Titanium Anode Tablets For Swimming Pool Disinfection

Higher current efficiency

Longer service life

No water pollution

Wide application range

- Product Description

Product Introduction

Welcome to a cleaner, safer swimming experience with our Titanium Anode Tablets for Swimming Pool Disinfection. These innovative tablets are designed to enhance the hygiene of your swimming pool while reducing the need for harsh chemicals. Utilizing advanced electrochemical technology, our titanium anode tablets help to effectively control algae, bacteria, and other contaminants, ensuring a crystal-clear swimming environment for you and your family.

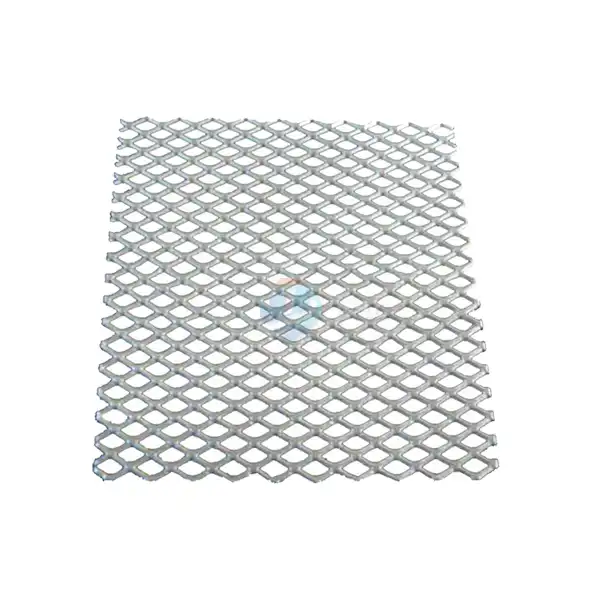

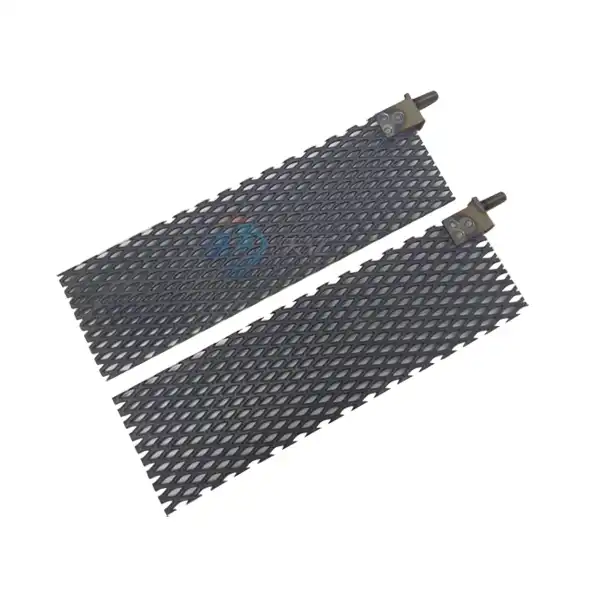

Product Show

Product Composition and Design

Our Titanium Anode Tablets for Swimming Pool Disinfection are composed of high-quality MMO-coated titanium, ensuring durability and effectiveness. The unique design allows for controlled dissolution in water, releasing active ingredients gradually to maintain optimal disinfection levels without overwhelming the pool's chemical balance.

Product Advantages

- Eco-Friendly: Reduces the need for chlorine and other harsh chemicals, making it safer for the environment.

- Long-Lasting: Each tablet provides sustained disinfection, ensuring your pool stays clean longer.

- Cost-Effective: Reduces overall chemical usage, leading to savings in pool maintenance costs.

- User-Friendly: Easy to use—simply drop the recommended number of tablets into your pool water.

Technical Features

- Electrochemical Activation: The tablets release ions that disrupt the cell walls of microorganisms, leading to their destruction.

- Customizable Use: Easily adjust the number of tablets based on pool size and water conditions for optimal results.

- Rapid Dissolution: Designed to dissolve efficiently, providing quick action against contaminants.

Product Application

Ideal for residential and commercial swimming pools, our titanium anode tablets are perfect for:

Chlor-alkali industrial water treatment, chlorine production, sodium hypochlorite electrolysis production,wastewater treatment and swimming pool cleaning.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

Our Workshop

Product Production Process

Raw Material Selection

Select high-grade titanium, typically Grade 1 or Grade 2, which is known for its excellent corrosion resistance and mechanical properties. Ensure the material meets industry standards for safety and effectiveness in swimming pool applications.

Tablet Design and Specifications

Define the specific dimensions and shape of the titanium anode tablets. Focus on optimizing size and surface area to maximize electrochemical activity for effective disinfection in swimming pools.

Powder Preparation

If required, prepare titanium powder through methods such as atomization or mechanical milling. Ensure the powder is of high purity and appropriate particle size for subsequent processing.

Tablet Forming

Use a powder compaction technique, such as hydraulic pressing or isostatic pressing, to form the titanium powder into tablet shapes. This step involves applying high pressure to achieve the desired density and structural integrity.

Sintering Process

Subject the pressed tablets to a sintering process at controlled temperatures in a vacuum or inert atmosphere. This step enhances the bonding between titanium particles, resulting in a dense and durable final product.

Surface Treatment

Perform surface treatment techniques, such as abrasive blasting or acid etching, to enhance the tablet surface. This improves the electrochemical properties and promotes better adhesion of any coatings.

Coating Application

Apply a mixed metal oxide (MMO) or noble metal coating on the titanium tablets to improve their performance in chlorine generation and enhance their lifespan. This coating can be applied through electroplating or other suitable deposition methods.

Curing Process

Cure the coated titanium anode tablets at specified temperatures to ensure proper bonding of the coating. This step is crucial for enhancing the durability and effectiveness of the tablets in pool disinfection applications.

Quality Control Testing

Conduct rigorous quality control assessments, including dimensional checks, surface integrity examinations, and electrochemical performance evaluations. Ensure that the tablets meet all necessary safety and performance standards.

Electrochemical Testing

Perform electrochemical tests in simulated pool conditions to evaluate the chlorine generation efficiency and stability of the titanium anode tablets. Assess their performance over time to ensure reliability during use.

Packaging and Labeling

Package the finished titanium anode tablets in protective materials to prevent damage during transport. Clearly label the packaging with product information, including specifications, usage instructions, and safety warnings.

Documentation and Certification

Provide detailed documentation that outlines technical specifications, installation guidelines, and maintenance instructions. Include any relevant certifications to assure customers of product quality and safety.

By following this comprehensive production process, manufacturers can ensure that titanium anode tablets for swimming pool disinfection are produced with high quality and performance, contributing effectively to maintaining water safety and cleanliness.

Quality Inspection

Each batch of titanium anode tablets undergoes rigorous quality inspection to guarantee:

- Consistency: Ensuring each tablet meets specified performance metrics.

- Purity: Testing for contaminants to provide a safe product.

- Performance: Evaluating the disinfection effectiveness to exceed industry standards.

Packaging Method

Our tablets are securely packaged in waterproof, moisture-proof bags to ensure their longevity and effectiveness. The packaging is designed for easy handling and storage, making it convenient for both consumers and retailers.

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We proudly offer comprehensive OEM services for our Titanium Anode Tablets for Swimming Pool Disinfection, enabling our clients to fully customize formulations, packaging, and branding to align with their specific market needs. Whether you require tailored sizes, precise dosages, or unique packaging designs, our dedicated team is here to assist you in creating a product that not only meets your specifications but also resonates with your customers. By collaborating closely with you throughout the process, we ensure that every aspect of your product reflects your brand's identity and fulfills market demands, ultimately enhancing your competitive edge.

FAQ

Q: How often should I use titanium anode tablets?

A: We recommend adding one tablet per 1000 liters of pool water every 1-2 weeks, depending on usage and environmental conditions.

Q: Are these tablets safe for all pool types?

A: Yes, our titanium anode tablets are safe for use in all types of swimming pools, including saltwater and freshwater systems.

Q: Can I use these tablets alongside traditional pool chemicals?

A: Yes, our tablets can be used in conjunction with other pool sanitizers to enhance overall effectiveness.

Contact Us

For more information about our Titanium Anode Tablets for Swimming Pool Disinfection, or to discuss your specific needs, please contact us at [info@di-nol.com]. Our dedicated team is here to help you find the perfect solution for your pool maintenance requirements.

YOU MAY LIKE

VIEW MOREelectroplating titanium electrode

VIEW MOREelectroplating titanium electrode VIEW MOREelectrolysis titanium electrode

VIEW MOREelectrolysis titanium electrode_1731380858183.webp) VIEW MORETitanium Anode For Slightly Acidic Electrolyzed Water

VIEW MORETitanium Anode For Slightly Acidic Electrolyzed Water VIEW MORETitanium Anode For Electrolyzed Oxidizing Water

VIEW MORETitanium Anode For Electrolyzed Oxidizing Water VIEW MORETitanium Anode For Sodium Hypochlorite Generator

VIEW MORETitanium Anode For Sodium Hypochlorite Generator_1731642120915.webp) VIEW MOREchlor alkali electrolyzer

VIEW MOREchlor alkali electrolyzer VIEW MORETitanium Anode Mesh For Swimming Pool Disinfection

VIEW MORETitanium Anode Mesh For Swimming Pool Disinfection_1731642483124.webp) VIEW MOREMicro acidic electrolyzed water generator

VIEW MOREMicro acidic electrolyzed water generator