Iridium tantalum oxide anode

Efficient oxygen generation

High durability and high electrocatalytic activity

Reusable

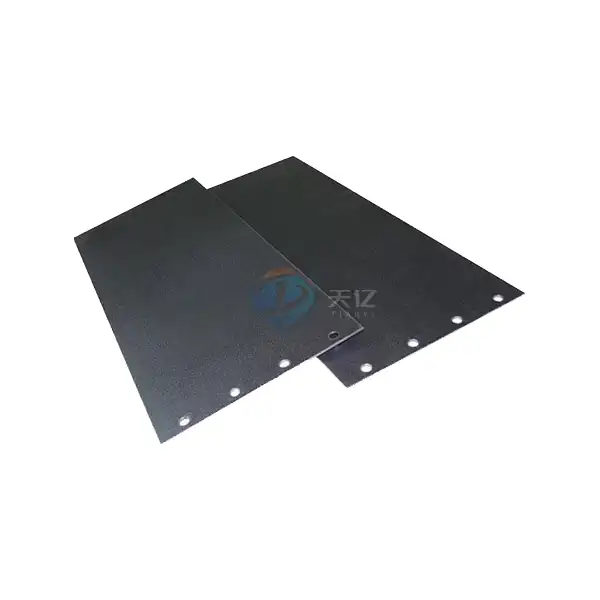

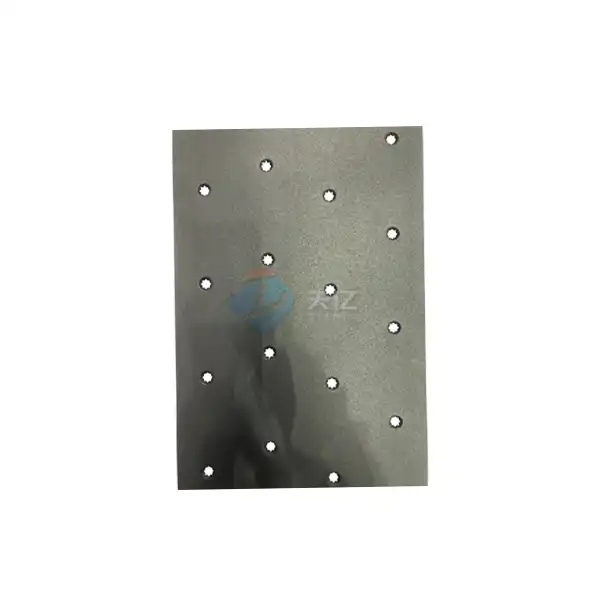

Customizable geometry of oxide-coated titanium anodes

Dimensional diversity for precision applications: rods, wires, pipes, plates, meshes, etc.

- Product Description

Iridium tantalum oxide anode Introduction

TianYI's Iridium Tantalum Oxide Anode offers exceptional performance for high-demand applications. With superior corrosion resistance, excellent electrical conductivity, and high chemical stability, our anode is ideal for industries such as energy storage, electronics, and aerospace. Choose TianYI for reliable and high-quality anode materials.

This anode features iridium tantalum coating and Grade 1 titanium, ensuring excellent corrosion resistance and high performance. It is customizable in shape and size, making it suitable for various applications in chemical, medical, and energy industries. The product is ISO9001 certified, ensuring quality and reliability.

Customizable Design:The anode can be tailored to nearly any shape and size based on your exact requirements, ensuring it fits perfectly with your specific equipment or application.

Material Quality:Made from Grade 1 titanium with a 99.6% Ti content and coated with iridium tantalum, it offers excellent corrosion resistance and durability, suitable for demanding environments.

Product Specifications

Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) |

Base metal | Gr1, Gr2 titanium |

Temperature range | <85 ℃ |

Current density | 500-800A |

Oxygen evolution potential | <1.45V |

Fluoride content | <50mg / L |

Precious metal content | 8-13g / m2 |

Coating thickness | 8-15μm |

PH value | 45303 |

Enhanced life | 300 H-400H |

Titanium anode shapes | plates, tubes, rods, wires, machined parts |

|  |  |  |

|  |  |  |

Product Composition and Design

The Iridium Tantalum Oxide Anode is constructed using a titanium substrate coated with a proprietary mixture of iridium and tantalum oxides. This unique composition enhances the anode's performance in electrolytic processes by improving conductivity and longevity. The design is engineered for maximum surface area to ensure efficient electrochemical reactions, making it a preferred choice for industries requiring high reliability.

Product Advantages

- High Durability: Engineered to withstand harsh chemical environments, ensuring long service life.

- Corrosion Resistance: Coated with iridium and tantalum to prevent degradation over time.

- Efficient Performance: Optimized for electrochemical reactions, enhancing overall system efficiency.

- Customization: Available in various sizes and specifications to meet specific customer requirements.

Technical Features

- Electrode Potential Stability: Maintains stable performance over prolonged use.

- Low Anodic Polarization: Minimizes energy consumption during operation.

- Robust Mechanical Strength: Withstands physical stresses in various applications.

Iridium Tantalum Oxide Anode Application

The Iridium Tantalum Oxide Anode is widely utilized in:

Ideal for a wide range of industries including water treatment, electroplating, and medical equipment, this anode supports various processes such as electroflotation, making it a versatile choice for different needs.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Our production process is meticulously managed to ensure the highest quality:

1.Material Selection

High-Purity Iridium and Tantalum: The process begins with selecting high-purity iridium and tantalum materials to ensure the quality and performance of the final anode.

2. Mixing

Precise Combination: The iridium and tantalum are precisely combined in specific ratios to achieve the desired chemical composition and properties.

3. Coating

Advanced Deposition Techniques: The mixed materials are then coated onto a substrate using advanced deposition techniques such as magnetron sputtering or thermal decomposition. This step ensures a uniform and adherent coating.

4. Annealing

Enhancing Material Properties: The coated substrate undergoes an annealing process, which involves heating it to high temperatures to enhance the material properties, such as electrical conductivity and chemical stability.

5. Quality Testing

Ensuring Specifications: Each batch of anodes is subjected to rigorous quality testing to ensure they meet the required specifications. This includes checking for uniformity, adhesion, and performance characteristics.

Packaging Method

Our anodes are packaged securely to prevent damage during transit. Each product is carefully wrapped and boxed, ensuring it arrives in perfect condition. We utilize eco-friendly materials to align with our commitment to sustainability.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

Shaanxi Tianyi offers comprehensive OEM services, allowing clients to customize the Iridium Tantalum Oxide Anode according to their specific needs. Whether you require alterations in size, shape, or coating specifications, our team is ready to assist.

FAQ

Q: What is the typical lifespan of the Iridium Tantalum Oxide Anode?

A: Under optimal conditions, our anodes can last several years, significantly reducing replacement frequency.

Q: Can these anodes be used in seawater applications?

A: Yes, they exhibit excellent corrosion resistance, making them suitable for seawater environments.

Q: Do you offer bulk purchasing options?

A: Absolutely! We provide competitive pricing for bulk orders. Please contact us for more details.

Contact Us

For further information or inquiries about the Iridium Tantalum Oxide Anode, please reach out to us at [info@di-nol.com]. Our dedicated team is here to assist you with all your needs!