dsa coating titanium anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

Customizable geometry of oxide-coated titanium anodes

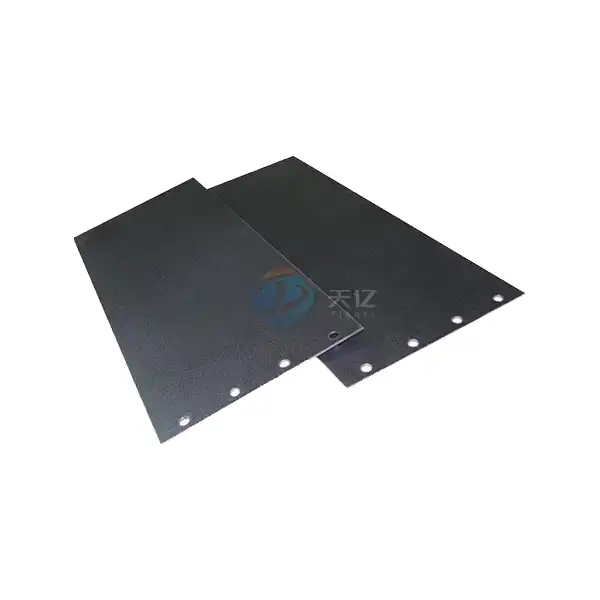

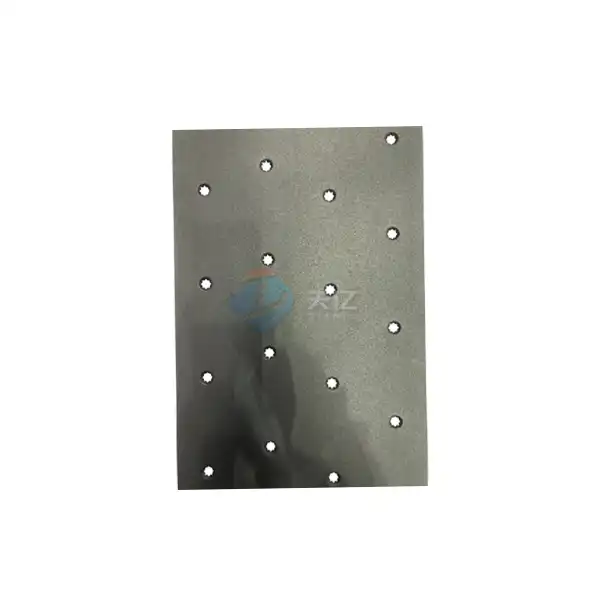

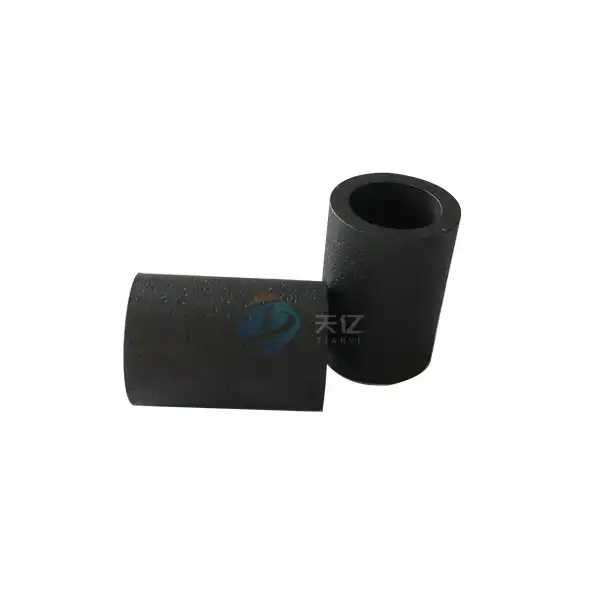

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Product Introduction

The DSA (Dimensionally Stable Anode) Coating Titanium Anode is engineered for optimal performance in various electrochemical applications. Our DSA titanium anodes are manufactured with advanced MMO (Mixed Metal Oxide) coatings, offering enhanced durability and efficiency in processes such as electroplating, cathodic protection, and water treatment. With a focus on sustainability and reliability, these anodes are designed to meet the rigorous demands of modern industries.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

Our DSA coating titanium anodes feature a carefully designed composition that enhances their electrochemical properties. The titanium substrate ensures high corrosion resistance, while the MMO coating provides superior conductivity and long service life. This combination makes our anodes ideal for demanding applications where reliability is crucial.

Product Advantages

- Durability: The robust design and high-quality materials ensure a long lifespan, even in harsh environments.

- Efficiency: Enhanced current distribution reduces energy consumption and improves overall system efficiency.

- Customization: We offer tailor-made solutions to meet specific client requirements, ensuring optimal performance.

- Eco-Friendly: Our anodes are produced with sustainable practices, contributing to environmental protection efforts.

Technical Features

- Electrochemical Stability: The DSA coating exhibits excellent stability under a wide range of operational conditions.

- Low Overpotential: Achieves high performance with minimal voltage loss, reducing operational costs.

- Versatile Applications: Suitable for various electrochemical processes, including water treatment and metal processing.

Product Applications

The DSA coating titanium anode is widely used in:

1. Electroplating

2. Aluminum foil production

3. Electrolytic copper foil production

4. Galvanized steel sheet

5. Water treatment

6. Cathodic protection

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process involves several key steps to ensure the highest quality:

Substrate Selection

High-quality titanium substrates are selected for DSA (Dimensionally Stable Anode) coatings due to their superior mechanical strength and corrosion resistance, which are essential for long-term durability in electrochemical applications.

Surface Preparation

The titanium substrates undergo rigorous surface preparation, including degreasing, sandblasting, and chemical etching. This process removes contaminants and enhances surface roughness, improving adhesion for the DSA coating.

Coating Material Preparation

A mixture of metal oxides, typically including ruthenium oxide, iridium oxide, or tantalum oxide, is prepared. These oxides are chosen for their excellent electrochemical properties and stability, contributing to the anode's overall performance.

Coating Application

The prepared oxide mixture is applied to the titanium substrate using techniques such as thermal spraying, sputtering, or electrochemical deposition. Careful control of application parameters ensures a uniform coating thickness and optimal coverage.

Curing Process

The coated anodes undergo a curing process, which often involves heating in a controlled atmosphere. This step promotes the formation of a strong bond between the metal oxides and the titanium substrate, enhancing the stability of the coating.

Performance Testing

Each DSA titanium anode is rigorously tested for electrochemical performance, including measuring current efficiency and operational stability. These tests ensure that the anodes meet strict performance standards required for their intended applications.

Final Inspection

After performance evaluation, the coated anodes are inspected for defects, such as uneven coatings or surface imperfections. This final quality check guarantees that only products meeting high standards are packaged.

Packaging and Documentation

Once approved, the DSA-coated titanium anodes are packaged in protective materials to prevent damage during transport. Accompanying documentation includes product specifications, handling guidelines, and safety information for users.

Quality Inspection

Quality is paramount at Shaanxi Tianyi. Our stringent quality control protocols include:

- Raw Material Testing: Ensuring only the best materials are used.

- In-Process Inspections: Monitoring production processes for consistency.

- Final Product Testing: Comprehensive evaluations to ensure compliance with industry standards.

Packaging Method

Our packaging solutions are designed to ensure the safe delivery of products. We use eco-friendly materials, and all items are securely packed to prevent damage during transportation. Custom packaging options are also available to meet client specifications.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, allowing clients to fully customize their DSA coating titanium anodes according to specific needs and applications. Our experienced team collaborates closely with each client to understand their unique requirements, ensuring that we design tailored solutions that not only meet but exceed their operational expectations. By leveraging our expertise and advanced technologies, we provide high-quality anodes that enhance performance and efficiency in various industrial processes, ultimately helping our clients achieve their goals more effectively. Whether you require specific dimensions, coating materials, or additional features, we are dedicated to delivering innovative and reliable products that cater to your precise specifications.

FAQ

Q: What is the lifespan of a DSA coating titanium anode?

A: With proper maintenance, our anodes can last several years, depending on the application and operating conditions.

Q: Can you provide custom sizes?

A: Yes, we offer customizable sizes and specifications to meet your specific requirements.

Q: Are your products environmentally friendly?

A: Yes, we prioritize sustainable production practices to minimize environmental impact.

Contact Us

For more information on our DSA Coating Titanium Anode or to discuss your specific needs, please contact us at [info@di-nol.com]. Our dedicated team is here to assist you with tailored solutions for your electrochemical applications.