titanium electrodes for salt water electrolysis

High electrocatalytic activity

Long and stable life

Reduced energy consumption costs

Reduced use of chemical agents

- Product Description

Titanium Electrodes for Salt Water Electrolysis Introduction

At Shaanxi Tianyi New Material Titanium Anode Technology Co., Ltd., we are proud to offer our high-performance titanium electrodes for salt water electrolysis. Designed for efficiency and reliability, our titanium electrodes play a crucial role in electrolysis processes, particularly in applications involving salt water, where they enhance the production of hydrogen and chlorine gases. Our electrodes are engineered to meet the rigorous demands of various industries, ensuring superior performance in water treatment, disinfection, and hydrogen generation.

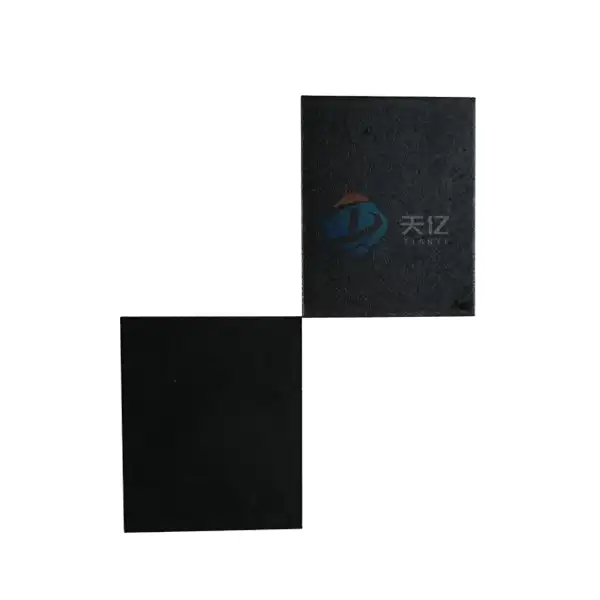

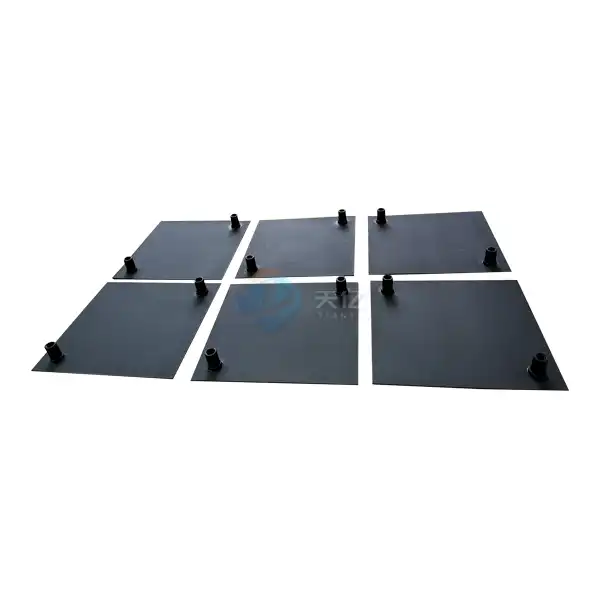

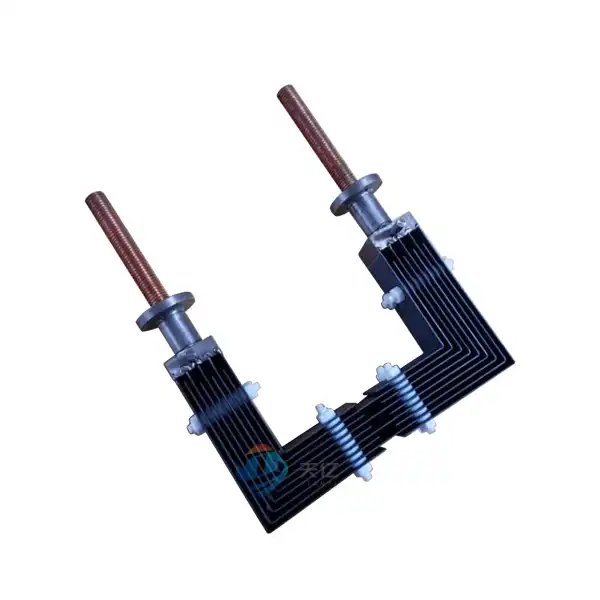

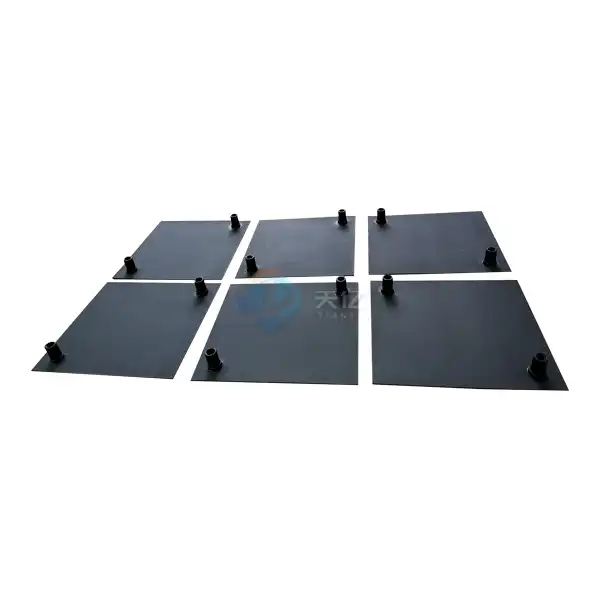

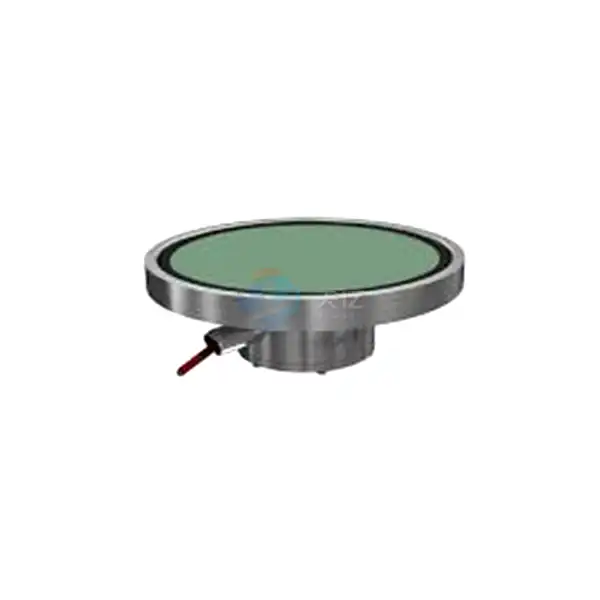

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

Product Composition and Design

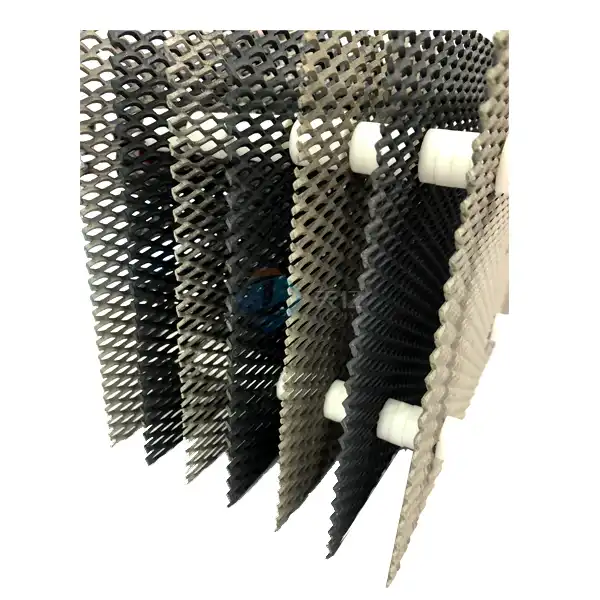

Our titanium electrodes are made from high-quality titanium alloy, featuring a Mixed Metal Oxide (MMO) coating that enhances corrosion resistance and electrical conductivity. The design ensures maximum surface area exposure, facilitating efficient electrolysis in salt water environments. Each electrode is customizable to meet specific client requirements, ensuring optimal performance in any application.

Product Advantages

- Corrosion Resistance: Our titanium electrode for salt water electrolysisresist the harsh conditions of salt water, ensuring long-term durability.

- High Efficiency: Designed to optimize electrolysis processes, improving hydrogen and chlorine production rates.

- Customizable Sizes: We provide tailored solutions to fit specific applications, ensuring maximum effectiveness.

- Environmentally Friendly: Our products contribute to sustainable practices in water treatment and disinfection.

Technical Features

- Advanced Coating Technology: Our MMO coating technology ensures exceptional longevity and performance.

- Temperature Resistance: The electrodes maintain functionality under varying temperature conditions, making them suitable for a wide range of environments.

- High Conductivity: Enhanced electrical properties ensure efficient operation and minimal energy loss during electrolysis.

Product Application

Our titanium electrode for salt water electrolysis for salt water electrolysis are used in various applications, including:

Municipal and Community Water Purification: MMO anodes are used to enhance water quality and safety in public water systems, effectively removing contaminants and supporting reliable water supplies.

Treatment of Cooling Systems: In industrial cooling water systems, MMO anodes prevent biofouling and corrosion, maintaining system efficiency and extending the lifespan of cooling equipment.

Swimming Pool and Spa Sanitation: MMO anodes help in disinfecting swimming pools and spas by generating necessary sanitizing agents, promoting clean and safe recreational water.

Marine Wastewater Management: Marine vessels and coastal facilities use MMO anodes to treat wastewater, ensuring environmental compliance and protecting marine ecosystems.

Sodium Hypochlorite Generation: MMO anodes facilitate the production of sodium hypochlorite, a widely-used disinfectant, through the electrochemical process, benefiting applications in sanitation and disinfection.

Cathodic Protection: MMO anodes are applied in cathodic protection systems to prevent corrosion in pipelines, storage tanks, and marine structures, helping to safeguard these assets from environmental damage.

Wastewater Treatment for Municipal Sewage: In sewage treatment plants, MMO anodes play a key role in breaking down pollutants, contributing to cleaner discharge and environmental sustainability.

Hospital Wastewater Processing: MMO anodes aid in the treatment of hospital wastewater, effectively reducing contaminants and ensuring safe water discharge that meets health standards.

Dye Industry Wastewater Treatment: Used in treating wastewater from dyeing processes, MMO anodes help in breaking down complex dye molecules, resulting in cleaner industrial discharge.

Industrial Cooling Water Maintenance: MMO anodes support industrial cooling water systems by reducing corrosion and scaling, preserving equipment and ensuring efficient system operation.

Electroplating Effluent Treatment: MMO anodes are essential in treating wastewater from electroplating processes, removing heavy metals and other contaminants to protect the environment.

Electro-Chlorination of Brine Water: In electro-chlorination systems, MMO anodes convert brine into chlorinated water, useful for disinfection in various applications, including water treatment and sanitation.

Desalination of Seawater: MMO anodes are used in seawater desalination plants to improve efficiency in salt removal processes, supporting the production of potable water from seawater sources.

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

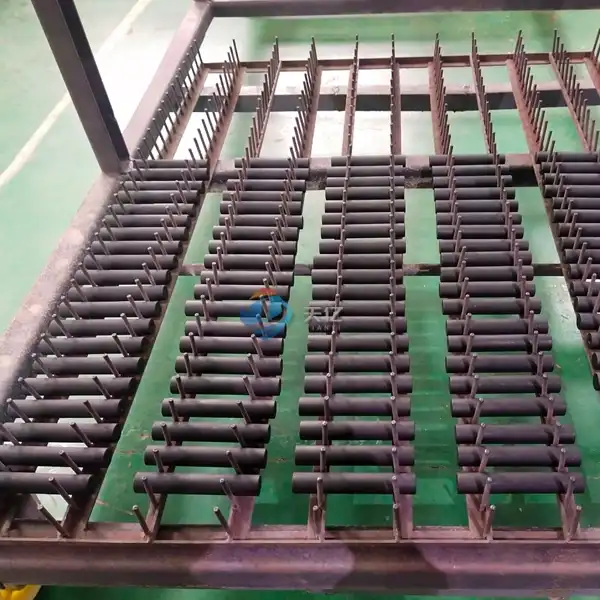

Our Workshop

Product Production Process

Material Selection

The process begins with the selection of high-purity titanium, often Grade 1 or Grade 2, known for its excellent corrosion resistance and strength, which are critical for electrodes used in saltwater electrolysis.

Cutting and Shaping

Titanium sheets are cut into specified dimensions using precision cutting methods such as laser cutting or water jet cutting. This ensures accurate shapes tailored to the electrolysis system’s requirements.

Surface Cleaning

The cut titanium substrates undergo a thorough cleaning process to remove any contaminants, oils, or dust. This typically involves ultrasonic cleaning in solvents, followed by rinsing with deionized water to prepare the surface for coating.

Surface Treatment

To improve coating adhesion and electrochemical performance, the cleaned titanium surfaces are treated through methods such as sandblasting or acid etching, creating a roughened surface that enhances bonding.

Coating Preparation

If required, a coating solution is prepared using mixed metal oxides (MMO) or other protective materials. This solution is designed to withstand the harsh conditions of saltwater electrolysis while enhancing electrode performance.

Coating Application

The prepared titanium electrodes are immersed in the coating solution and subjected to electrodeposition. An electrical current facilitates the uniform deposition of the coating, which can include oxides like ruthenium or iridium to enhance catalytic activity.

Coating Thickness Measurement

During the coating process, the thickness is continuously monitored using methods such as laser micrometers or X-ray fluorescence to ensure it meets specific performance criteria.

Post-Coating Cleaning

After coating, the electrodes are rinsed with deionized water to remove any residual chemicals or loose particles from the surface, ensuring a clean product ready for testing.

Electrochemical Performance Testing

Each titanium electrode undergoes rigorous testing to evaluate its electrochemical performance in saltwater conditions. Tests include measuring current efficiency, stability, and resistance to corrosion.

Final Inspection and Packaging

The electrodes are subjected to a final quality control inspection to ensure compliance with industry standards. Once approved, they are securely packaged with documentation that includes product specifications, handling guidelines, and compliance certifications, ready for shipment to customers.

Quality Inspection

Every titanium electrode undergoes rigorous quality inspections throughout the production process, including:

- Raw material testing

- Coating quality assessment

- Final product testing to ensure compliance with industry standards

Packaging Method

We prioritize safety and efficiency in our packaging solutions, ensuring that our titanium electrode for salt water electrolysis reach their destination intact. We employ packaging materials that offer robust protection against damage during transit without incurring unnecessary costs. This approach not only safeguards the integrity of the electrodes but also maintains economic viability, aligning with industry standards for efficient packaging practices.

Our packaging includes:

- Customized protective cases

- Moisture-resistant materials

- Clearly labeled for easy identification

|  |  |

Our Certificates

Our Team

|  |

OEM Service

We offer comprehensive OEM services, providing fully customized titanium electrodes for salt water electrolysis that meet your specific requirements. Our dedicated team collaborates closely with clients to ensure each product aligns perfectly with their needs.

FAQ

Q1: How long do the titanium electrodes last?

A1: Our electrodes typically last between 5-10 years, depending on usage conditions.

Q2: Can I customize the size of the electrodes?

A2: Yes, we offer customizable sizes to meet your specific application requirements.

Q3: Are your electrodes environmentally friendly?

A3: Absolutely! Our products are designed to support sustainable practices in various industries.

Contact Us

For more information about our titanium electrode for salt water electrolysis or to discuss your specific needs, please contact us at [info@di-nol.com]. Our team is ready to assist you with any inquiries and provide you with tailored solutions that meet your requirements.

YOU MAY LIKE

VIEW MOREWater heater power anode rod

VIEW MOREWater heater power anode rod VIEW MORETitanium Anode For Electrodialysis

VIEW MORETitanium Anode For Electrodialysis VIEW MOREtitanium electrodes for salt chlorinator

VIEW MOREtitanium electrodes for salt chlorinator_1731396613400.webp) VIEW MOREElectrode for electro-oxidation waste water treatment

VIEW MOREElectrode for electro-oxidation waste water treatment_1731642449066.webp) VIEW MOREAcidic oxidation potential water generator

VIEW MOREAcidic oxidation potential water generator_1731642168251.webp) VIEW MOREtitanium electrolyzer for electro-chlorination

VIEW MOREtitanium electrolyzer for electro-chlorination VIEW MOREMMO Disc Anodes

VIEW MOREMMO Disc Anodes VIEW MORETitanium Mesh Anode For Water Treatment

VIEW MORETitanium Mesh Anode For Water Treatment