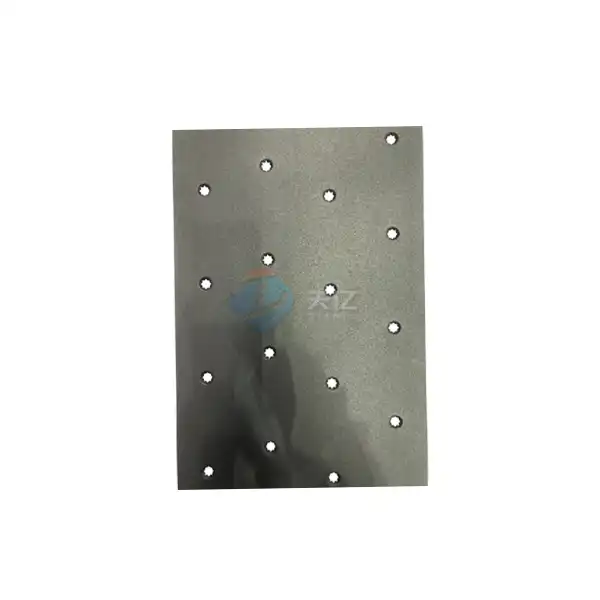

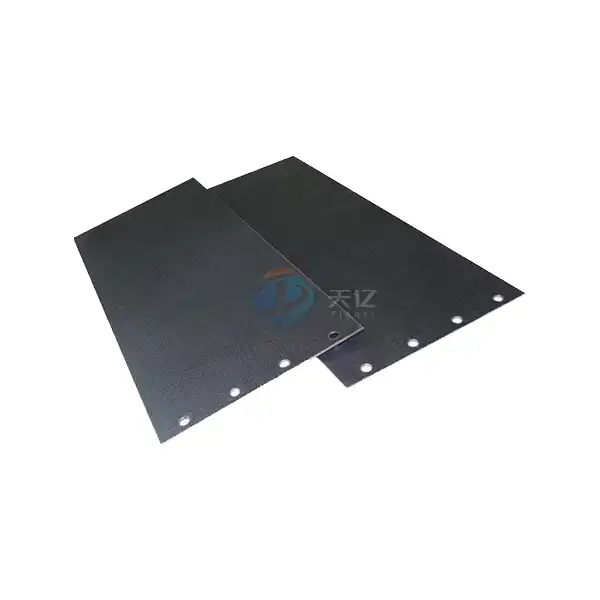

Ir-Ta oxide coated DSA electrode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

Welcome to our dedicated page for the Ir-Ta oxide coated DSA electrode, an advanced electrochemical solution designed for various industrial applications. This electrode, known for its durability and efficiency, is a preferred choice for those seeking high-performance materials in processes such as electrolysis, electroplating, and disinfection. With our commitment to quality and innovation, Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd. offers you a reliable product that meets the highest standards in the industry.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

The Ir-Ta oxide coated DSA electrode is made from high-quality titanium, providing a robust substrate for the mixed metal oxide coating of iridium and tantalum. This unique combination enhances the electrode's performance, ensuring longevity and efficiency in various applications. The design is customizable to meet specific operational requirements, making it suitable for diverse industrial settings.

Product Advantages

- High Durability: The Ir-Ta coating offers exceptional corrosion resistance, prolonging the electrode's lifespan.

- Enhanced Efficiency: Optimized for high current densities, this electrode maximizes performance in electrochemical processes.

- Customizable Options: Tailor the dimensions and coating thickness to fit your unique application needs.

- Eco-Friendly Solution: Contributes to environmentally friendly practices in water treatment and electrolysis.

Technical Features

- Stable Performance: The electrode maintains consistent performance over extended periods, even under challenging conditions.

- Low Operating Costs: Designed to minimize energy consumption while maximizing output, providing cost-effective solutions for users.

- Compatibility: Works seamlessly with various electrolytic cells and systems, enhancing operational flexibility.

Product Application

The Ir-Ta oxide coated DSA electrode is utilized across multiple industries, including:

1. Electroplating

2. Aluminum foil production

3. Electrolytic copper foil production

4. Galvanized steel sheet

5. Water treatment

6. Cathodic protection

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process adheres to strict quality standards, involving:

Material Selection

High-grade titanium substrates are chosen for their strength and corrosion resistance, which are critical for durability in harsh electrochemical environments. The selection of titanium alloy is tailored to meet specific application needs.

Surface Preparation

The titanium substrates undergo thorough cleaning and surface preparation. This includes degreasing, grit blasting, and chemical etching to create a rough surface that enhances adhesion for the oxide coating.

Preparation of Iridium and Tantalum Oxides

Pure iridium and tantalum oxide powders are prepared in predetermined ratios. The composition is carefully designed to optimize the electrochemical properties and stability of the resulting DSA electrode.

Coating Application

The prepared Ir-Ta oxide mixture is applied to the cleaned titanium substrate using methods such as thermal spraying or electrochemical deposition. This process is controlled to ensure even coverage and the desired thickness of the coating.

Curing and Sintering

Following the application, the coated electrodes undergo a sintering process at high temperatures in a controlled atmosphere. This step enhances the bonding strength between the oxide layer and the titanium substrate, ensuring durability.

Electrochemical Performance Testing

Each electrode is subjected to extensive electrochemical performance testing to evaluate parameters such as current efficiency, stability, and catalytic activity under simulated operational conditions. This testing verifies compliance with performance standards.

Final Inspection

After testing, the electrodes are carefully inspected for any defects, including uneven coatings or surface anomalies. This quality assurance step is critical for maintaining high product standards.

Packaging and Documentation

Once approved, the Ir-Ta oxide coated DSA electrodes are packaged in protective materials to prevent damage during transport. Each package includes product specifications, handling instructions, and safety information for users.

Quality Inspection

Quality is our top priority. Each product is subjected to comprehensive inspections, including:

- Visual Checks: For surface quality and coating integrity.

- Performance Testing: Assessing current density and efficiency under simulated operational conditions.

- Durability Tests: Evaluating resistance to corrosion and thermal stability.

Packaging Method

We utilize secure and eco-friendly packaging solutions to ensure the electrodes are protected during transit. Our packaging options include:

- Custom Foam Inserts: To prevent damage during shipping.

- Waterproof Wrapping: To safeguard against moisture exposure.

- Labeling: Clear product identification and handling instructions.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers tailored OEM services for the Ir-Ta oxide coated DSA electrode, allowing you to customize:

- Specifications: Choose from various dimensions and coating thicknesses.

- Branding: Your company’s logo and branding can be incorporated into the packaging and products.

FAQ

Q1: What is the lifespan of the product?

A1: The lifespan can vary based on operating conditions but is typically several years with proper maintenance.

Q2: Can I customize the size of the electrode?

A2: Yes, we offer various standard sizes and can customize dimensions to meet your needs.

Q3: What are the recommended operating conditions for this electrode?

A3: It is recommended to operate within the specified current densities and temperatures for optimal performance.

Q4: How do I place an order?

A4: You can contact us directly via email or through our website for inquiries and orders.

Q5: Is there a warranty for the electrodes?

A5: Yes, we provide a warranty on our products. Details can be discussed during the ordering process.

Contact Us

For more information on the Ir-Ta oxide coated DSA electrode or to discuss your specific needs, please reach out to us at [info@di-nol.com]. We look forward to partnering with you to meet your electrochemical solutions!