |

Our Certificates

Our Team

|  |

OEM Service

At Shaanxi Tianyi, we offer comprehensive OEM services to meet your unique requirements. From product design to production, we collaborate closely with our clients to deliver tailored solutions that ensure performance and satisfaction.

FAQ

Q: What is the product?

A:They refers to titanium products coated with Mixed Metal Oxide (MMO) to enhance performance in electrochemical applications.

Q: How long does the service life of these anodes last?

A: Our products are designed for a service life of over 10 years, depending on application conditions.

Q: Can you customize dimensions and coatings?

A: Yes, we provide fully customizable solutions tailored to your specific needs.

Q: What industries benefit from your products?

A: Industries including water treatment, metal processing, and electroplating can significantly benefit from our products.

Contact Us

For more information about our anodic coating titanium products or to discuss your specific requirements, please reach out to us at [info@di-nol.com]. Our team is ready to assist you in finding the perfect solution for your needs.

_1731642483124.webp)